Continuous chemical vapor deposition furnace and working method thereof

A chemical vapor deposition, deposition furnace technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of inconsistent product quality, failure to reach deposition temperature, long preparation time, etc. Uniformity, time saving, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

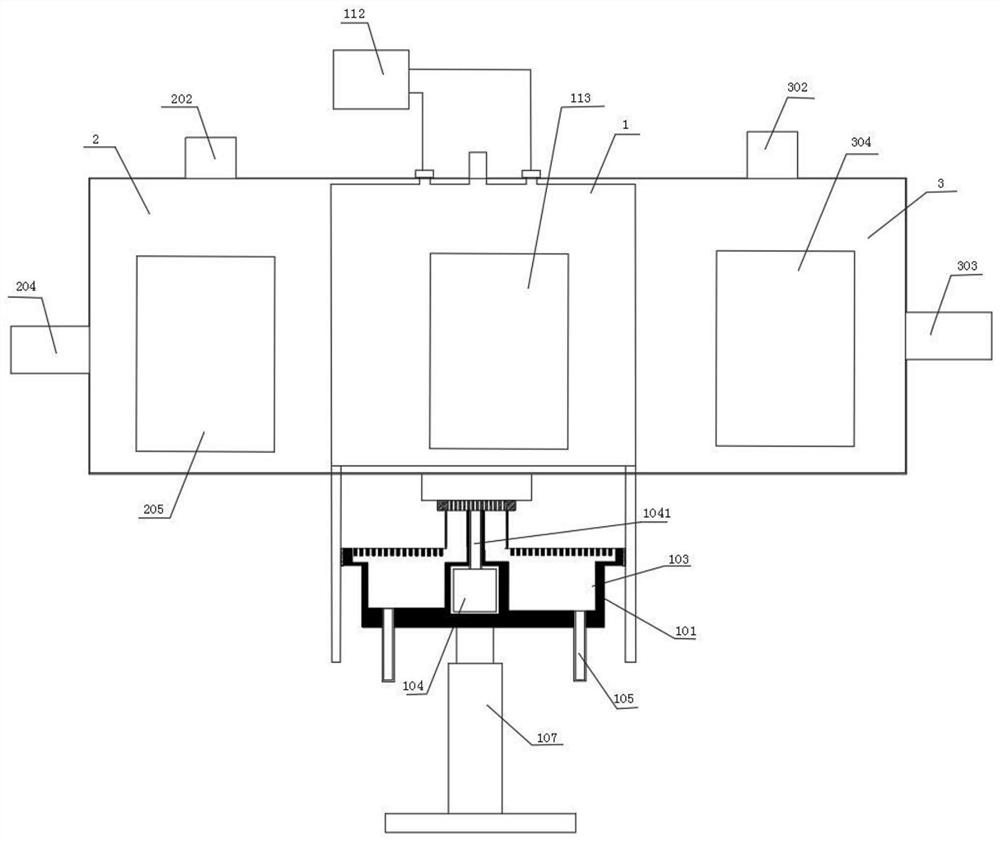

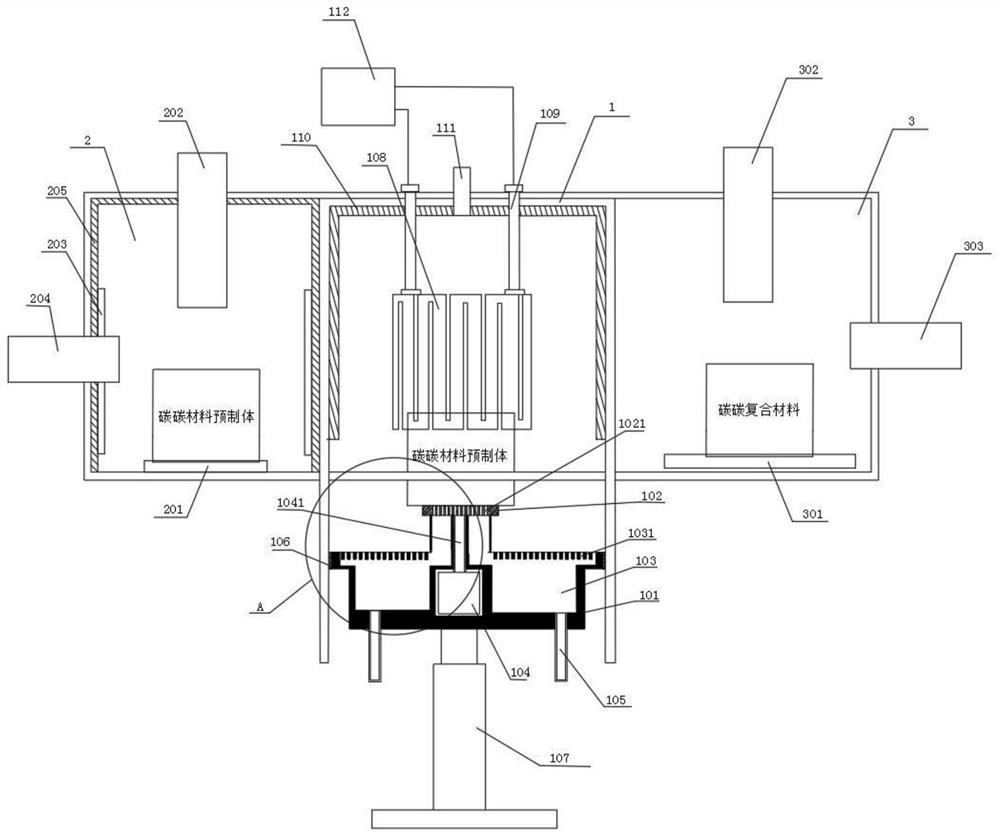

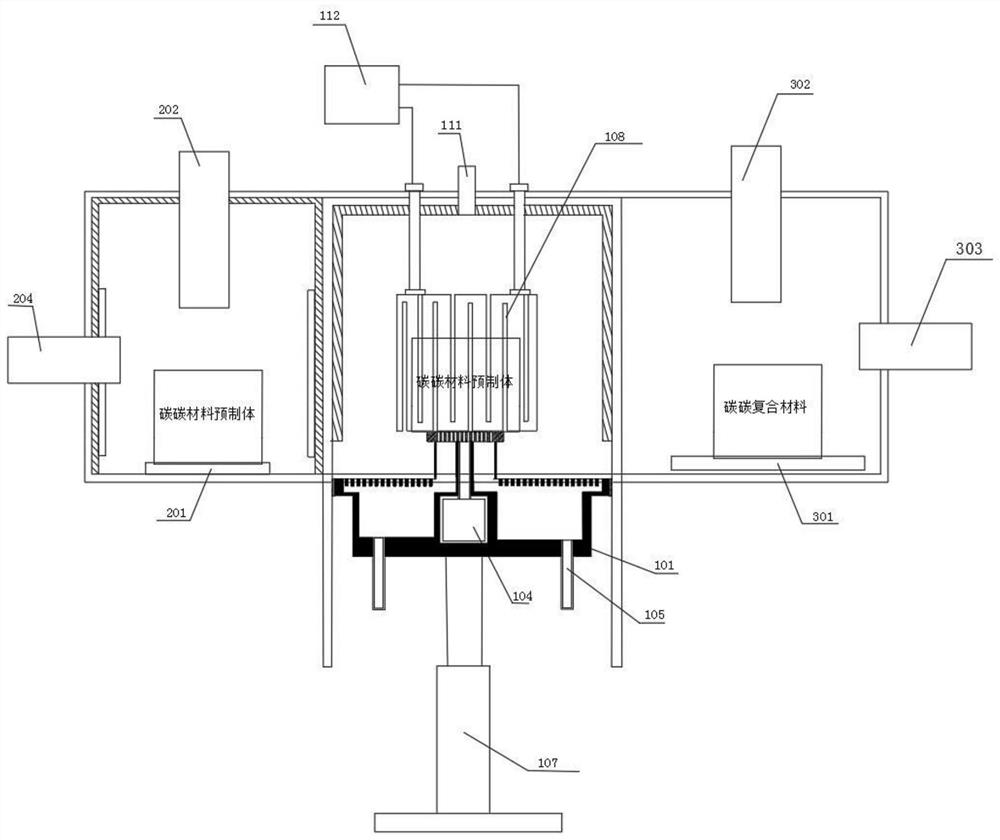

[0038] see Figure 1-5 As shown, in a continuous chemical vapor deposition furnace of the present invention, the deposition furnace is successively divided into a preparation area 2, a deposition area 1 and a cooling area 3 by partitions;

[0039] The deposition area 1 includes a furnace body, a lifting platform 101 installed below the furnace body and moving up and down in the furnace cavity of the furnace body, a rotating platform 102 arranged on the upper surface of the lifting platform 101 for carrying preforms, and a rotating platform 102 installed on the lifting platform 101. The power box in the inside, the lifting mechanism 107 that is arranged under the lifting table 101 for lifting the lifting table 101, the heater 108 or the induction coil that is installed on the upper part of the furnace cavity and corresponds to the rotating carrier table 102; There is a rotating mechanism 104, and the rotating mechanism 104 is provided with a rotating shaft 1041 connected to the...

specific Embodiment 2

[0054] The difference between this specific embodiment and embodiment 1 is that

[0055] Wherein, the heater 108 adopts any one of a circular integral heater, a circular splicing heater, a square integral heater or a square splicing heater; the preferred circular splicing heater in this embodiment; the heater 108 is made of graphite, carbon For other high temperature resistant materials such as carbon or tungsten molybdenum, carbon-carbon material is preferred in this embodiment; the rotary bearing table 102 adopts an axial flow type or a non-axial flow type, and this embodiment is preferably an axial flow type, which is a prior art and needs no further description.

[0056] Beneficial effect:

[0057] 1. The continuous chemical vapor deposition furnace of the present invention adopts a continuous structure consisting of a preheating zone, a deposition zone and a cooling zone, and it can be achieved that the same deposition furnace has three preparations in three zones at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com