Antibacterial and antiviral coating and preparation method thereof

An anti-virus and coating technology, applied in wax coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor quality and unstable performance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An antibacterial and antiviral coating, comprising the following substances in corresponding parts by weight:

[0031] 75 parts of film-forming resin, 10 parts of emulsion, 6 parts of film-forming aid, 0.5 part of defoamer, 0.5 part of wetting agent, 4 parts of modified filler, 2 parts of antibacterial additive, 0.1 part of amine neutralizer.

[0032] The film-forming resin is styrene-acrylic resin; the emulsion is paraffin wax emulsion; and the film-forming aid is n-butanol.

[0033] The preparation method of modified filler is as follows:

[0034] 1) put the kaolin into the calciner for calcining treatment, and take it out after 1 hour;

[0035] 2) Carry out graded grinding treatment to the kaolin treated in step 1), and grade the kaolin after the proportioning is completed for subsequent use;

[0036] 3) Immerse the graded kaolin obtained in step 2) into a silane coupling agent, filter out and dry to constant weight.

[0037] During the calcination process in step...

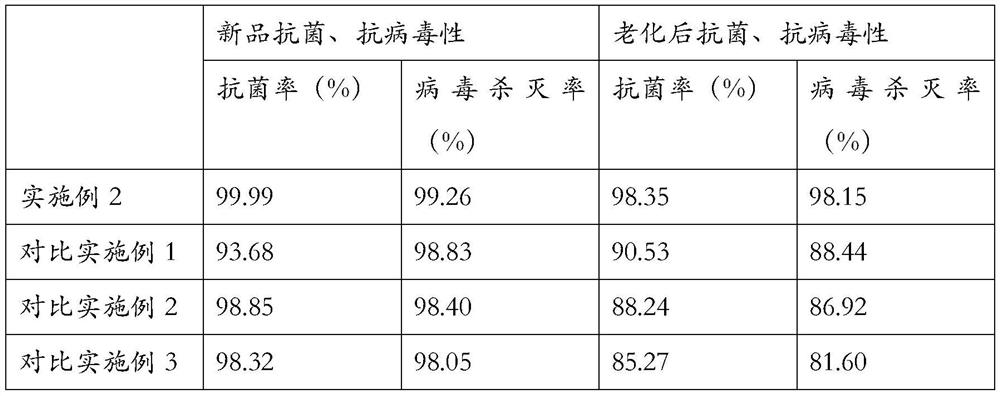

Embodiment 2

[0045] An antibacterial and antiviral coating, comprising the following substances in corresponding parts by weight:

[0046] 78 parts of film-forming resin, 13 parts of emulsion, 8 parts of film-forming aid, 1 part of defoamer, 0.8 part of wetting agent, 6 parts of modified filler, 3 parts of antibacterial additive, and 0.2 part of amine neutralizer.

[0047] The film-forming resin is styrene-acrylic resin; the emulsion is paraffin wax emulsion; and the film-forming aids are n-butanol and propylene glycol.

[0048] The preparation method of modified filler is as follows:

[0049] 1) put the kaolin into the calciner for calcining treatment, and take it out after 1.3h;

[0050] 2) Carry out graded grinding treatment to the kaolin treated in step 1), and grade the kaolin after the proportioning is completed for subsequent use;

[0051] 3) Immerse the graded kaolin obtained in step 2) into a silane coupling agent, filter out and dry to constant weight.

[0052] During the calc...

Embodiment 3

[0060] An antibacterial and antiviral coating, comprising the following substances in corresponding parts by weight:

[0061] 80 parts of film-forming resin, 15 parts of emulsion, 9 parts of film-forming aid, 1.5 parts of defoamer, 1 part of wetting agent, 8 parts of modified filler, 4 parts of antibacterial additive, 0.3 part of amine neutralizer.

[0062] The film-forming resin is water-based acrylic resin; the emulsion is paraffin wax emulsion; and the film-forming aids are n-butanol, propylene glycol and glycerin.

[0063] The preparation method of modified filler is as follows:

[0064] 1) put kaolin into the calciner for calcining treatment, and take it out after 1.5h;

[0065] 2) Carry out graded grinding treatment to the kaolin treated in step 1), and grade the kaolin after the proportioning is completed for subsequent use;

[0066] 3) Immerse the graded kaolin obtained in step 2) into a silane coupling agent, filter out and dry to constant weight.

[0067] During t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com