Preparation method of low-color-number tri(C8-10 alcohol) trimellitate

A technology for trimellitic acid tris and trimellitic anhydride is applied in the field of preparation of low-color trimellitic acid triesters, which can solve the problems of serious equipment corrosion, high impurities and high acid value, and achieve the effects of less waste water and less side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

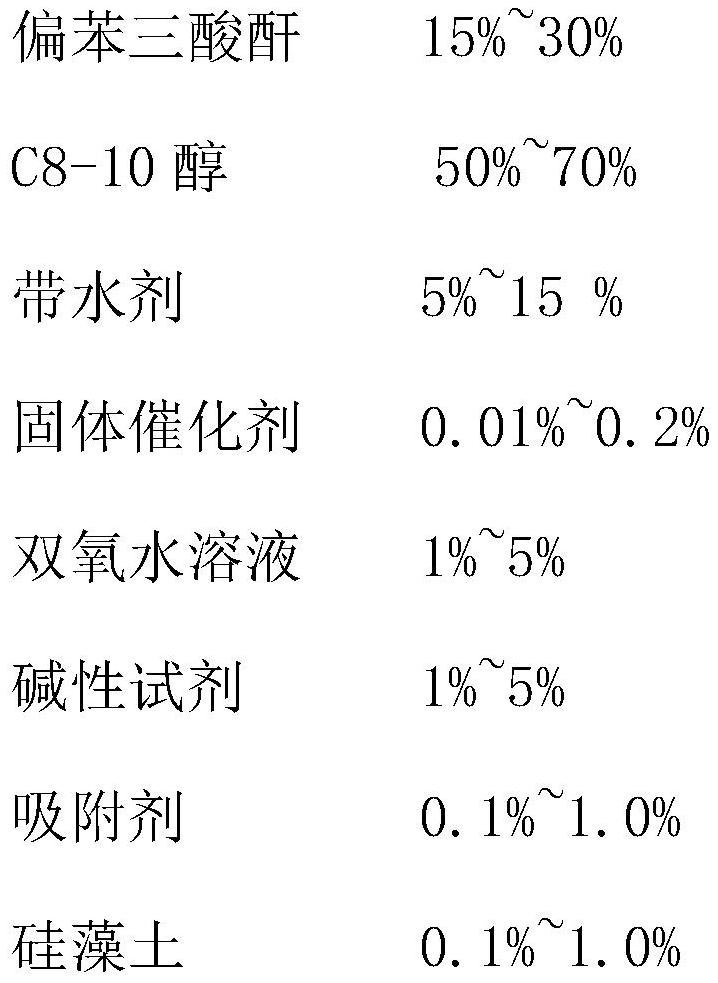

Method used

Image

Examples

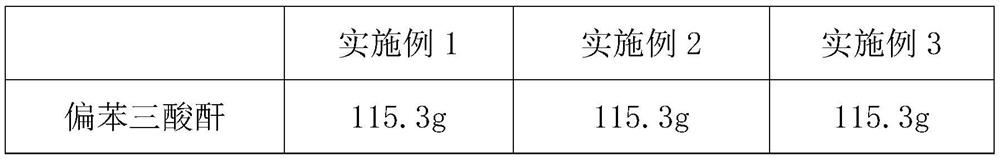

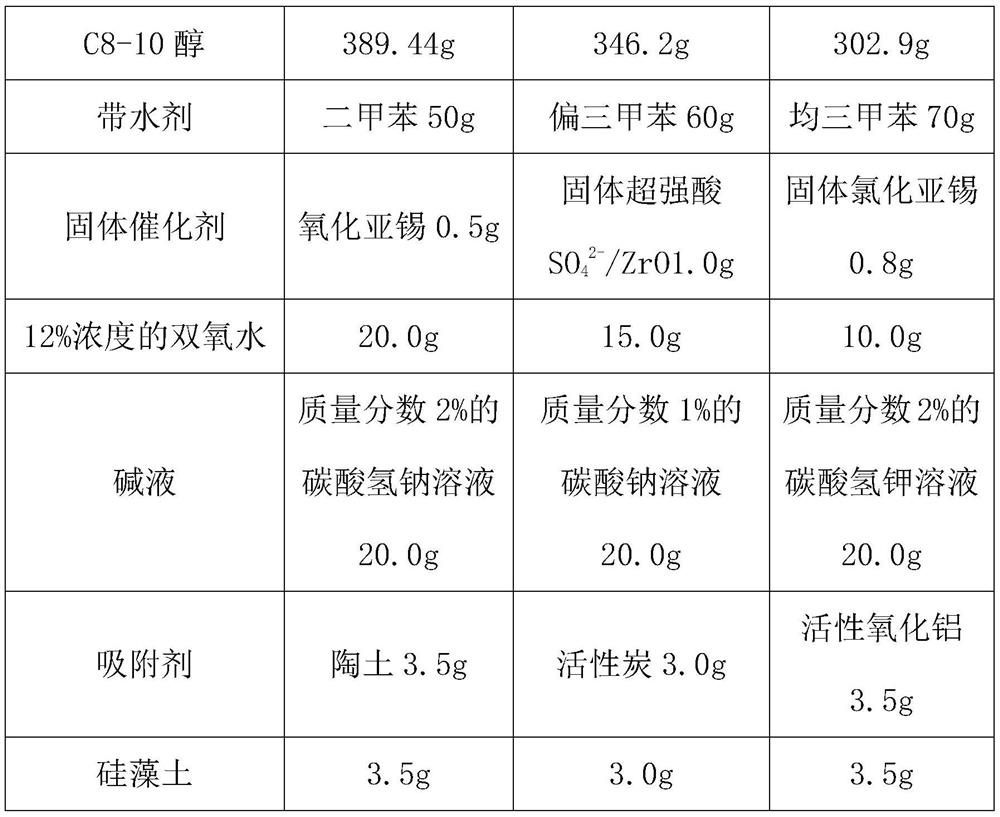

Embodiment 1

[0026] (1) Esterification: 115.3 g of raw material trimellitic anhydride and 389.44 g of C8-10 alcohol are dropped into the reaction kettle, put into under the protection of nitrogen, add 50 g of water-carrying agent xylene, heat up to 120 DEG C under stirring so that the solid trimellitic anhydride is completely dissolved, When the temperature was raised to 170°C, the reaction solution began to produce water, and after 30 minutes, 0.5g of stannous oxide was added, and finally the temperature was raised to 195°C, and the acid value of the reaction solution was measured to be 0.056mgKOH / g when the temperature was kept at 3h;

[0027] (2) Dealcoholization: Stop heating, turn on the vacuum, the vacuum degree is -0.095MPa, use the remaining temperature of the reaction solution to remove most of the excess C8-10 alcohol under stirring, and the vacuum time is 1h;

[0028] (3) Filtration: when the temperature of the above reaction solution is cooled to about 120°C, the solid catalyst ...

Embodiment 2

[0035] (1) Esterification: Put 115.3g of raw materials trimellitic anhydride and 346.2g of C8-10 alcohol into the reaction kettle, and put them into the reactor under the protection of nitrogen. Dissolve, the reaction solution starts to flow out at around 170°C, keep the solution for 60 minutes before adding solid super acid SO 4 2- / ZrO 1.0g, and finally raised the temperature to 200°C, and when the timer was started for 4 hours, the acid value of the reaction solution was measured to be 0.045mgKOH / g;

[0036] (2) Dealcoholization: stop heating, turn on the vacuum, the vacuum degree is -0.095MPa, use the remaining temperature of the reaction solution to remove most of the excess C8-10 alcohol under stirring, and the vacuum time is 0.5h;

[0037] (3) Filtration: when the temperature of the above reaction solution is cooled to about 120°C, the solid catalyst is recovered by filtration while it is hot;

[0038] (4) Oxidation: Add 15.0 g of pre-prepared 12% hydrogen peroxide to...

Embodiment 3

[0044](1) Esterification: Put 115.3g of raw materials trimellitic anhydride and 302.9g of C8-10 alcohol into the reaction kettle, put them into the reactor under nitrogen protection, add 70g of water-carrying mesitylene, heat up to about 120°C under stirring to make the solid trimellitic anhydride completely Dissolve, and the reaction liquid starts to flow out at around 170°C, keep the liquid out for 45 minutes, then add 0.8g of solid stannous chloride, and finally raise the temperature to 205°C, start timing and keep warm for 3.5h, the acid value of the reaction liquid is measured as 0.062mgKOH / g;

[0045] (2) Dealcoholization: stop heating, turn on the vacuum, the vacuum degree is -0.095MPa, use the remaining temperature of the reaction solution to remove most of the excess C8-10 alcohol under stirring, and the vacuum time is 0.5h;

[0046] (3) Filtration: when the temperature of the above reaction solution is cooled to about 120°C, the solid catalyst is recovered by filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com