A device for ultrasonically cracking municipal sludge to reduce sludge moisture content

A municipal sludge and water content technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of further reduction of sludge, limited work, bad smell, etc. problems, to avoid physical and chemical treatment processes, improve processing speed, and accelerate the cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

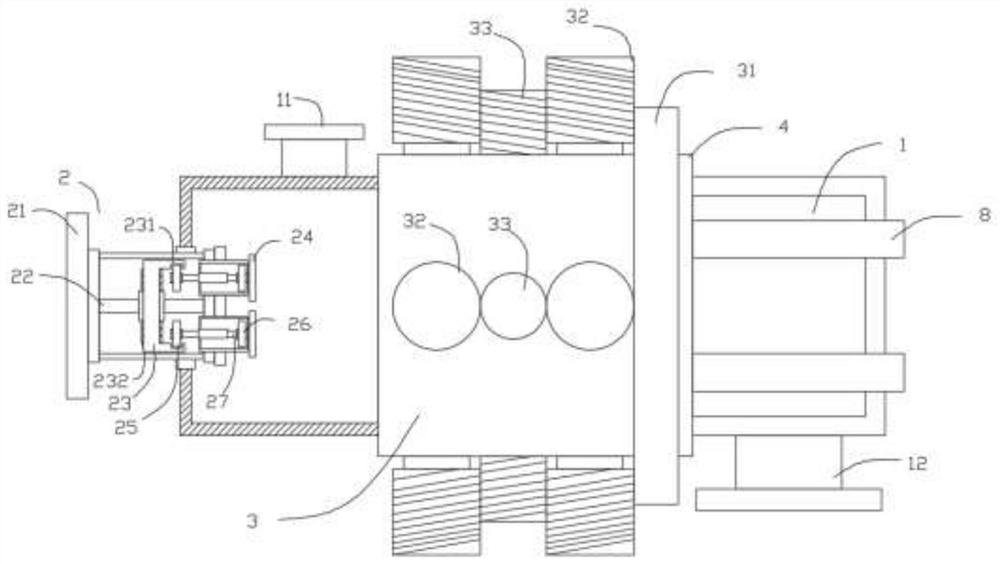

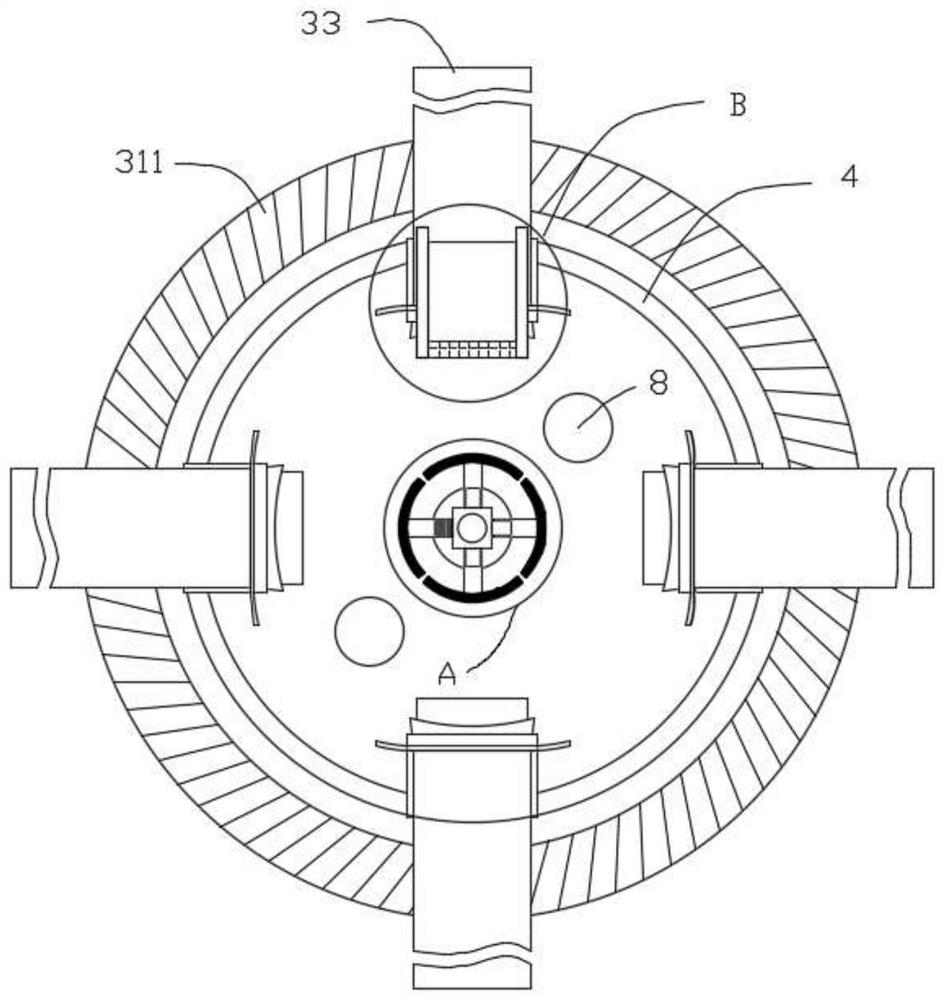

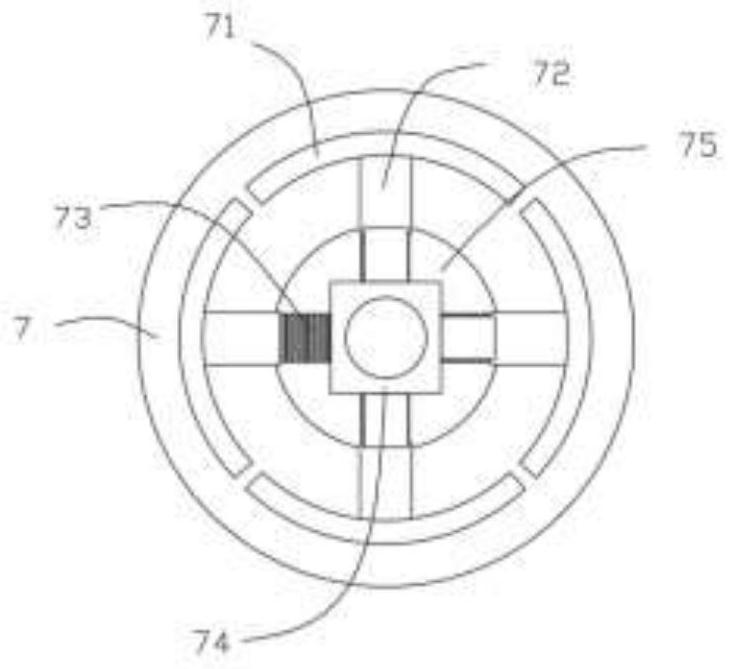

[0029] Such as figure 1 and figure 2 As shown, an equipment for ultrasonically cracking municipal sludge to reduce the water content of sludge mainly includes: a treatment tank 1 for sludge treatment, a treatment mechanism 3 arranged on the treatment tank 1, a treatment mechanism 3 arranged on the treatment tank The buffer mechanism 7 in 1, two magnetic stirring rotors 8 are set in the processing mechanism 3;

[0030] The treatment tank 1 comprises: a mud inlet 11 and a mud outlet 12, a microbubble generating mechanism 2 is arranged at the position of the mud inlet 11;

[0031] Such as figure 1 As shown, the microbubble generating mechanism 2 includes: a gas inlet 21 for connecting to an external gas supply device, a plurality of gas outlet pipes 24 located at the opposite end of the gas inlet 21, arranged in each of the gas outlet pipes 24 The cutting disk 26 used for gas cutting, the driven wheel 25 for driving the cutting disk 26, the first rotating shaft 22 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com