Ultrasonic combined with modified eggshell method to crack excess sludge

A technology of excess sludge and ultrasonic wave, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of high operating cost and long cracking time, and achieve the effect of saving the cost of chemicals, reducing the cracking time and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

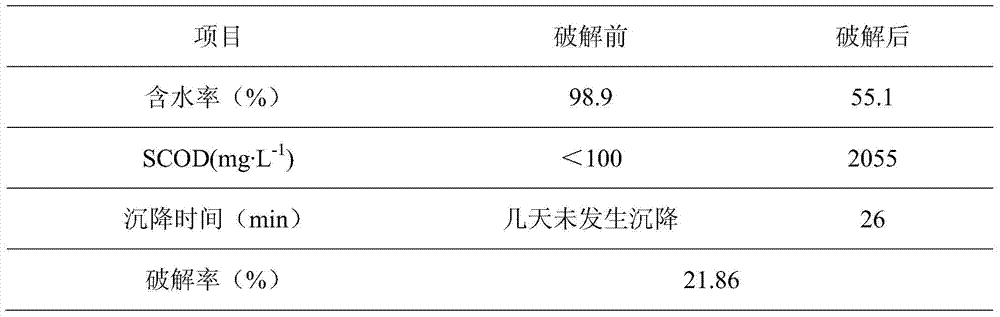

Embodiment 1

[0026] (1) Sampling of egg shells and excess sludge:

[0027] The eggshells are taken from the dining garbage in the student canteen, and the remaining sludge is taken from the sludge in the secondary sedimentation tank of the sewage treatment plant. The eggshells are cleaned with deionized water to clean the surface. Store at a constant temperature of 4°C until use.

[0028] (2) Preparation of modified eggshell cracking agent:

[0029] Wash the eggshell with deionized water to remove the dirt on the surface, dry it at 100°C, and then use a pulverizer to crush the dried eggshell and pass it through a 1mm sieve; soak the eggshell powder in 4mol / L potassium hydroxide In the solution for 0.5h, filter to remove water, roast at 700°C for 1 hour, and then pulverize to obtain powder A, soak powder A in 2.5mol / L sulfuric acid solution for 0.5h; centrifuge to remove the upper layer, collect the lower layer of solids and wash with water , and then calcining the washed solid at 700°C f...

Embodiment 2

[0047] (1) Sampling of eggshells and excess sludge is the same as in Example 1.

[0048] (2) Preparation of modified eggshell cracking agent:

[0049] Wash the eggshell with deionized water to remove the dirt on the surface, dry it at 100°C, and then use a pulverizer to crush the dried eggshell and pass it through a 1.25mm sieve; soak the eggshell powder in 4mol / L hydroxide Potassium solution for 1 hour, filtered to remove moisture, roasted at 750°C for 2 hours, and then pulverized to obtain powder A. Soak powder A in 2.5mol / L sulfuric acid solution for 1 hour; centrifuge to remove the upper layer, collect the lower layer of solids and wash with water. Then the washed solid was calcined at 750°C for 2 hours, cooled, ground into a powder with a particle size below 2mm, and set aside;

[0050] (3) cracking reaction:

[0051] According to adding 0.1g of modified eggshells per milliliter of excess sludge, take 20mL of excess sludge, add modified eggshells to it, put it in a 50mL...

Embodiment 3

[0057] (1) Sampling of eggshells and excess sludge is the same as in Example 1.

[0058] (2) Preparation of modified eggshell cracking agent:

[0059] Wash the eggshells with deionized water to remove the dirt on the surface, dry them at 100°C, then crush the dried eggshells with a pulverizer and pass through a 1.43mm sieve; soak the eggshell powder in 4mol / L hydroxide Potassium solution for 1.5h, filtered to remove moisture, roasted at 800°C for 3 hours, and then pulverized to obtain powder A. Soak powder A in 2.5mol / L sulfuric acid solution for 1.5h; centrifuge to remove the upper layer, collect the lower layer of solid Washing with water, then calcining the washed solid at 800°C for 3 hours, cooling, grinding into a powder with a particle size below 2mm, and setting aside;

[0060] (3) cracking reaction:

[0061] According to adding 0.2g of modified eggshells per milliliter of excess sludge, take 20mL of excess sludge, add modified eggshells to it, put it into a 50mL reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com