Full-quantitative treatment method of kitchen biogas slurry

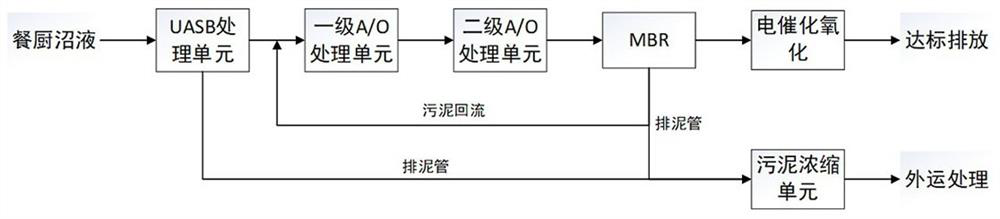

A technology for quantitative treatment and biogas slurry, which is applied in the field of fully quantitative treatment of kitchen biogas slurry, can solve the problems of difficult treatment, high organic content, and high salinity in membrane concentrate, so as to enhance removal efficiency, improve solid-liquid separation efficiency, and achieve The effect of full quantization processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

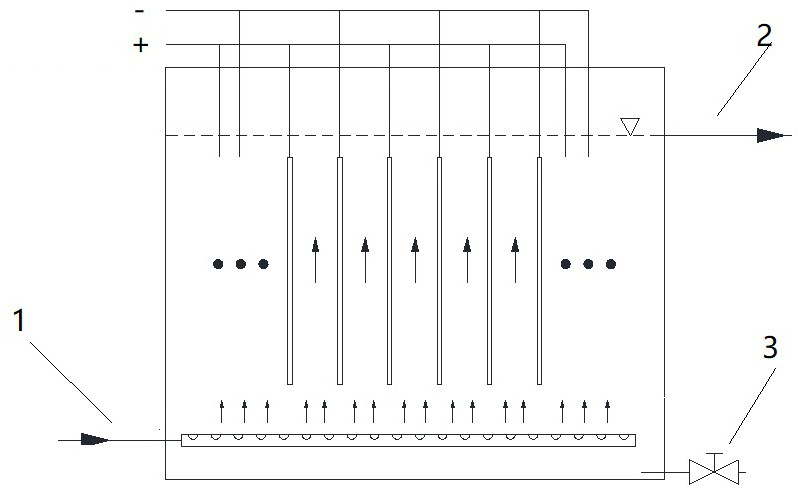

Method used

Image

Examples

Embodiment 1

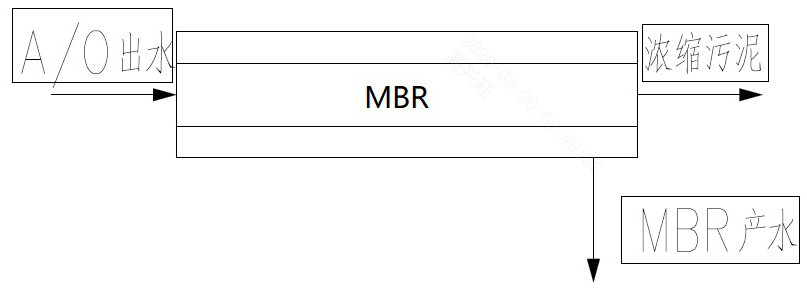

[0049] Using the method of the present invention to treat the biogas slurry wastewater of a certain kitchen collection and transportation center, COD: 40000~50000mg / L, TDS: <10000mg / L, TN: <1800mg / L, NH3-N: <500mg / L, pH Value: 6~9. This waste water passes through the UASB system, and the UASB volume load is 5kgCOD / (m3d), so that 80% of the COD in the kitchen wastewater is removed, and the COD in the effluent of the UASB system is reduced to 8000~10000mg / L. In the first-level A / O process, the return flow of the mixed liquid from the first-level O pool to the first-level A pool is controlled at 400%, and the first-level A / O system is used to remove 75% of COD and 85% of ammonia nitrogen in the system. The COD in the effluent of the primary A / O system is 2000~2500mg / L, and the ammonia nitrogen content is less than 90mg / L. The first-level A / O produced water flows into the second-level A / O treatment system, and the return flow from the second-level O pool to the second-level A poo...

Embodiment 2

[0051] Using the method of the present invention to treat a venous industrial park kitchen waste water, COD: 40000~45000mg / L, TDS: <9000mg / L, TN:<2000mg / L, NH3-N:<600mg / L, pH value: 6~9 . After the kitchen wastewater is anaerobically treated, the COD in the wastewater is reduced to 8000~9000mg / L; the anaerobic effluent flows into the A / O system by itself, and in the first-level A / O system, the reflux ratio of the nitrifying liquid is controlled at 300%, and the COD is removed The ammonia nitrogen removal rate is 70%, the ammonia nitrogen removal rate is 85%, the COD in the effluent of the primary A / O system is 1200~1350mg / L, and the ammonia nitrogen is <90mg / L; The removal rate is 30%, the ammonia nitrogen removal rate is 50%, the COD after the secondary A / O process is 840~945mg / L, and the ammonia nitrogen is <45mg / L. The effluent from the secondary A / O system enters the MBR treatment system to achieve sufficient mud-water separation. The water from the MBR system enters the...

Embodiment 3

[0053] Using the method of the present invention to treat a venous industrial park kitchen waste water, COD: 45000~50000mg / L, TDS: <10000mg / L, TN:<1500mg / L, NH3-N:<400mg / L, pH value: 4~8 . After three-phase degreasing, the kitchen waste water enters the UASB anaerobic treatment system, the COD in the waste water is reduced to 9000~10000 mg / L, and the COD removal is above 80%; the anaerobic effluent is sent to the first-level A / O treatment system to further remove the waste water Ammonia nitrogen and organic matter in the wastewater, after the first-level A / O treatment, the COD in the wastewater is reduced to 1300mg / L~1500mg / L, and the ammonia nitrogen is reduced to 50~70mg / L; the effluent of the first-level A / O system enters the second-level A / O system Outlet water, further remove COD, ammonia nitrogen, and total nitrogen in the wastewater, and reduce the COD in the effluent of the secondary A / O system to 800mg / L~1000mg / L, the ammonia nitrogen to 30~50mg / L, and the total nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com