A preparation method of palladium-cellulose membrane capable of simultaneous emulsion separation and dye degradation

A cellulose membrane and emulsion separation technology, applied in chemical instruments and methods, semi-permeable membrane separation, membranes, etc., can solve problems such as poor oil-water emulsion separation performance, easy aggregation of palladium nanoparticles, and rapid decline in membrane flux. To achieve the effect of abundant reserves, easy recycling and increased recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

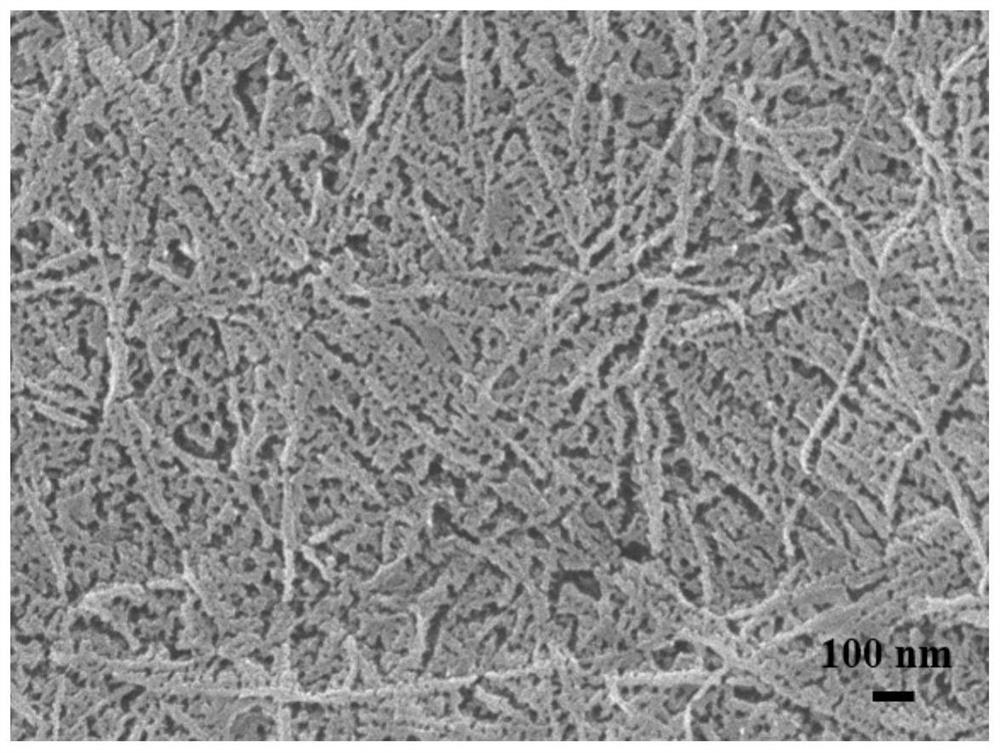

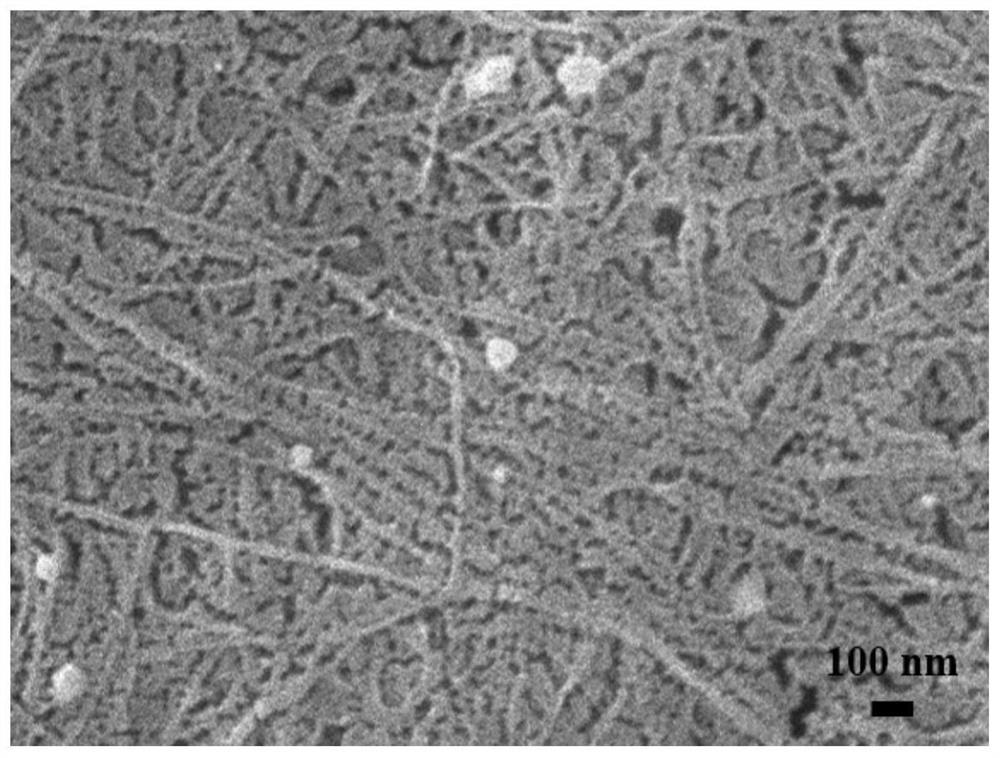

[0028] Specific embodiment one: a kind of preparation method of the palladium-cellulose membrane that can synchronize emulsion separation and dyestuff degradation in this embodiment, it is carried out according to the following steps:

[0029] 1. Preparation of cellulose membrane:

[0030] sandwiching the support membrane in the separation device, then pouring the cellulose dispersion with a mass percentage of 0.5% to 2% onto the support membrane of the separation device, and suction filtering to obtain the cellulose membrane;

[0031] 2. Loaded palladium particles:

[0032] immersing the cellulose membrane in an aqueous palladium source solution, heating at a temperature of 45°C to 65°C for 5h to 6h, to obtain a cellulose membrane loaded with palladium particles;

[0033] The mass percentage of the palladium source in the palladium source aqueous solution is 0.01% to 0.1%;

[0034] 3. Drying:

[0035] The cellulose membrane loaded with palladium particles is dried to compl...

specific Embodiment approach 2

[0047] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the supporting membrane described in step 1 is a PVDF membrane. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the palladium source aqueous solution described in step two is palladium chloride aqueous solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com