Stamping forming method for small-caliber and deep-cavity cap-shaped part

A stamping forming, deep cavity technology, applied in the field of sheet metal parts forming, hat bearing stamping, stamping and forming of aluminum alloy plate parts, can solve the complex structure of liquid-filled mold, the limited liquid-filled forming process, The wall thickness of parts is out of tolerance and other problems, so as to reduce the cost of trial and error, realize mechanized forming, and reduce the difficulty of processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

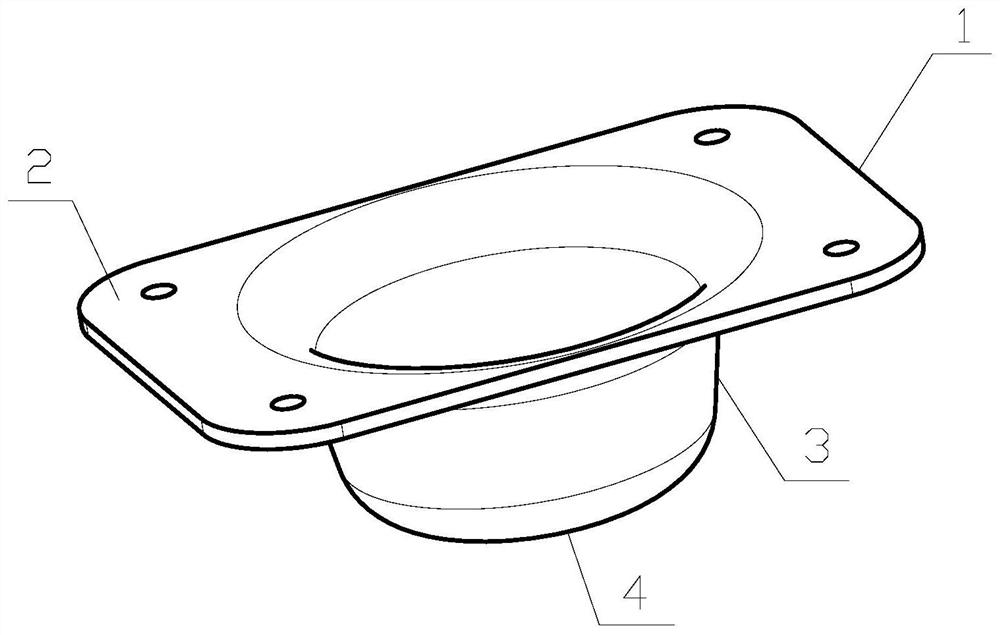

[0039] Referring to the drawings, the aircraft parts provided by the examples are figure 1 As shown, the part is a small diameter, a deep cavity mount 1, mainly consisting of three major parts, including strip along the flange 2, the barrel side wall 3, and the cap type bottom 4. The diameter of the cap shaped bottom 4 and the strip of the flange 2 are close to 1: 3, and the cap-type support 1 once in the range of 0.38 ~ 0.42, the maximum problem with the prior art formation is the side wall 3 and the bottom 4 The phase is not formed in place, premature breakage.

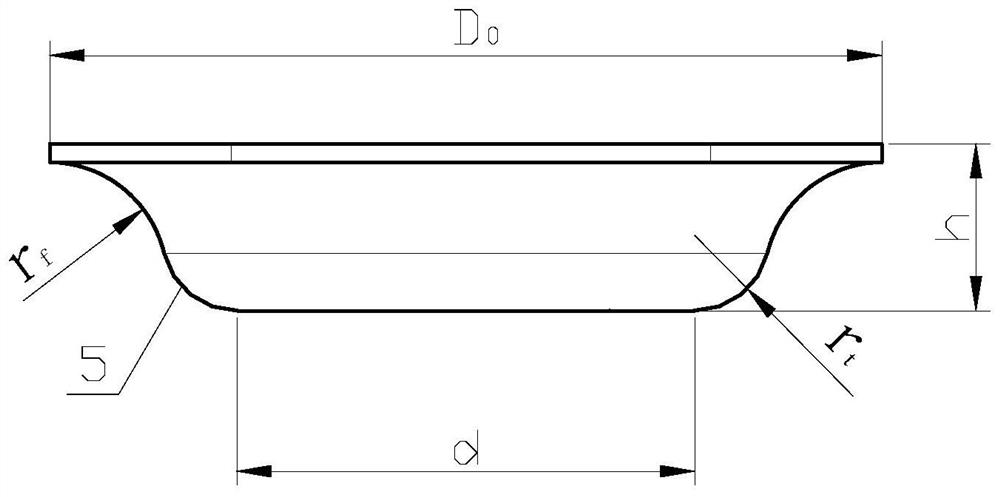

[0040] Such as Figure 2-7 As shown, a small diameter, a stamped forming method of a deep cavity support, comprising the steps of:

[0041] Step 1: Construct a transition punch

[0042] The structure of the cap shaped support is a matrix, and a transition stamper 9 having a diameter is increased, and the depth of the cavity is lowered and the side wall has a constant inclination. Figure 2-5 Indicated.

[0043] Step 1-1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com