Shell cleaning device for decorative material production

A decorative material and cleaning device technology, applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., can solve the problems that affect the efficiency of shell processing, long time for cleaning mud and sand, and small specific gravity. Achieve the effects of avoiding the accumulation of shells, improving the conveying effect, and increasing the number of contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

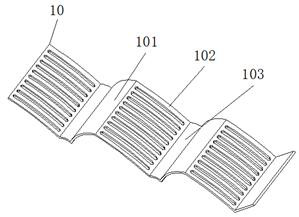

[0027] refer to Figure 1-5 , a shell cleaning device for decorative material production, comprising a box body 1, a feed hopper 8 and a discharge hopper 14 are fixedly installed on the top of the box body 1, and a bucket elevator 15 is fixedly installed inside the discharge hopper 14, and the box The bottom of the body 1 is fixedly installed with a filter 18 and a circulating pump 2 communicating with each other, and the inlet end of the filter 18 is connected with the box body 1, and the outlet end of the circulating pump 2 is fixedly installed with a three-way valve 6, and the inside of the box body 1 is fixed. A plurality of rectangular tubes 5 are installed, and a grate mechanism 16 is fixedly installed between the end of the rectangular tube 5 and the bottom wall of the casing 1, and a plurality of spray heads 13 are fixedly installed on the top of the rectangular tube 5, and the rectangular tube 5 The pipe communicates with the three-way valve 6, and a plurality of rota...

Embodiment 2

[0037] refer to Figure 1-5 , a shell cleaning device for the production of decorative materials. Compared with Embodiment 1 in this embodiment, a plurality of spoilers 20 are fixedly installed on the outside of the rotating shaft 17, and the spoilers 20 are distributed in a staggered manner inside the rectangular tube 5. The spoiler 20 is located below the spray head 13 .

[0038] When this embodiment is in use, when the rotating shaft 17 rotates, the spoiler 20 is driven to rotate, and when the spoiler 20 rotates to the upper position, the hole at the connection part between the rectangular tube 5 and the spray head 13 is blocked. Affect the spray water pressure of the water column of the spray head 13, and then generate multiple areas with different flow velocities inside the box 1, driving the shells to continuously change positions and collide with each other, and improve the cleaning quality of the internal sediment by increasing the shell movement , to further improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com