Methoxylamine mother liquor double-effect evaporation device and method in furan ammonium salt production

A technology of methoxyamine parent and furan ammonium salt, which is applied in the field of double-effect evaporation device for methoxyamine mother liquid in the production of furan ammonium salt, which can solve the problems of high labor intensity, slow evaporation speed, poor heat transfer effect, etc., and achieve reduction Effect of labor cost, improvement of production efficiency and improvement of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

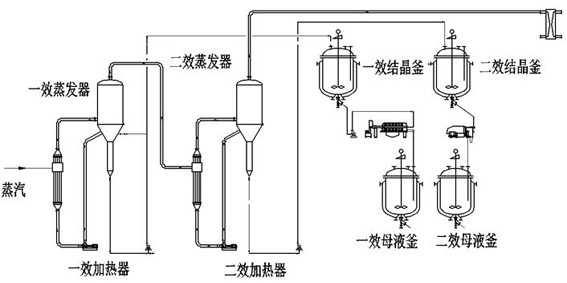

Image

Examples

Embodiment 1

[0025] (1) at 1m 3 Pump the rectified methoxyamine mother liquor to the shell side of the first-effect evaporator heater at the amount of / h, control the temperature of the heater at 45°C, and enter the first-effect evaporator after the methoxyamine mother liquor is preheated. After the solution volume in the effect evaporator reaches 2000L, stop adding the methoxyamine mother liquor; 3 Pump the distilled methoxyamine mother liquor to the shell side of the second-effect evaporator heater at the amount of / h, control the temperature of the heater at 45°C, and enter the second-effect evaporator after the methoxyamine mother liquor is preheated. After the amount of solution in the effect evaporator reaches 2000 L, stop adding the methoxyamine mother liquor;

[0026] (2) Control the pressure in the first-effect evaporator and the second-effect evaporator to be -0.08Mpa, use 1.5Mpa steam with a temperature of 300°C to heat the first-effect evaporator, and use the circulating pump ...

Embodiment 2

[0040] (1) at 0.9m 3 The amount of / h pumps the rectified methoxyamine mother liquor to the shell side of the first-effect evaporator heater, controls the temperature of the heater at 42 °C, and the methoxyamine mother liquor enters the first-effect evaporator after being preheated, and waits for a After the amount of solution in the effect evaporator reaches 2000 L, stop adding the methoxyamine mother liquor; 3 Pump the distilled methoxyamine mother liquor to the shell side of the second-effect evaporator heater at the amount of / h, control the temperature of the heater at 42°C, and enter the second-effect evaporator after the methoxyamine mother liquor is preheated. After the amount of solution in the effect evaporator reaches 2000 L, stop adding the methoxyamine mother liquor;

[0041] (2) Control the pressure in the first-effect evaporator and the second-effect evaporator to be -0.07Mpa, use 1.3Mpa steam with a temperature of 320°C to heat the first-effect evaporator, and...

Embodiment 3

[0046] (1) at 1.1m 3 Pump the rectified methoxyamine mother liquor into the shell side of the first-effect evaporator heater at the amount of / h, control the temperature of the heater at 50°C, and enter the first-effect evaporator after the methoxyamine mother liquor is preheated, and wait for one After the solution volume in the effect evaporator reaches 2000L, stop adding the methoxyamine mother liquor; 3 Pump the rectified methoxyamine mother liquor to the shell side of the second-effect evaporator heater at the amount of / h, control the temperature of the heater at 50°C, and enter the second-effect evaporator after the methoxyamine mother liquor is preheated. After the solution volume in the effect evaporator reaches 2000L, stop adding the methoxyamine mother liquor;

[0047] (2) Control the pressure in the first-effect evaporator and the second-effect evaporator to be -0.09Mpa, use 1.7Mpa steam with a temperature of 290°C to heat the first-effect evaporator, and use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com