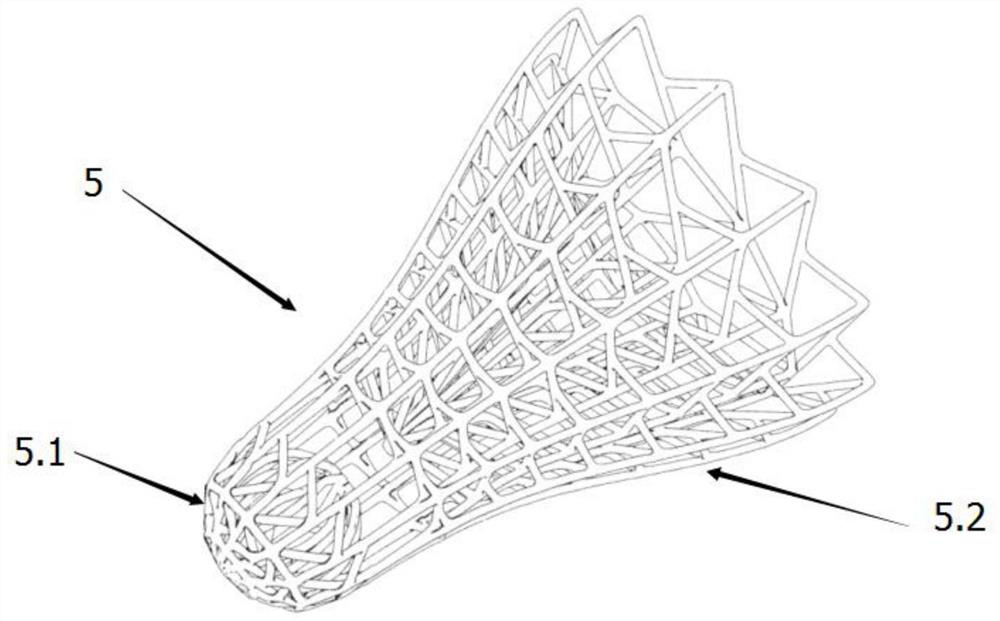

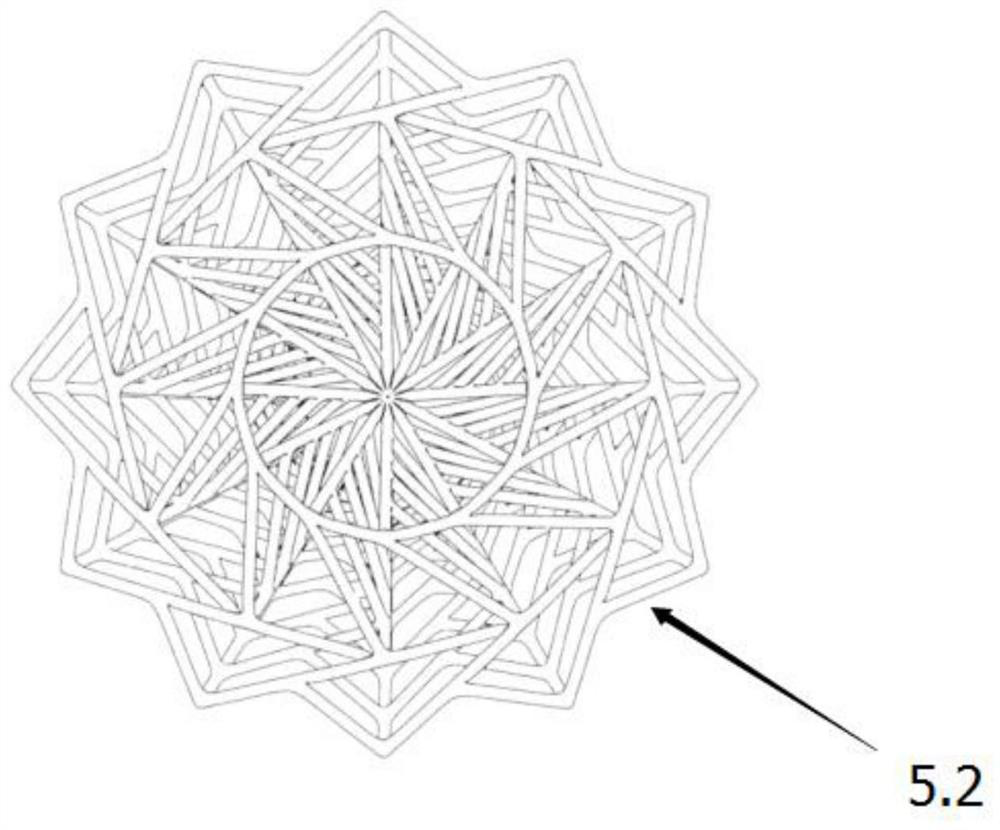

Shuttlecock with customizable structure and method for photocuring 3D printing of shuttlecock

A 3D printing and badminton technology, applied in the field of additive manufacturing, can solve the problems of flight trajectory changes, low durability, and the ball skirt is difficult to approach natural feathers, etc., to achieve the effect of stable flight trajectory and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

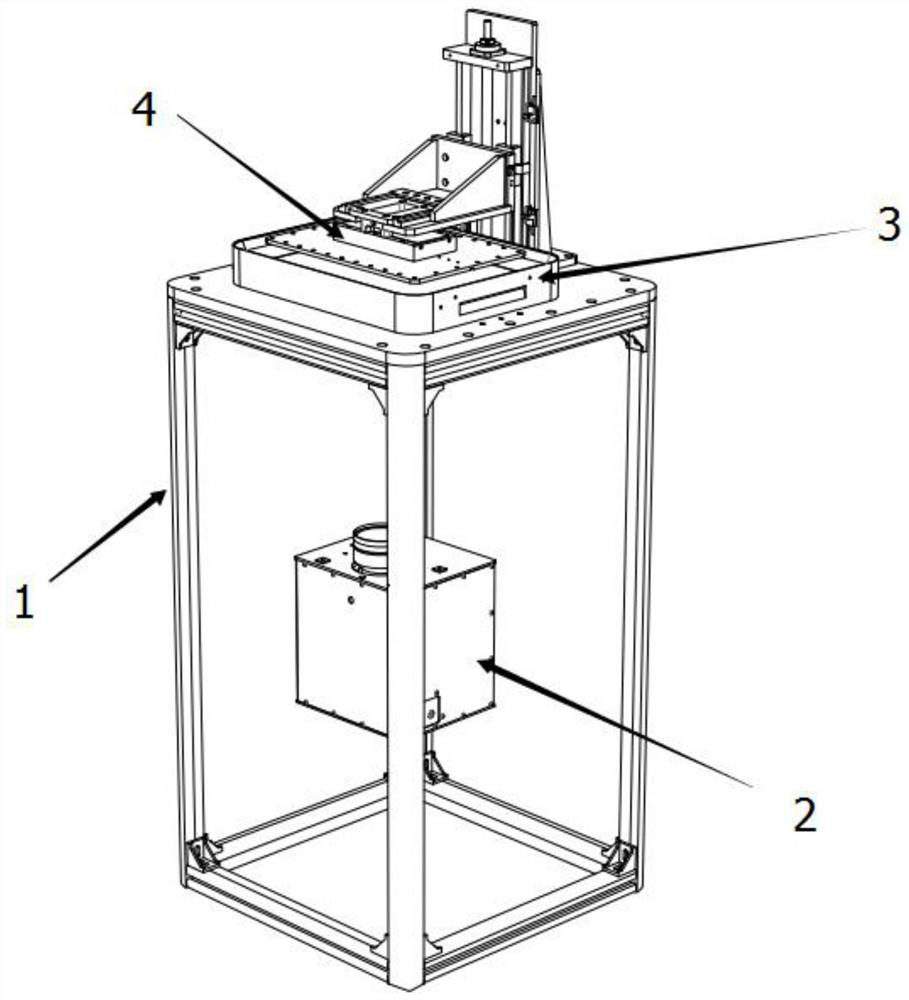

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be further described in detail below in conjunction with specific embodiments.

[0032] It will be understood that when an element is referred to as being "on," "attached to," "connected to," "coupled" to, or "contacting" another element, another element When an element or the like is present, it may be directly on, attached to, connected to, bonded to, and / or in contact with another element or intervening elements may also be present. In contrast, when an element is referred to as being "directly on," "directly attached to," "directly connected to," "directly coupled to" or "directly in contact with" another element When another element is used, there are no intermediate elements. Those skilled in the art will also appreciate that a reference to a structure or element being disposed "adjacent" to another element may have portions that overlie or underlie the adjacent element.

[0033] Spatially relative terms such as "below", "below", "lower", "abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com