Optical system design method based on combination of TIR and micro-lens array

A microlens array and optical system technology, applied in optics, optical components, instruments, etc., can solve the problems of few microlens arrays and lack of complete design of free-form surface microlenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

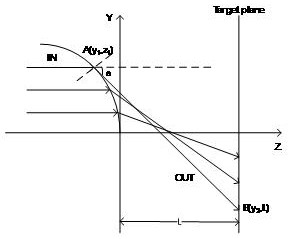

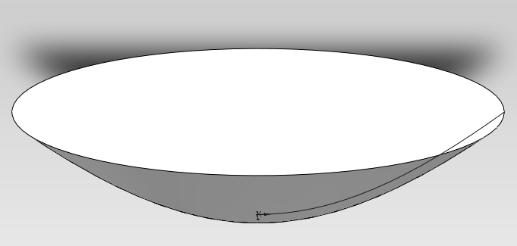

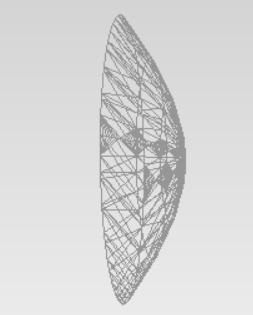

[0046] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the specific situation of the optical path of the free-form surface microlens of the present invention is introduced. When the light emitted from the LED light source passes through the TIR lens, all the light becomes parallel to the optical axis, and the parallel light will be redistributed through the microlens array again, and finally evenly distributed on the target plane. The shape of the free-form surface microlens is determined by the following scheme:

[0047] In this embodiment, a Cartesian coordinate system is established based on the cross-section passing through the central axis of rotation of the free-form surface microlens as the reference plane. The central axis of rotation is the Z axis, and the direction passing through the origin of the coordinate system and perpendicular to the central axis i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com