Device and method for guiding fiber coating precursor coating through laser irradiation

A technology of laser irradiation and precursors, which is applied in the field of fiber manufacturing, can solve problems such as insufficient binding force, easy falling off, and easy adhesion, and achieve the effects of low cost, ensuring uniformity and maturity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

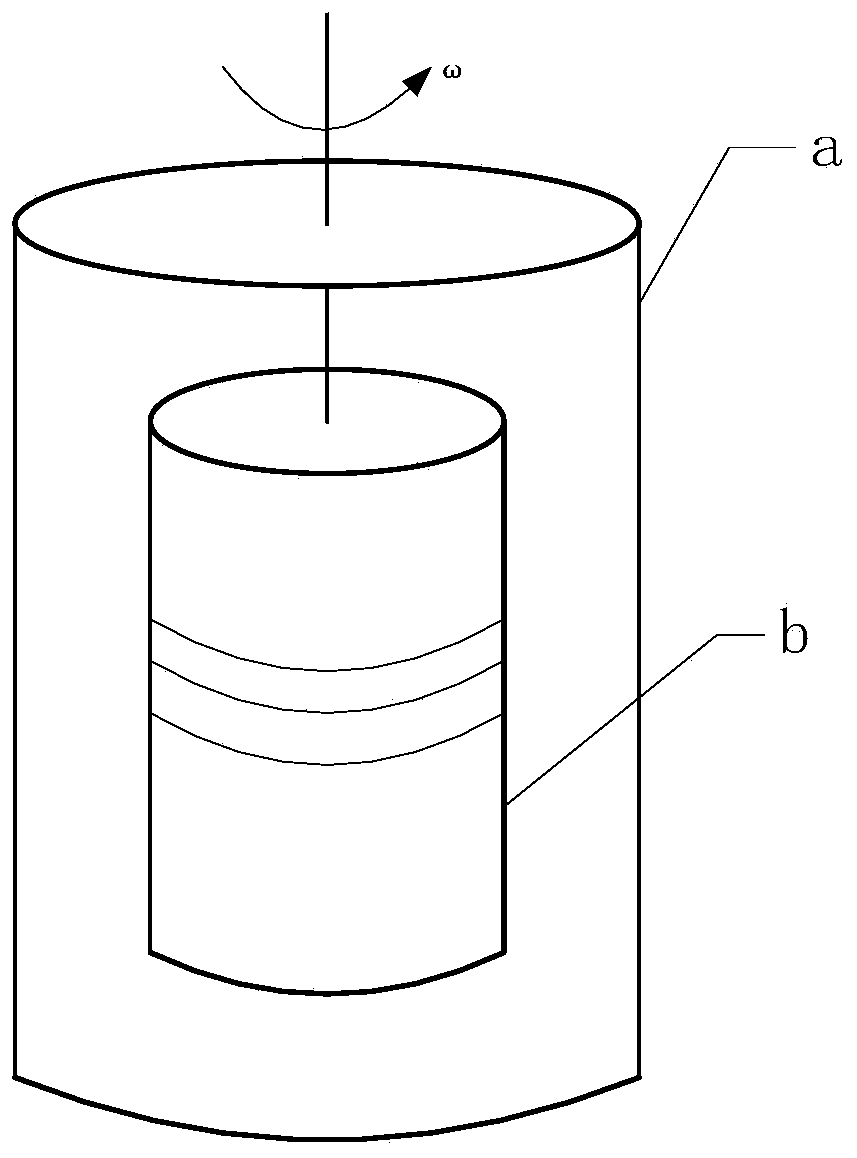

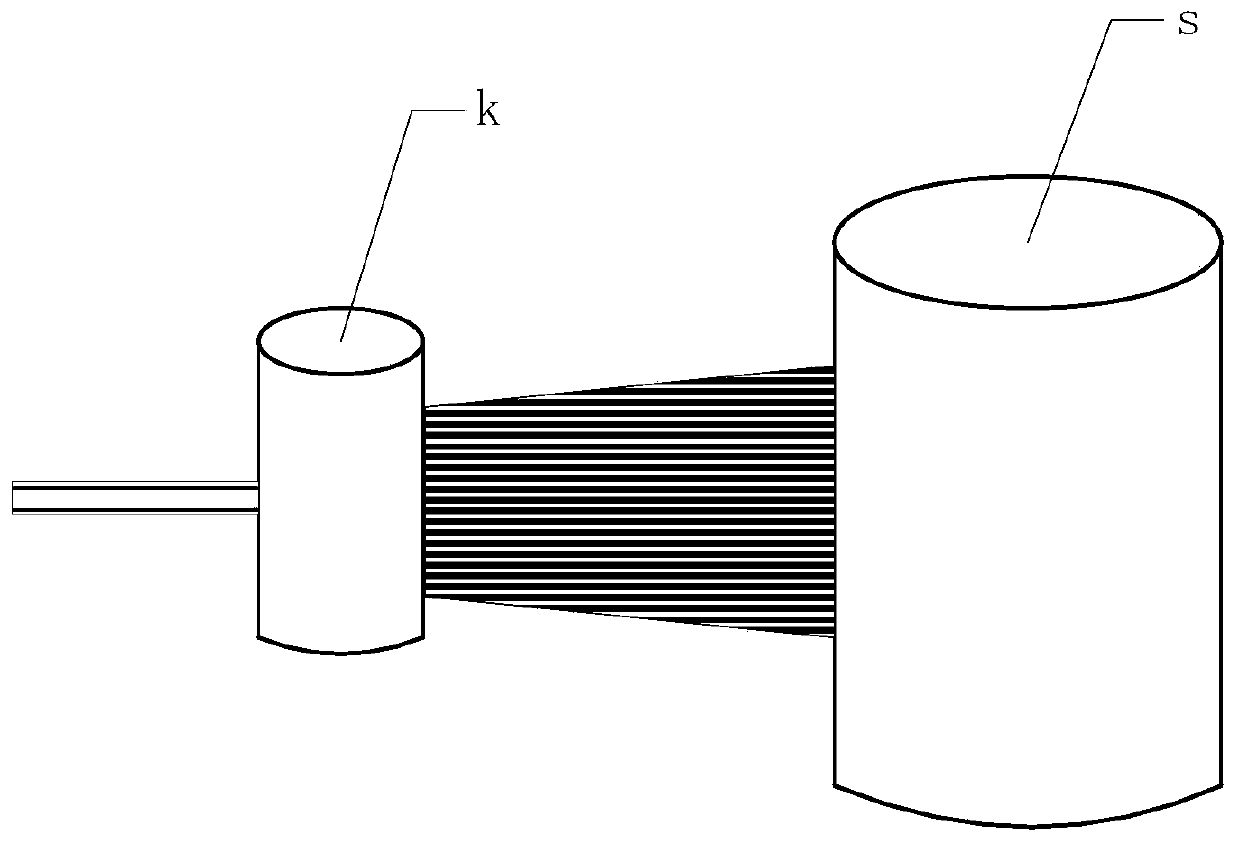

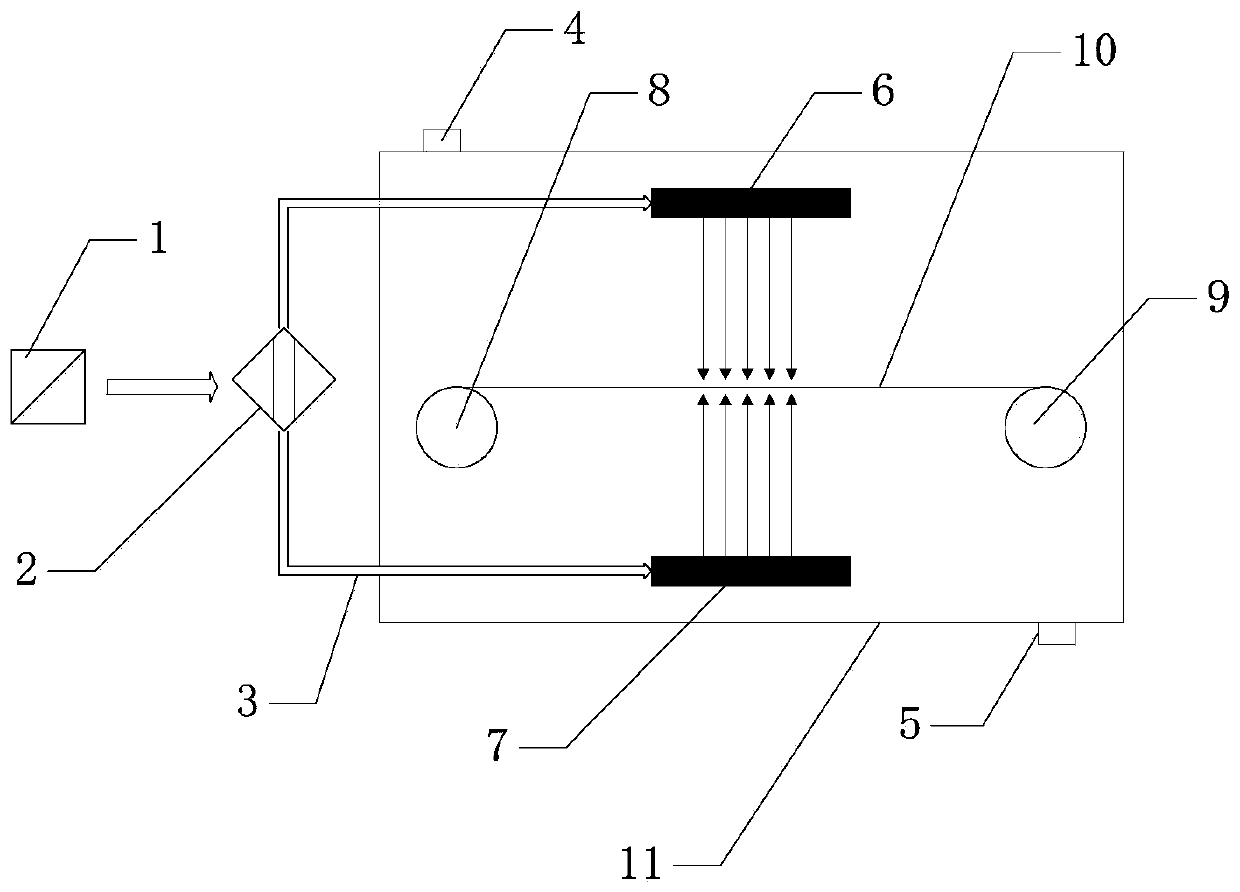

[0046] The selected fiber is carbon fiber, and the coating precursor solution is a silicon carbide precursor solution with a concentration of 35%. The selected carbon fiber is completely immersed in the silicon carbide precursor solution. Then take out the impregnated carbon fiber and evenly wind it on the centrifugal drum of the desizing device. Adjust the rotating speed of the centrifugal drum to 800r / min, and desizing until there is no adhesion silicon carbide precursor solution between the fibers. Take out the fiber that has been desized, add it to the beam expanding device, expand the fiber bundle to a single layer of fiber of 10 cm, and evenly wind it on the fiber collecting drum. Put the fiber collection tube with the pretreated fibers on the conveyor roller in the closed chamber, and pass nitrogen with a temperature of 15°C as the protective gas from the air inlet of the closed chamber. Select the laser wavelength to be 355nm and the output power to be 10W.

[0047] Ad...

Embodiment 2

[0049] The selected fiber is silicon carbide fiber, and the coating precursor solution is an alumina precursor solution with a concentration of 60%. The selected silicon carbide fibers are completely immersed in the alumina precursor solution. Then take out the impregnated silicon carbide fiber and evenly wind it on the centrifugal drum of the desizing device.

[0050] Adjust the rotating speed of the centrifugal drum to 1200r / min, and desizing until there is no longer any adhesion alumina precursor solution between the fibers. Take out the fiber after desizing, add it to the beam expanding device, expand the fiber bundle to 50cm single layer fiber, and evenly wind it on the fiber collecting drum. Put the fiber collection tube with the pretreated fibers on the conveyor roller in the closed chamber, and pass carbon dioxide with a temperature of 25°C as the protective gas from the air inlet of the closed chamber. Choose the laser wavelength as 10.6um, and the output power is 70W....

Embodiment 3

[0052] The selected fiber is alumina fiber, and the coating precursor solution is a silicon carbide precursor solution with a concentration of 80%. The selected silicon carbide fibers are completely immersed in the alumina precursor solution. Then take out the impregnated alumina fiber and evenly wind it on the centrifugal drum of the desizing device.

[0053] Adjust the rotating speed of the centrifugal drum to 1500r / min, and desizing until there is no adhesion silicon carbide precursor solution between the fibers. Take out the fiber after desizing, add it to the beam expanding device, expand the fiber bundle to 20cm single layer fiber, and evenly wind it on the fiber collecting drum. Put the fiber collection tube with the pretreated fibers on the conveyor roller in the closed chamber, and pass argon gas with a temperature of 50° C. as the protective gas from the air inlet of the closed chamber. The laser wavelength is selected as 1064nm and the output power is 60W. Adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com