Application method of a support mortar coagulant prepared from coal gangue

A bearing mortar and application method technology, applied in the field of building materials, can solve the problems of poor fluidity, high cost, insufficient early strength, etc., and achieve the effects of convenient construction, low cost, and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0027] Consists of the following number of parts by weight:

[0028] The industrial solid waste coal gangue is put into the crusher for crushing, and the particle size of the gangue after treatment is about 5 to 20mm, and then the crushed gangue is dry ground to obtain a particle size of 100 to 500 μm of gangue powder, and then the resulting gangue powder, water, and zirconia are compared to the mass ratio m 1:m 2 :m 3 =1:5:8, 0.03 parts of surface passivator, add wet grinding equipment for 40~60min, and obtain gangue slurry with a particle size of less than 0.3μm.

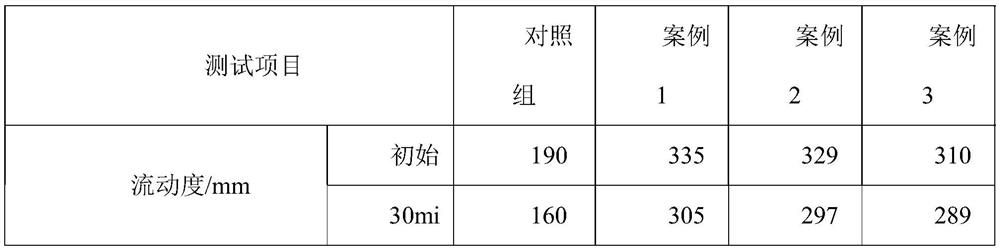

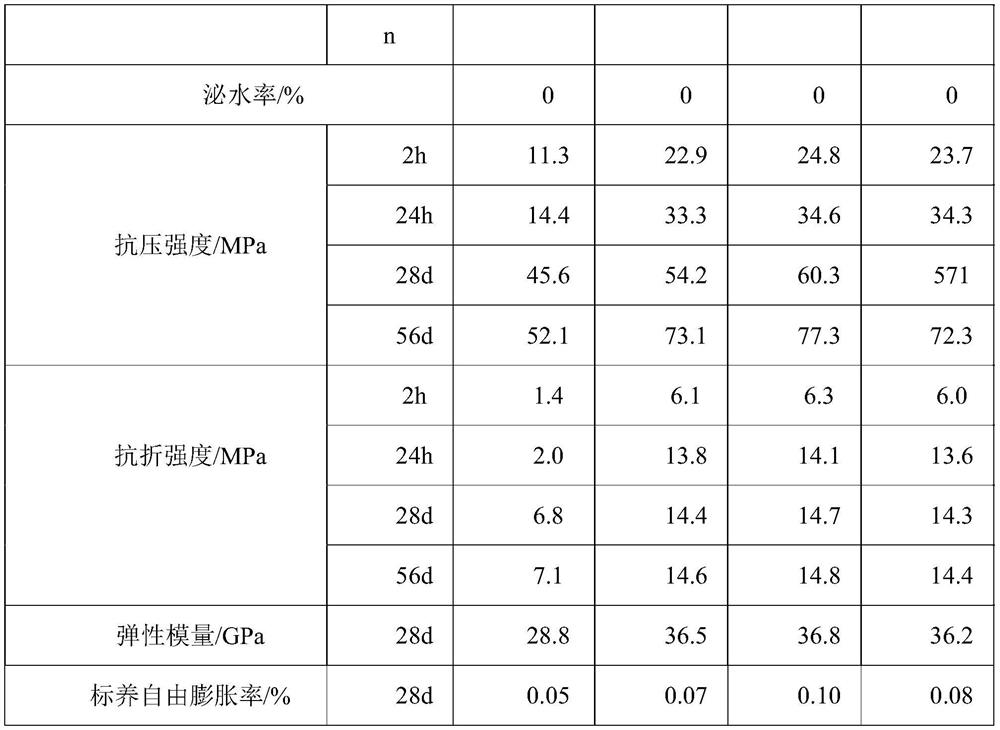

[0029] The preparation of the support mortar is as follows by weight: 39 parts of ordinary Portland cement, 6 parts of gangue coagulant, 20 parts of 30-40 mesh quartz sand, 30 parts of 40-50 mesh quartz sand, 0.2 parts of polycarboxylic acid high-efficiency superplasticizer, 4.55 parts of UEA expander, 0.15 parts of organic silicic acid defoamer, and 0.1 part of polypropylene fiber. The materials with good ratio are s...

Embodiment example 2

[0031] The industrial solid waste coal gangue is put into the crusher for crushing, and the particle size of the gangue after treatment is about 5 to 20mm, and then the crushed gangue is dry ground to obtain a particle size of 100 to 500 μm of gangue powder, and then the resulting gangue powder, water, and zirconia are compared to the mass ratio m 1 :m 2 :m 3 =1:5:8, 0.03 parts of surface passivator, add wet grinding equipment for 40~60min, and obtain gangue slurry with a particle size of less than 0.3μm.

[0032] The preparation of the support mortar by weight is as follows: 43 parts of ordinary Portland cement, 2 parts of coal gangue coagulant, 15 parts of 30-40 mesh quartz sand, 35 parts of 40-50 mesh quartz sand, 0.25 parts of polycarboxylic acid high-efficiency superplasticizer, 4.45 parts of UEA expander, 0.17 parts of organic silicic acid defoamer, 0.13 parts of polypropylene fiber. The mixed material is mixed and molded, and the strength of the test is shown in Table 1.

Embodiment example 3

[0034] The industrial solid waste coal gangue is put into the crusher for crushing, and the particle size of the gangue after treatment is about 5 to 20mm, and then the crushed gangue is dry ground to obtain a particle size of 100 to 500 μm of gangue powder, and then the resulting gangue powder, water, and zirconia are compared to the mass ratio m 1 :m 2 :m 3 =1:5:8, 0.03 parts of surface passivator, add wet grinding equipment for 40~60min, and obtain gangue slurry with a particle size of less than 0.3μm.

[0035]The preparation of the support mortar is as follows by weight: 35 parts of ordinary Portland cement, 10 parts of coal gangue coagulant, 15 parts of 30-40 mesh quartz sand, 35 parts of 40-50 mesh quartz sand, 0.15 parts of polycarboxylic acid high-efficiency superplasticizer, 4.50 parts of UEA expander, 0.25 parts of organic silicic acid defoamer, 0.1 part of polypropylene fiber. The mixed material is mixed and molded, and the strength of the test is shown in Table 1.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com