Phosphorus-modified ZSM-5 molecular sieve and preparation method thereof

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of destroying the molecular sieve skeleton structure and decreasing the crystallinity of molecular sieves, so as to reduce energy consumption and time, and effectively Facilitate the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

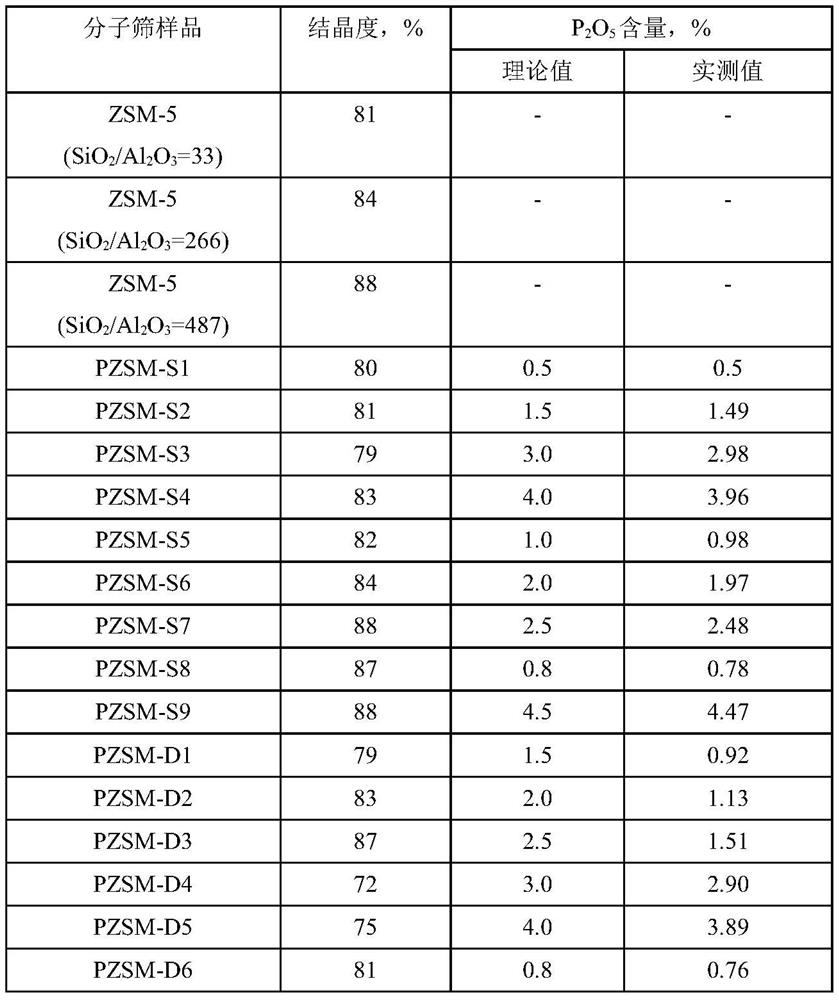

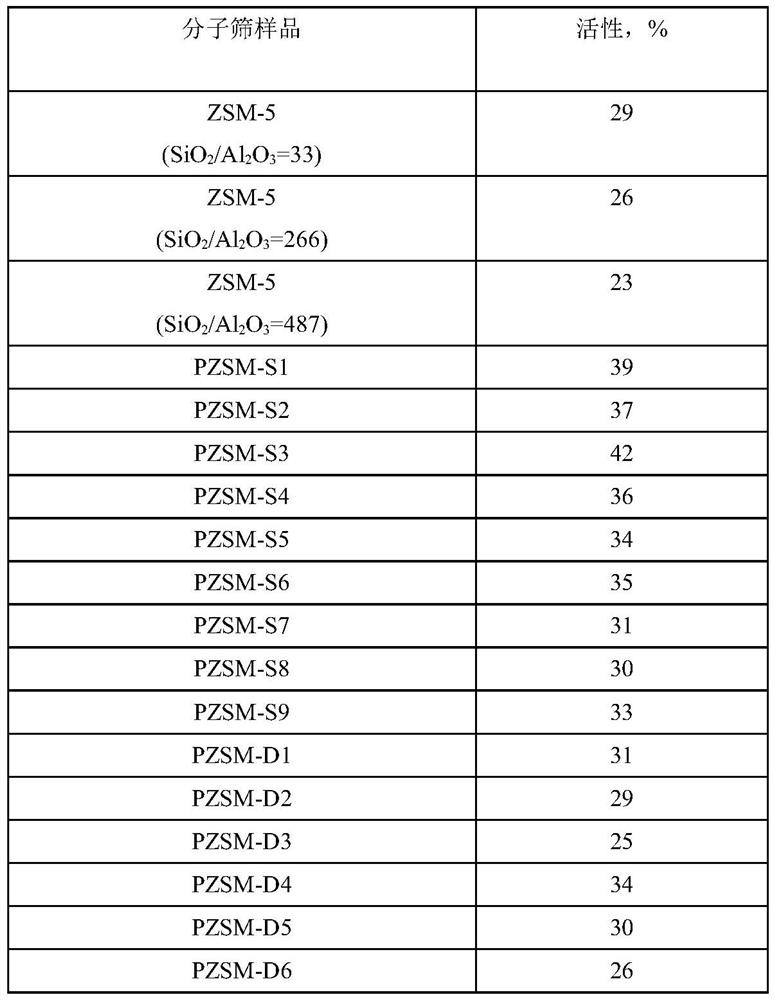

Embodiment 1

[0025] The method of the invention prepares phosphorus-modified ZSM-5 molecular sieves.

[0026] With 480 grams of ZSM-5 molecular sieves (dry basis, SiO 2 / Al 2 o 3 = 33), 7.57 grams of tetrakis hydroxymethyl phosphorus chloride and 1200 grams of deionized water were mixed, beaten, heated to 60 ° C, continued stirring for 3 hours, then filtered, dried, and roasted at 500 ° C for 3 hours to obtain Phosphorus modified ZSM-5 molecular sieve PZSM-S1.

Embodiment 2

[0028] The method of the invention prepares phosphorus-modified ZSM-5 molecular sieves.

[0029] With 535 grams of ZSM-5 molecular sieves (dry basis, SiO 2 / Al 2 o 3 =33), 3.05 grams of tetrakis hydroxymethyl phosphorus sulfate and 2140 grams of deionized water were mixed and beaten, heated up to 70°C, kept stirring for 2 hours, then filtered, dried, and roasted for 4 hours at a temperature of 400°C to obtain phosphorus Modified ZSM-5 molecular sieve PZSM-S2.

Embodiment 3

[0031] The method of the invention prepares phosphorus-modified ZSM-5 molecular sieves.

[0032] With 615 grams of ZSM-5 molecular sieves (dry basis, SiO 2 / Al 2 o 3 =33), 29.2 grams of tetrakis hydroxymethyl phosphorus chloride, 35.3 grams of tetrakis hydroxymethyl phosphorus sulfate and 4920 grams of deionized water were mixed and beaten, and the temperature was raised to 90° C., and the stirring reaction was continued for 0.5 hour, then filtered, dried, and dried at 700 Calcining at ℃ for 1 hour to obtain phosphorus-modified ZSM-5 molecular sieve PZSM-S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com