A dfb laser working at high temperature and method for growing epitaxial structure

A DFB laser and epitaxial structure technology, which is applied to the structure of lasers, semiconductor lasers, and optical resonators, can solve the problems of laser power drop and achieve the effect of improving high temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

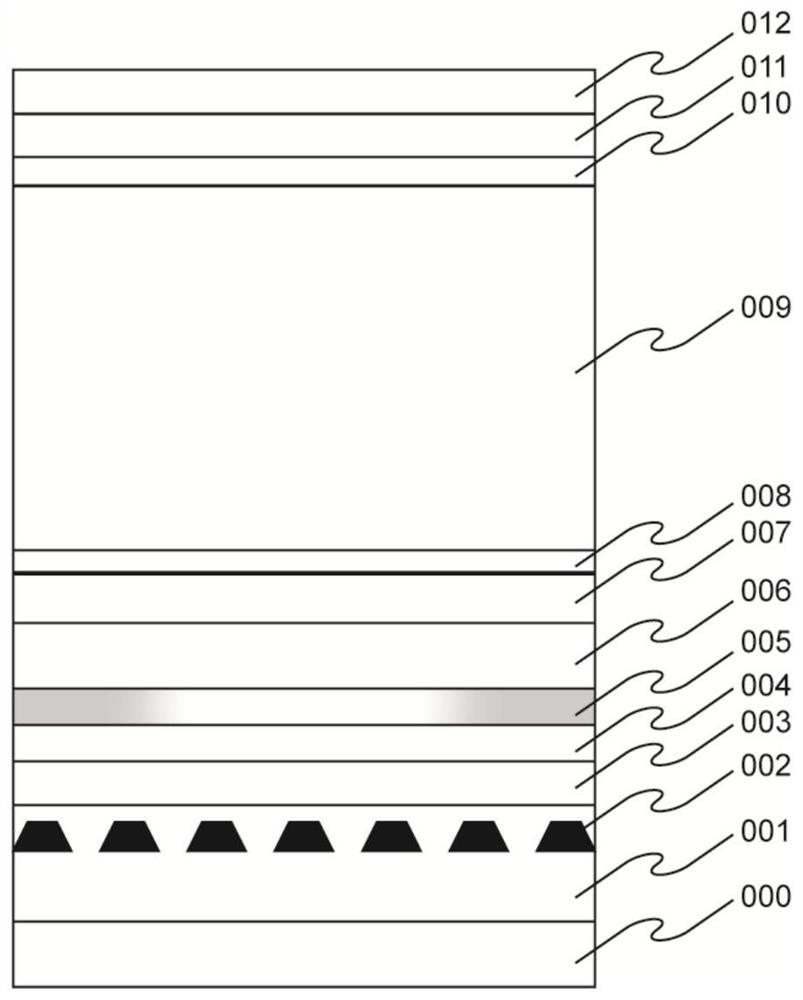

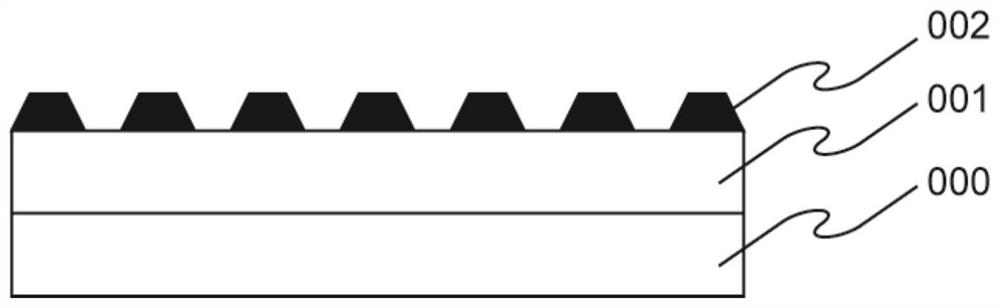

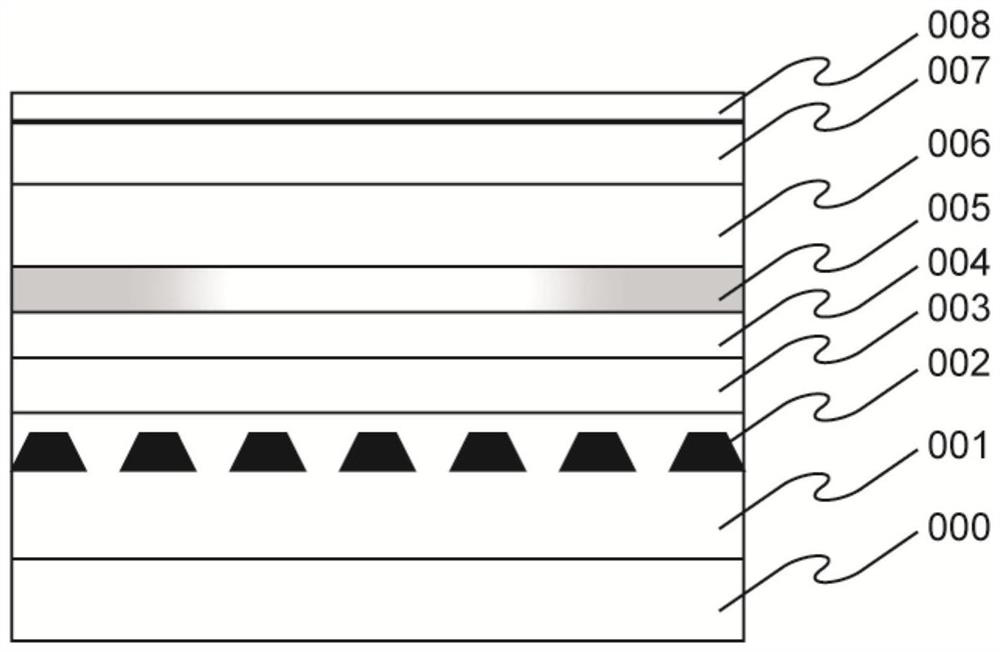

[0024] The embodiments of the present invention will be described below by specific embodiments, and those skilled in this specification can easily understand other advantages and efficacy of the present invention.

[0025] An example embodiment will now be described more fully with reference to the accompanying drawings. However, an example embodiment can be implemented in a variety of forms and is not to be construed as being limited to the examples set forth herein; in contrast, the present invention will make the present invention will be more comprehensive and complete, and the concept of example embodiments is fully conveyed A technician to those skilled in the art. The features, structures, or characteristics described may be incorporated in one or more embodiments in any suitable manner. In the following description, there is provided a number of specific details to give a sufficient understanding of the embodiments of the present invention. However, those skilled in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com