Collagen fiber quality judgment method

A collagen fiber and quality technology, applied in the field of judgment of collagen fiber quality, can solve problems such as time-consuming, inappropriate, complicated operation, etc., and achieve the effects of good guidance on production, scientific and reasonable design, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

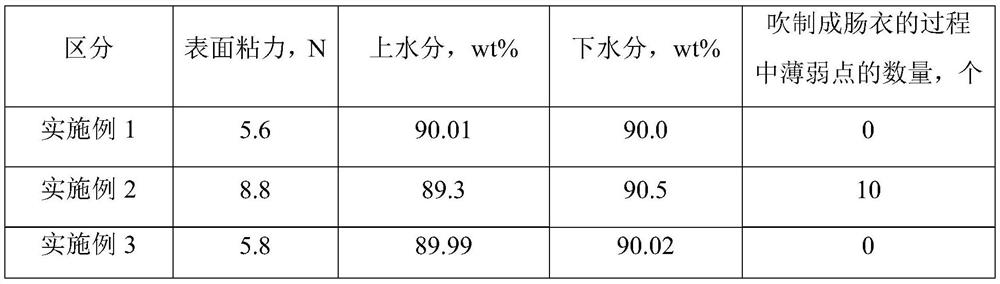

Embodiment 1

[0019] A method for judging the quality of collagen fibers, comprising the following steps:

[0020] Take the processed extracted collagen fibers (from the split skin of the yellow cowhide body), knead them evenly, first conduct moisture detection, and then calculate according to the results of the moisture detection, add ice water and mix the collagen fiber group Knead evenly, and the temperature of the material should not be higher than 18°C, so that the water mass content can reach 90%.

[0021] Put the collagen fiber group in a 50mL centrifuge tube and centrifuge in a high-speed centrifuge (10000rpm, 20min). Take out and measure the moisture of the upper end and the lower end, and there is no difference in the moisture content, indicating that the water is bound by the collagen fibers, and the fibers have strong water absorption.

[0022] Collagen fibrous mass surface viscosity detection: use a self-made device for detecting collagen surface viscosity (CN206594037U, autho...

Embodiment 2

[0024] A method for judging the quality of collagen fibers, comprising the following steps:

[0025] Take the processed extracted collagen fibers (from the split skin of the head of the yellow cowhide), knead them evenly, first conduct moisture detection, and then calculate according to the results of the moisture detection, add ice water and mix the collagen fiber group Knead evenly, and the temperature of the material should not be higher than 18°C, so that the water mass content can reach 90%.

[0026] Put the collagen fiber group in a 50mL centrifuge tube and centrifuge in a high-speed centrifuge (10000rpm, 20min). Take it out and measure the moisture of the upper and lower ends. If the moisture of the lower part is higher than that of the upper part, it means that the water absorption capacity is weak, the opening degree of the fiber bundles is not enough, or the collagen fibers are damaged during the hide treatment process, and the treatment is excessive.

[0027] Colla...

Embodiment 3

[0029] A method for judging the quality of collagen fibers, comprising the following steps:

[0030] Take the processed extracted collagen fibers (from the split skin of the head of the yellow cowhide), knead them evenly, first conduct moisture detection, and then calculate according to the results of the moisture detection, add ice water and mix the collagen fiber group Knead evenly, and the temperature of the material should not be higher than 18°C, so that the water mass content can reach 90%.

[0031] Put the collagen fiber group in a 50mL centrifuge tube and centrifuge in a high-speed centrifuge (10000rpm, 20min). Take out and measure the moisture of the upper end and the lower end, and there is no difference in the moisture content, indicating that the water is bound by the collagen fibers, and the fibers have strong water absorption.

[0032] Collagen fibrous mass surface viscosity detection: use a self-made device for detecting collagen surface viscosity (CN206594037U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com