Method for evaluating ultimate load borne by buried pipeline with defects

A limit load, pipeline technology, applied in the direction of using stable bending force to test material strength, using stable tension/pressure to test material strength, etc., can solve the problems of unknown and complex safety margins of oil and gas pipelines, and achieve elimination The effect of material mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

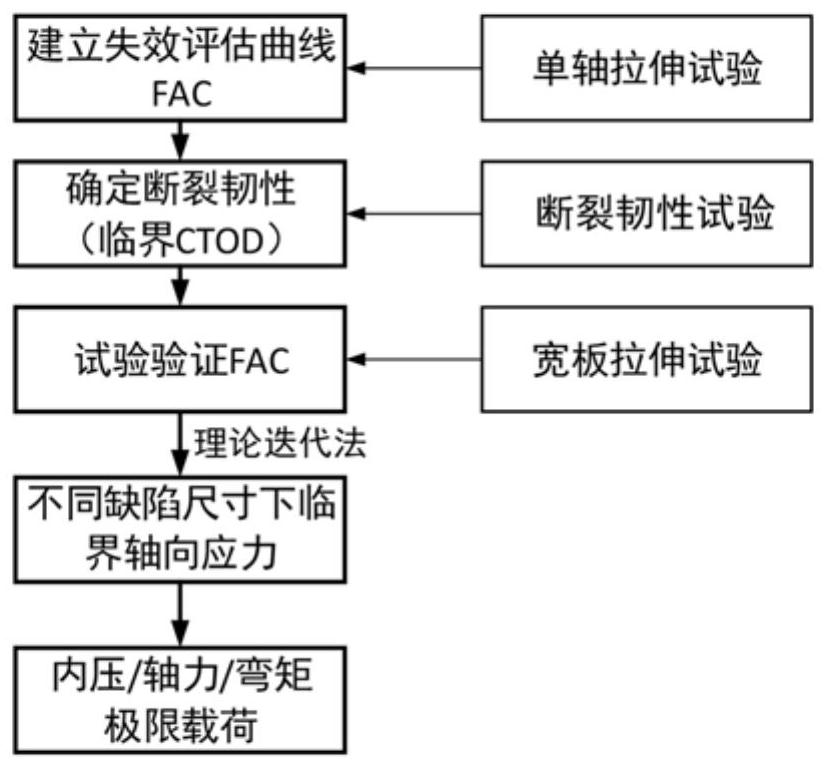

[0072] like figure 1 As shown, a method for evaluating the ultimate load of a buried pipeline with defects includes the following process:

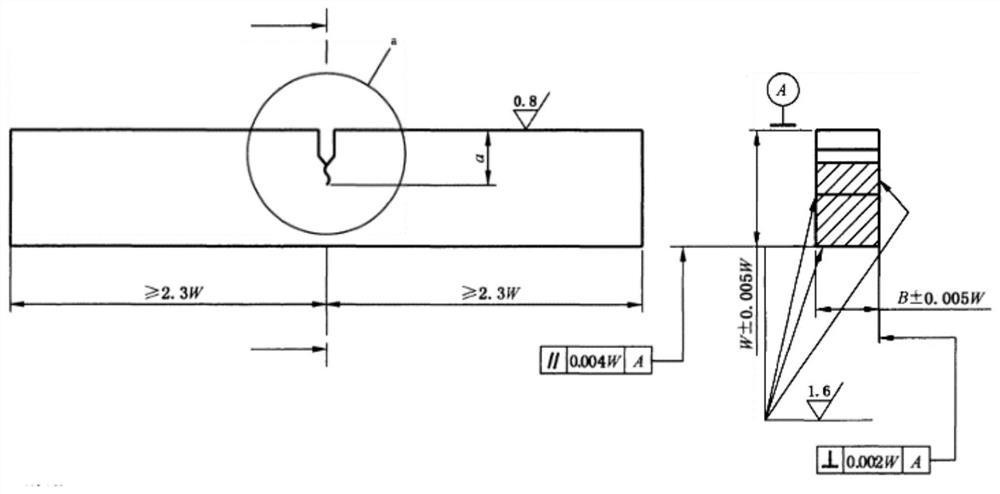

[0073] Step 1. Obtain the stress-strain curve through the uniaxial tensile test of the axial specimen of the pipeline (pipeline body and girth weld), and then obtain the yield strength σ according to the stress-strain curve y , elastic modulus E and ε ref , put σ y , E and ε ref Substituting it into the double criterion method of the failure assessment graph, the failure assessment curve of the pipeline is obtained. And the critical CTOD value of the pipeline is obtained through the unilateral notch tensile test.

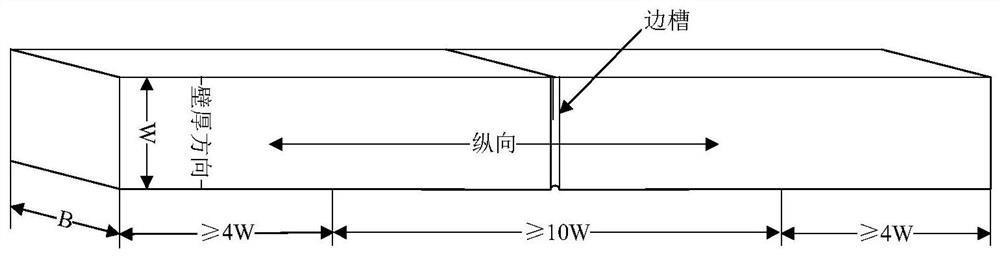

[0074] Step 2, design wide-plate tensile specimens, and conduct wide-plate tensile tests to verify the proposed failure evaluation curves.

[0075] Step 3, calculate the failure assessment point (Kr, Lr) method and verify the failure assessment curve to iteratively calculate the critical axial stress of the pipeline with d...

Embodiment 2

[0152] Create failure assessment curves

[0153] Cut the longitudinal sample of X70 material φ813mm×14.7mm pipe, and conduct longitudinal uniaxial tensile test. The tensile test engineering stress-strain curve is as follows: Figure 7 shown. Yield strength σ of X70 large deformation pipeline steel y It is 494MPa, and the tensile strength is 675MPa.

[0154] Take Lr=0.1, 0.3, 0.5, 0.7, 0.9, 0.95, 1.0, 1.05, 1.1, 1.2, then the corresponding engineering stress σ, true strain ε ref and Kr are shown in the table below;

[0155] Table 1 Failure evaluation curve solution parameter table

[0156] Lr σ ε ref

Kr 0.1 49.4 0.000235 0.997509 0.3 148.2 0.000706 0.978232 0.5 247 0.001176 0.942809 0.7 345.8 0.001647 0.896221 0.95 444.6 0.002117 0.843649 1.0 469.3 0.002235 0.830097 1.05 494 0.004352 0.686753 1.1 518.7 0.00653 0.592117 1.2 543.4 0.00878 0.529154

[0157] By fitting the curve with formula (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com