Feeding chamber for rotary kiln for calcining needle coke

A technology of feeding chamber and rotary kiln, which is applied in the direction of rotary drum furnace, lighting and heating equipment, descaling device, etc., to achieve the effect of reasonable and humanized operation, improved automation level, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

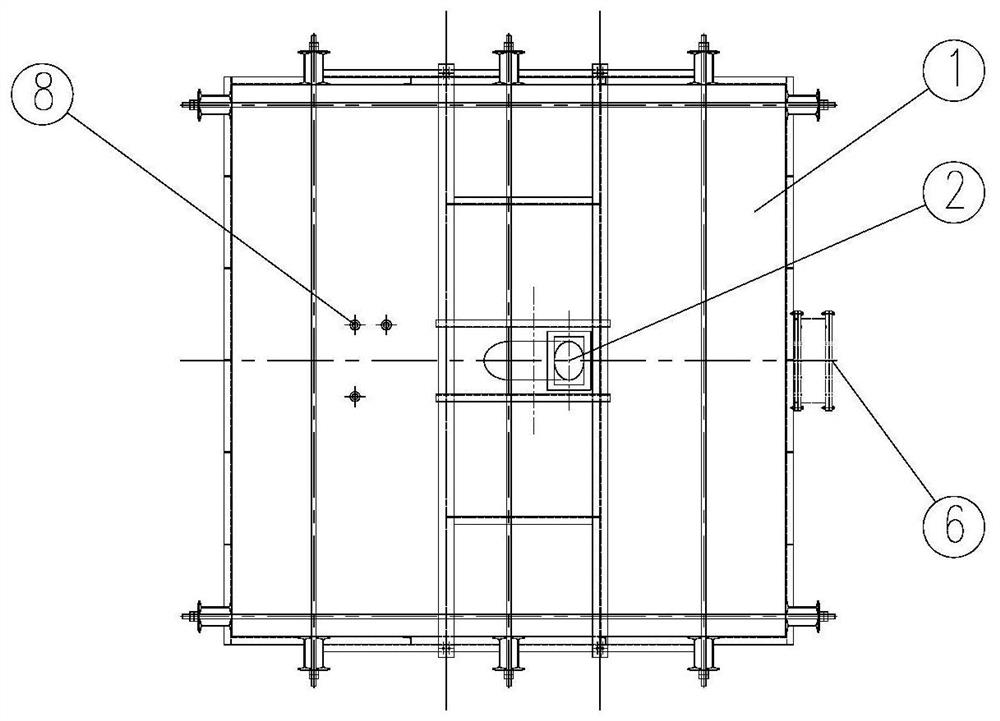

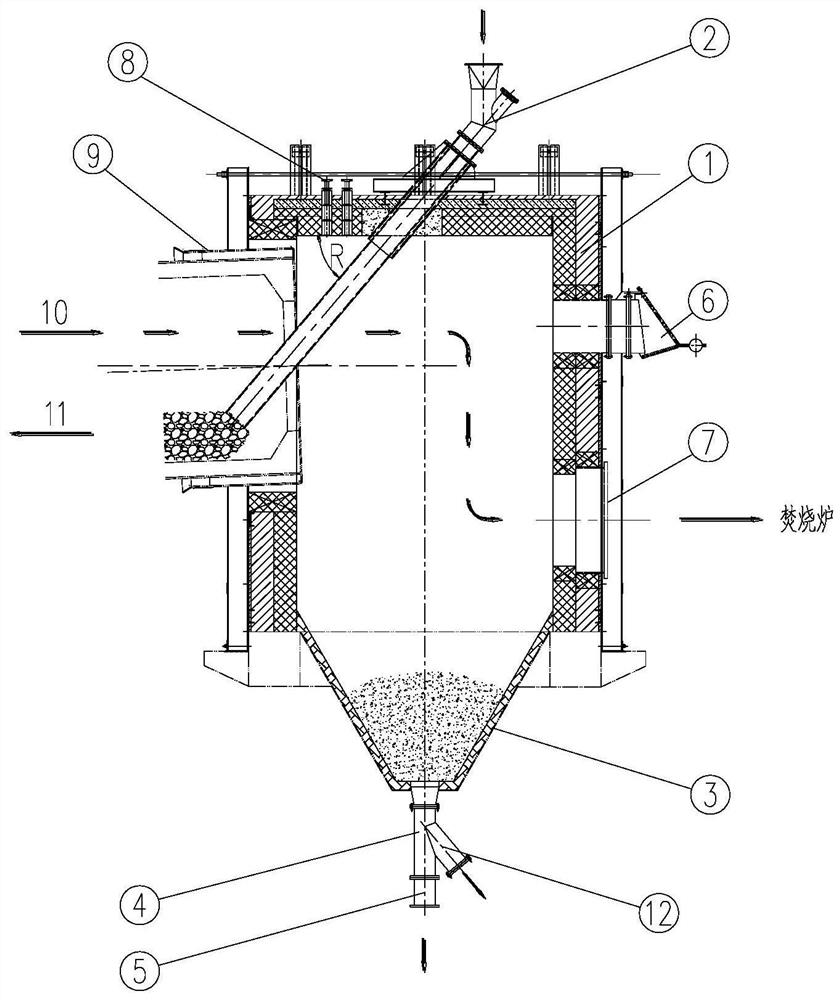

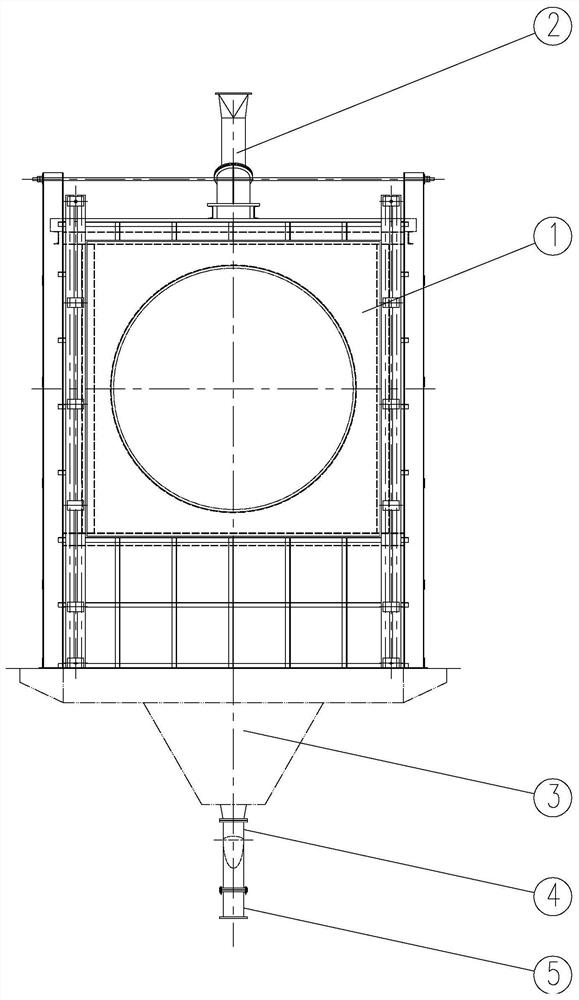

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] like Figure 1-Figure 3 As shown, a feeding chamber for a rotary kiln for calcining needle coke includes a feeding chamber body 1, a feeding device 2, a dust collecting hopper 3, a hot air outlet 7, an explosion relief valve 6, and a temperature and pressure measuring tube 8. The top of the chamber body 1 is provided with a feeding device 2 and a temperature and pressure measuring tube 8. A connection port is left on the side where the feeding chamber body 1 is connected to the rotary kiln, and an explosion relief valve 6 is installed on the upper part of the feeding chamber body 1 opposite to the interface of the rotary kiln. A hot air outlet 7 is reserved below the explosion relief valve 6, a dust collecting hopper 3 is provided at the bottom of the feeding chamber body 1, and the bottom of the feeding device 2 extends into the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com