Large-span bridging gantry crane and construction method thereof

A construction method and large-span technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve problems such as the inability of hoisting technology to complete the construction, and achieve easy split-type hoisting and installation, ensure stability, and improve installation accuracy. and construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

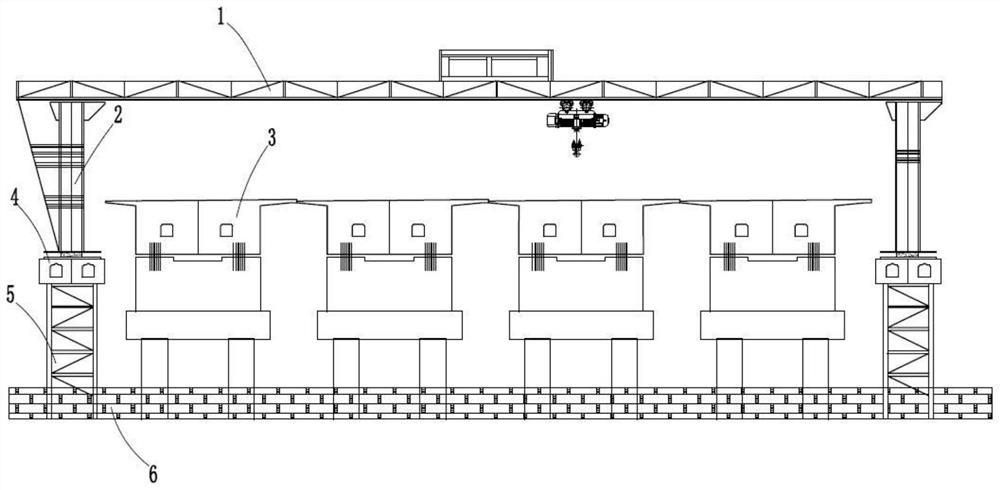

[0047] Such as Figure 1 to Figure 5As shown, the long-span bridge erecting gantry crane of this embodiment includes temporary track bridges 4 arranged on both sides of the existing river-crossing bridge body 3, sliding tracks are arranged on the temporary track bridge 4, and also includes temporary track bridges arranged on both sides of the existing river-crossing bridge body 3. The gantry crane gantry 1 above the bridge body 3 across the river is connected with a support leg 2 below the gantry crane gantry 1, and the lower end of the support leg 2 is provided with a chute seat corresponding to the sliding track.

[0048] The long-span bridge erecting gantry crane in this embodiment skillfully starts from the construction point of view, setting temporary track bridges on both sides of the existing cross-river bridge, setting tracks on the track bridge, and configuring gantry cranes across the existing river-crossing bridge The outriggers of the gantry crane gantry and the tr...

Embodiment 2

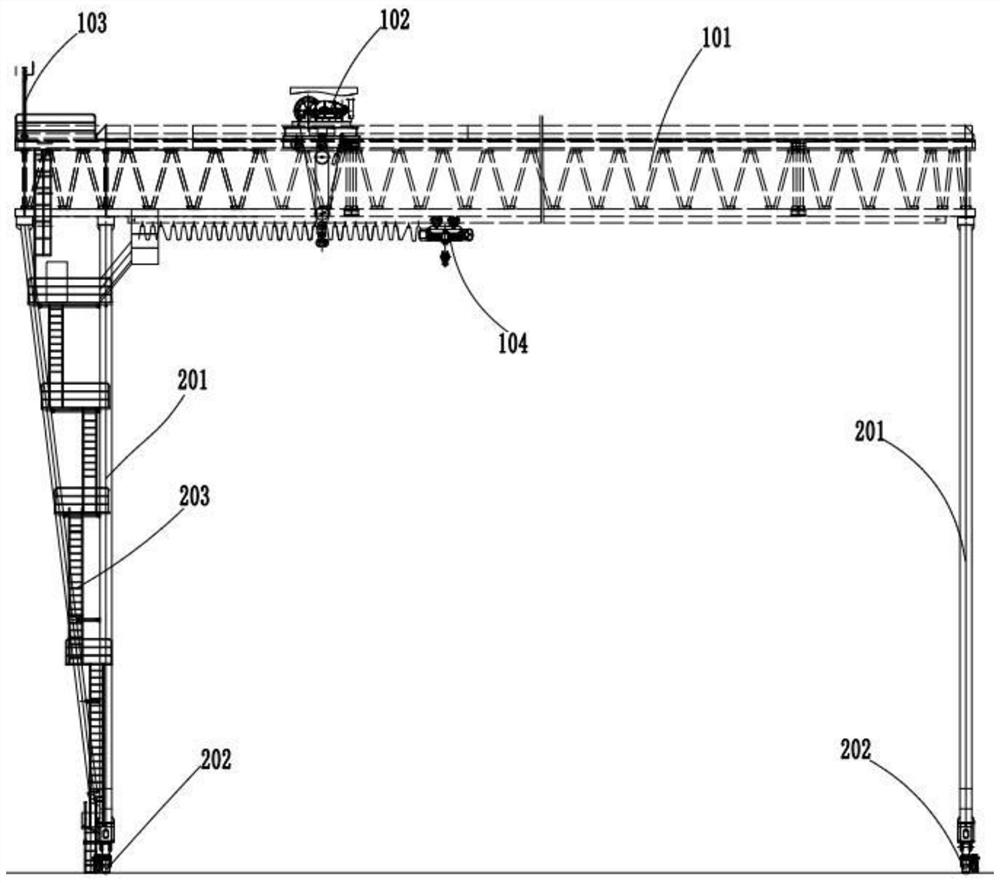

[0050] Such as Figure 1 to Figure 5 As shown, according to the long-span bridge erecting gantry crane described in Embodiment 1, the gantry crane gantry 1 of this embodiment includes a main girder 101, on which a traveling mechanism 102 and a lifting trolley 104 are arranged, and on the main girder 101 there are also A lightning protection device 103 is provided.

[0051] In this embodiment, the main beam 101 is formed by splicing multiple beam segments. The main beam is divided into multi-section beam segment structure, which is convenient for detachable hoisting and installation.

[0052] Such as figure 2 As shown, the outrigger 2 includes a outrigger frame 201 , a chute seat 202 matching the sliding track is provided at the lowermost end of the outrigger frame 201 , and a staircase 203 is also provided on one of the outrigger frames 201 .

[0053] Further, in this embodiment, two gantry cranes 1 are provided on the temporary track bridge 4 . Two gantry cranes are inst...

Embodiment 3

[0055] Such as Figure 1 to Figure 5 As shown, according to the long-span bridge erecting gantry crane described in embodiment 1 or embodiment 2, the temporary track bridge 4 of this embodiment includes a steel box girder and a plurality of pier supports 5, and the steel box girder is composed of a plurality of pier supports 5 Supporting, the sliding track is arranged on the steel box girder, and the foundation pile is connected under the pier support 5, and the lower end of the foundation pile is arranged in the underwater concrete base 6.

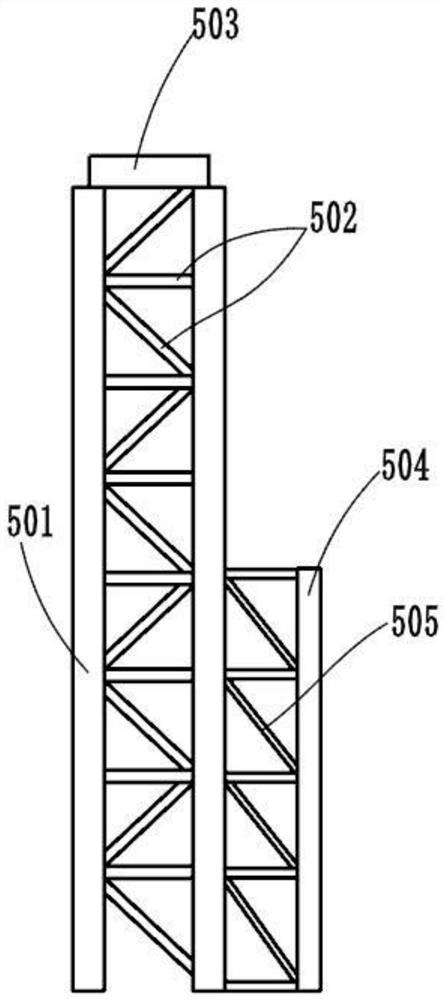

[0056] In this embodiment, the bridge pier support 5 includes four steel pipe foundation piles 501, and each of the bridge pier supports 5 is provided with a flow blocking part in front of it, and the flow blocking part includes a drainage vertical shaft arranged approximately parallel to the steel pipe foundation piles 501. Pile 504, a diversion support is connected between the drainage vertical pile 504 and the steel pipe foundation pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com