Waste rock recycling disposal method for refuse dump

A waste dump and recycling technology, which is applied in the field of disposal of waste rocks in dump dumps, achieves significant environmental benefits, saves storage space, and reduces production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

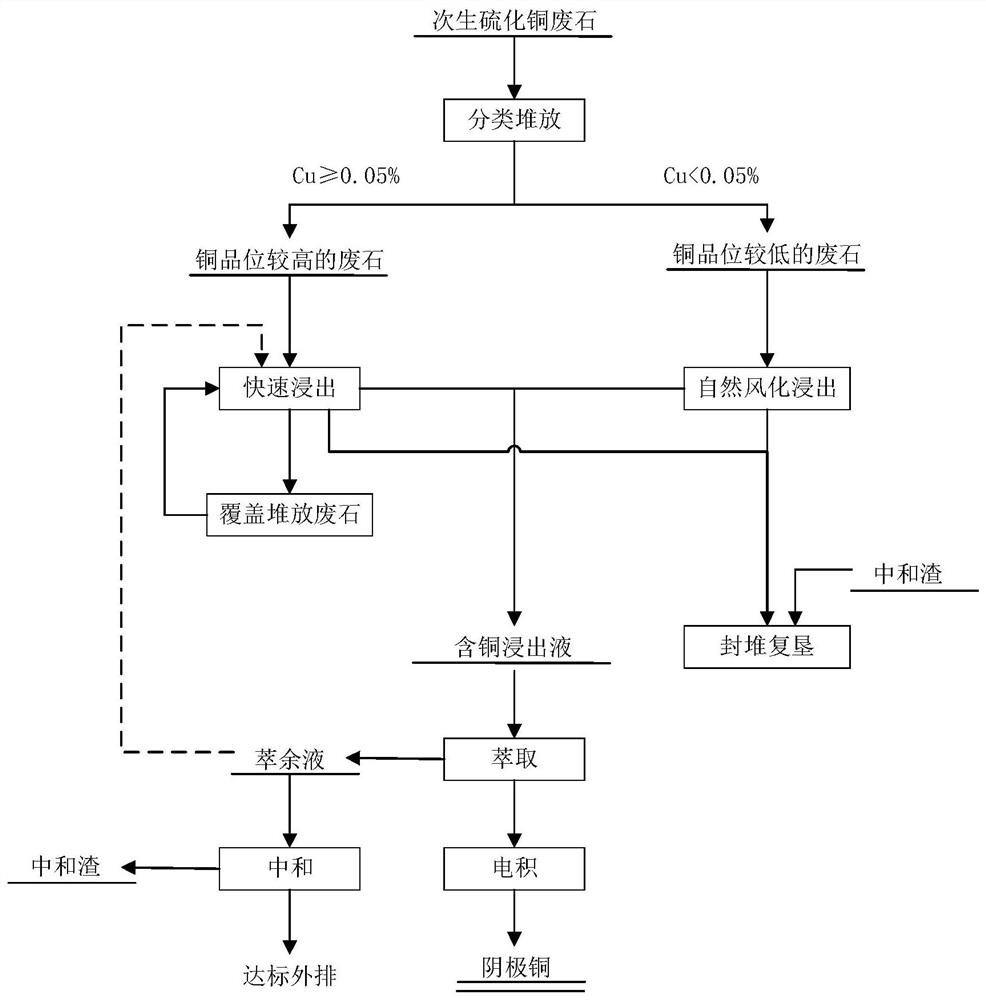

Method used

Image

Examples

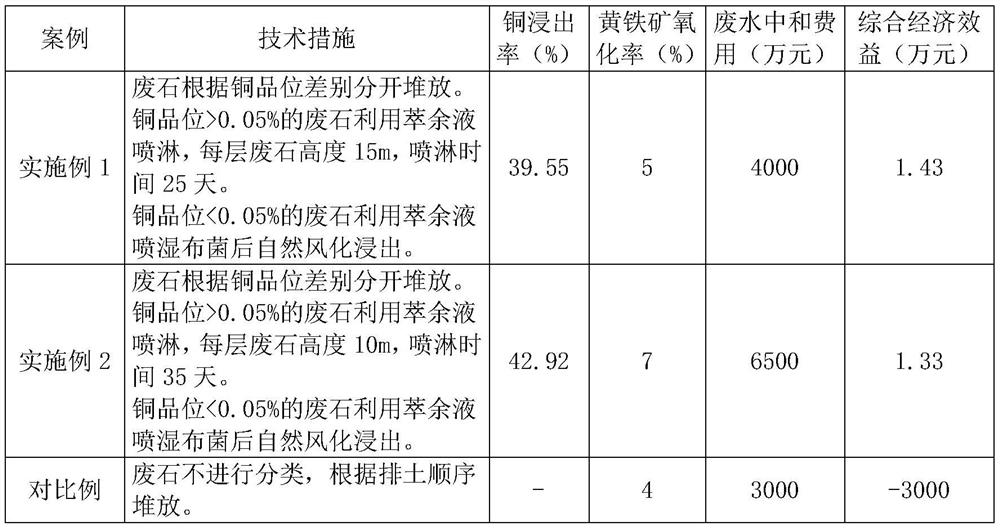

Embodiment 1

[0034] A mine produces 10 million tons of secondary copper sulfide ore each year, including 6 million tons of higher-grade waste rock with a copper grade > 0.05% (average copper grade 0.13%), and 4 million tons of lower-grade waste rock with a copper grade < 0.05% tons (average copper grade 0.036%). The copper minerals are mainly chalcocite and copper blue, containing a small amount of refractory copper minerals, such as pyrite; the content of pyrite is relatively high (average content 5.60%), and copper minerals and pyrite are closely symbiotic; veins The stone minerals are mainly quartz, and the content of acid-consuming gangue is low. The two waste rocks are piled separately. The higher-grade waste rocks are stacked at a height of 15m per layer, and the raffinate is continuously sprayed (sulfuric acid concentration ~ 10g / L, iron ion concentration ~ 10g / L) for 25 days, and then the higher-grade waste rocks are covered, and the spraying is continued Leach copper. After the...

Embodiment 2

[0036] A mine produces 10 million tons of secondary copper sulfide ore each year, including 6 million tons of higher-grade waste rock with a copper grade > 0.05% (average copper grade 0.13%), and 4 million tons of lower-grade waste rock with a copper grade < 0.05% tons (average copper grade 0.036%). The copper minerals are mainly chalcocite and copper blue, containing a small amount of refractory copper minerals, such as pyrite; the content of pyrite is relatively high (average content 5.60%), and copper minerals and pyrite are closely symbiotic; veins The stone minerals are mainly quartz, and the content of acid-consuming gangue is low. The two waste rocks are piled separately. Higher-grade waste rocks are stacked at a height of 10m per layer, continuously sprayed with raffinate (sulfuric acid concentration ~ 10g / L, iron ion concentration ~ 10g / L) for 35 days, and then covered with higher-grade waste rocks, and continue to spray Leach copper. After the low-grade waste rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com