Graphene asphalt additive and preparation method thereof

A technology of olefin pitch and additives, which is applied in the field of graphene pitch additives and its preparation, can solve the problems of excessive manpower and material resources, waste of manpower and material resources, traffic jams, etc., and achieve the effect of improving physical and chemical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

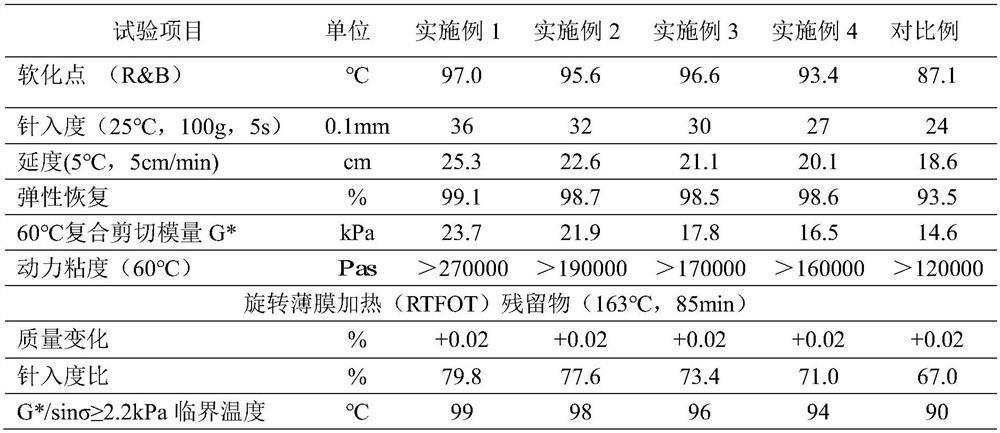

Embodiment 1

[0017] In terms of parts by mass, disperse 1 part of graphene oxide in 1000 parts of water, ultrasonically disperse into a uniform yellow transparent colloidal solution, then add 60 parts of NaOH and 50 parts of monochloroacetic acid, ultrasonic 180min, after fully reacting, the The solution was hot-filtered at 65°C to remove impurity ions, centrifuged and dried under vacuum at 65°C to obtain carboxylated graphene oxide.

[0018] In parts by mass, after stirring and mixing 5 parts of carboxylated graphene oxide and 500 parts of absolute ethanol in proportion, add 2 parts of γ-(2,3-glycidyloxy)propyltrimethoxysilane under water bath conditions , fully reacted at 60°C for 24 hours, centrifuged and dried to obtain surface-modified carboxylated graphene oxide; surface-modified carboxylated graphene oxide, 5 parts of alkyl glucoside, 6 parts of polyvinyl alcohol, 12 parts of boric acid ester, 6 parts of polymethyl methacrylate are mixed to obtain a premix; the premix is thermally...

Embodiment 2

[0020] In terms of parts by mass, disperse 1 part of graphene oxide in 1000 parts of water, ultrasonically disperse into a uniform yellow transparent colloidal solution, then add 60 parts of NaOH and 50 parts of monochloroacetic acid, ultrasonic 180min, after fully reacting, the The solution was hot-filtered at 65°C to remove impurity ions, centrifuged and dried under vacuum at 65°C to obtain carboxylated graphene oxide.

[0021] In parts by mass, after stirring and mixing 10 parts of carboxylated graphene oxide and 1000 parts of absolute ethanol in proportion, add 3 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane in a water bath , fully reacted at 60°C for 24 hours, centrifuged and dried to obtain surface-modified carboxylated graphene oxide; surface-modified carboxylated graphene oxide, 6 parts of alkyl glucoside, 8 parts of polyvinyl alcohol, 16 parts of boric acid ester, 8 parts of polymethyl methacrylate are mixed to obtain a premix; the premix is thermally mixed wi...

Embodiment 3

[0023] In terms of parts by mass, disperse 1 part of graphene oxide in 1000 parts of water, ultrasonically disperse into a uniform yellow transparent colloidal solution, then add 60 parts of NaOH and 50 parts of monochloroacetic acid, ultrasonic 180min, after fully reacting, the The solution was hot-filtered at 65°C to remove impurity ions, centrifuged and dried under vacuum at 65°C to obtain carboxylated graphene oxide.

[0024] In terms of mass fractions, after stirring and mixing 2.5 parts of carboxylated graphene oxide and 250 parts of absolute ethanol in proportion, add 1 part of γ-(2,3-epoxypropoxy)propyltrimethoxysilane in a water bath , fully reacted at 60°C for 24 hours, centrifuged and dried to obtain surface-modified carboxylated graphene oxide; surface-modified carboxylated graphene oxide, 4 parts of alkyl glucoside, 5 parts of polyvinyl alcohol, 10 parts of boric acid ester, 5 parts of polymethyl methacrylate are mixed to obtain a premix; the premix is thermally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com