A kind of bean paste brewing process

A soy sauce and technology technology, applied in the field of soy sauce brewing technology, can solve the problems that affect consumers' choice of products, high raw material costs and processing costs, and achieve the goals of improving color and flavor, improving physical and chemical indicators, and shortening fermentation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

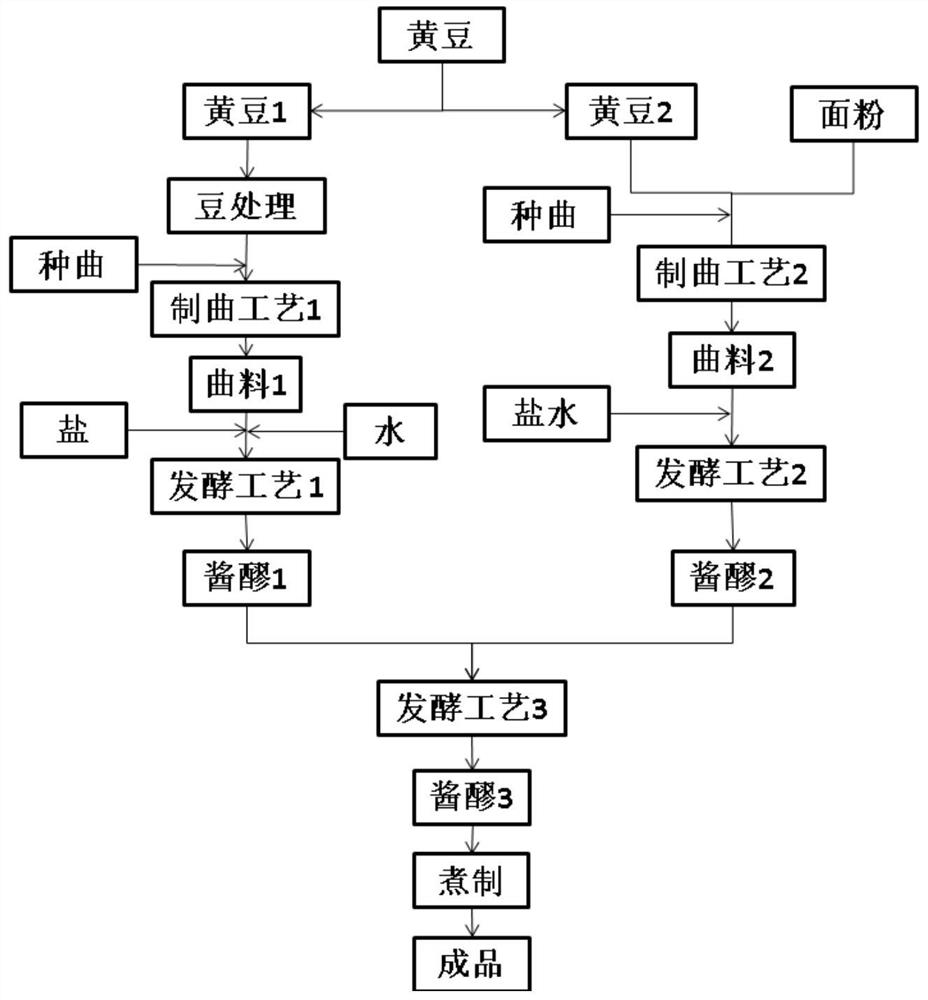

[0055] A kind of embodiment of bean paste brewing process of the present invention, comprises the steps:

[0056] (1) Bean processing: soybeans are divided into two parts of soybean 1 and soybean 2, soybean 1 accounts for 10% of the total weight of soybeans, and soybean 2 accounts for 90% of the total weight of soybeans;

[0057] (2) Preparation of soy mash 1 semi-finished product:

[0058] Add water according to the weight ratio of 1 to soak soybeans 1 for 2.5 hours, steam the soaked soybeans 1, and cook until the cooked beans are not raw, peeled, lumpy, soft and hard, and the beans are complete. Crush and cool to below 40°C;

[0059] Insert the koji species into the crushed soybean 1 according to the weight ratio of 0.05%, and transport it to the aseptic culture room to make koji after mixing evenly. ~40℃, wind frequency 15~50Hz, cultivation time 16h;

[0060] Add edible refined salt to the obtained koji material 1 at an addition amount of 0.5 by weight, and add a small a...

Embodiment 2

[0068] A kind of embodiment of bean paste brewing process of the present invention, comprises the steps:

[0069] (1) Bean processing: soybeans are divided into two parts of soybean 1 and soybean 2, soybean 1 accounts for 20% of the total weight of soybeans, and soybean 2 accounts for 80% of the total weight of soybeans;

[0070] (2) Preparation of soy mash 1 semi-finished product:

[0071] Add water at a weight ratio of 1.5 to soak soybeans 1 for 4 hours, steam the soaked soybeans 1 until the cooked beans are not caught raw, peeled, not lumpy, soft and hard, and the beans are complete. After cooking, crush , cooled to below 40°C;

[0072] Insert the koji species into the pulverized soybean 1 according to the weight ratio of 0.1%, and transport it to the aseptic culture room to make koji after mixing evenly. ~40℃, wind frequency 15~50Hz, cultivation time 20h;

[0073] Add edible refined salt to the koji material 1 obtained by the addition amount of 1 by weight, and add a sm...

Embodiment 3

[0081] A kind of embodiment of bean paste brewing process of the present invention, comprises the steps:

[0082] (1) Bean processing: soybeans are divided into two parts of soybean 1 and soybean 2, soybean 1 accounts for 30% of the total weight of soybeans, and soybean 2 accounts for 70% of the total weight of soybeans;

[0083] (2) Preparation of soy mash 1 semi-finished product:

[0084] Add water according to the weight ratio of 2, soak soybeans 1 for 3 hours, steam the soaked soybeans 1, cook until the cooked beans are not raw, peeled, lumpy, soft and hard, and the beans are complete. After cooking, crush , cooled to below 40°C;

[0085] Insert the koji species into the pulverized soybean 1 according to the weight ratio of 0.15%, and transport it to the aseptic culture room to make koji after mixing evenly. ~40℃, wind frequency 15~50Hz, cultivation time 24h;

[0086] Add edible refined salt to the obtained koji material 1 in an addition amount of 1.5 by weight, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com