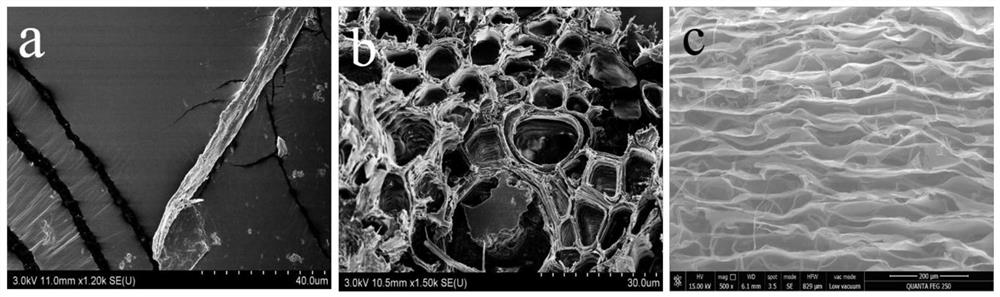

Sodium alginate-palm fiber composite aerogel as well as preparation method and application thereof

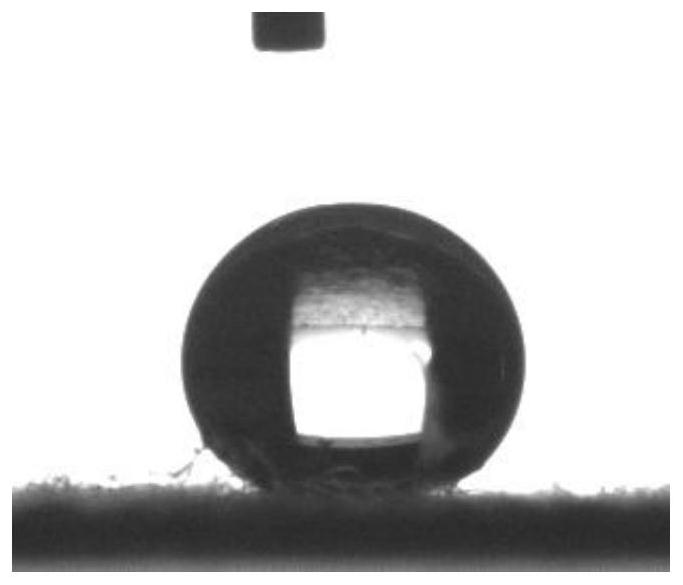

A composite airgel and sodium alginate technology, which is applied in the field of sodium alginate-palm fiber composite airgel and its preparation, can solve the problems of poor mechanical properties, inability to use in the construction field, lack of thermal insulation and sound absorption functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of sodium alginate-palm fiber composite airgel, comprises the steps:

[0036] Mixing the brown silk with the degumming solution and performing microwave treatment to obtain the degummed brown silk; the degumming solution includes sodium hydroxide, hydrogen peroxide, and crude oil and water;

[0037] The degummed palm silk is sequentially subjected to first freeze-drying and crushing to obtain palm microcrystalline cellulose;

[0038] After mixing sodium alginate, water and the palm microcrystalline cellulose, degassing and standing to obtain a composite hydrogel;

[0039] The composite hydrogel is subjected to the second freeze-drying to obtain the sodium alginate-palm fiber composite airgel.

[0040] In the present invention, brown silk is mixed with degumming liquid, and subjected to microwave treatment to obtain degummed brown silk; the degumming liquid includes sodium hydroxide, hydrogen peroxide, crude oil and wa...

Embodiment 1

[0064] 15g sodium hydroxide, 20g and crude oil, 15mL concentration are 30% hydrogen peroxide aqueous solution and 1015mL water mix, obtain degumming liquid; and crude oil; according to the ratio of brown silk and degumming liquid: 1g: 23mL, mix 45g of brown silk and degumming liquid, carry out microwave treatment, the temperature of microwave treatment is 95 ℃, the power is 500W, and the time of microwave treatment is 1.2h After the microwave treatment is completed, filter, then rinse the gained solid 5 times according to the ratio of 3600mL deionized water / 1g brown silk, to obtain degummed brown silk;

[0065] The degummed brown silk was frozen at -17°C for 4 hours, then freeze-dried at a temperature of -90°C and a vacuum of 5 Pa for 36 hours, and then pulverized 5 times in a traditional Chinese medicine pulverizer at a speed of 1000r / min. 2min, the time between pulverization is 5min, obtains 50g palm microcrystalline cellulose, and the length of described palm microcrystalli...

Embodiment 2

[0082] 18g sodium hydroxide, 22g and crude oil, 20mL concentration are 30% hydrogen peroxide and 1020mL water are mixed, obtain degumming liquid; Described and crude oil is the YS-85 model and Crude oil; mix 48g of brown silk with the degumming solution according to the proportion of brown silk and degumming solution 1g: 21.9mL, and carry out microwave treatment. The temperature of microwave treatment is 95°C, the power is 550W, and the time of microwave treatment is 1.5h After the microwave treatment is completed, filter, then rinse the gained solid with 4320mL / 1g deionized water for 5 times to obtain degummed brown silk;

[0083] The degummed brown silk was frozen at -17°C for 4 hours, then freeze-dried at a temperature of -90°C and a vacuum of 5 Pa for 36 hours, and then pulverized 5 times in a traditional Chinese medicine pulverizer at a speed of 1000r / min. 3min, the time between pulverization is 5min, obtains 50g palm microcrystalline cellulose, and the length of describe...

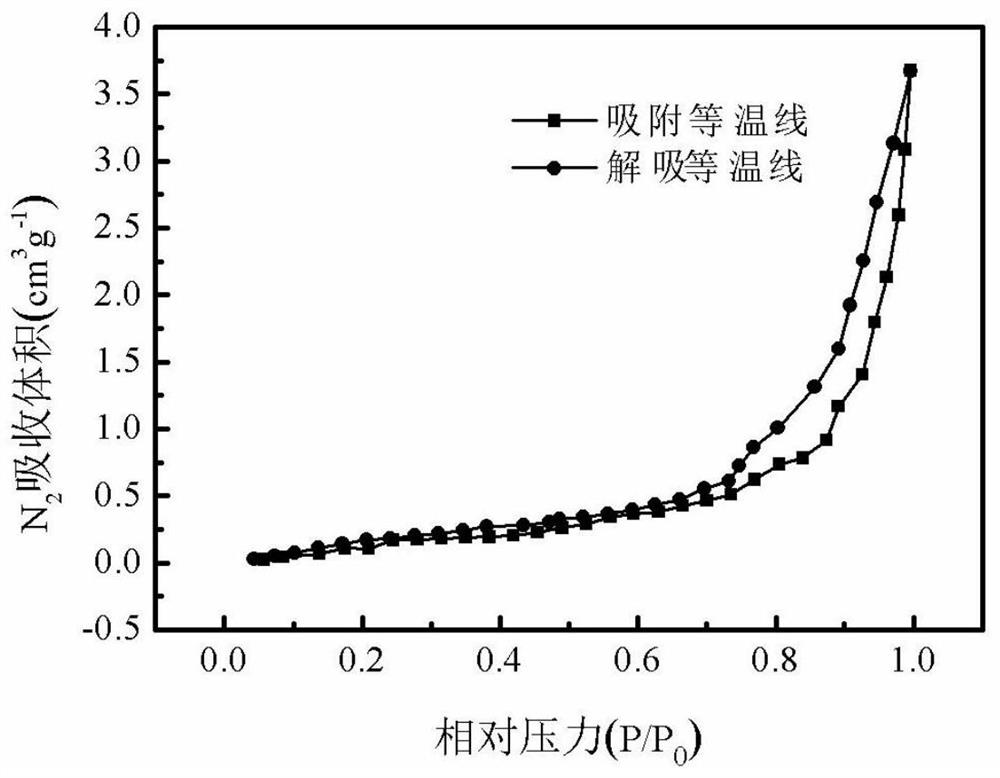

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com