A kind of anti-aging polymer cement waterproof coating and preparation method thereof

A waterproof coating and polymer technology, applied in coatings and other directions, can solve the problems of flexibility, performance and characteristics of waterproof coatings without polymer cement, achieve excellent waterproof effect, widen the scope of use, and simple manufacturing methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

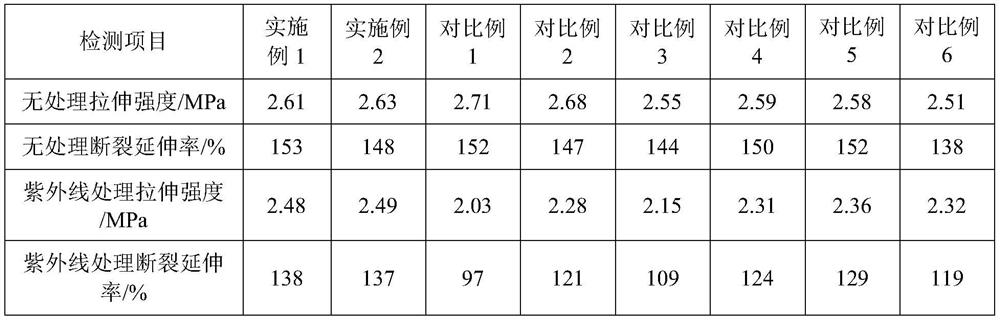

Examples

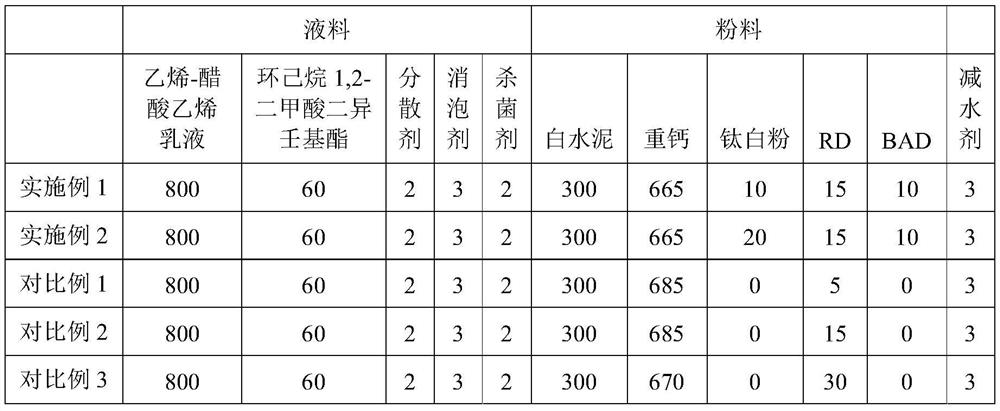

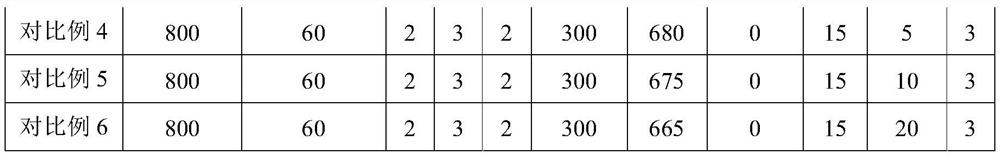

Embodiment 1

[0045] This embodiment provides an anti-aging polymer cement waterproof coating and a preparation method thereof.

[0046] Liquid material: add 140 parts by weight of deionized water to the liquid material stirring tank, open the disperser of the stirring tank, keep the rotating speed at 1000 rpm, then mix 800 parts by weight of ethylene-vinyl acetate emulsion, 60 weight parts Parts of diisononyl cyclohexane 1,2-dicarboxylate were respectively metered and added to the liquid material stirring cylinder to disperse for 10 minutes, then the stirring speed was reduced to 800 rpm, and then 2 parts by weight of dispersant, 3 parts by weight of defoamer and 2 parts by weight of bactericide are added into the liquid material mixing tank after metering, and the liquid material can be packaged after stirring for 20 minutes.

[0047] Powder: Turn on the weightless powder mixer, keep the rotation speed at 600 rpm, then add 300 parts by weight of white cement to the powder mixing tank afte...

Embodiment 2

[0050] This embodiment provides an anti-aging polymer cement waterproof coating and a preparation method thereof.

[0051] Liquid material: add 140 parts by weight of deionized water to the liquid material stirring tank, open the disperser of the stirring tank, keep the rotating speed at 1000 rpm, then mix 800 parts by weight of ethylene-vinyl acetate emulsion, 60 weight parts Parts of cyclohexane 1,2-diisononyl dicarboxylate were respectively metered and added to the liquid material stirring cylinder to disperse for 10 minutes, then the stirring speed was reduced to 800 rpm and then 2 parts by weight were dispersed 3 parts by weight of antifoaming agent and 2 parts by weight of bactericide are added into the liquid material mixing tank after metering, and the liquid material can be packaged after stirring for 20 minutes.

[0052] Powder: Turn on the weightless powder mixer, keep the rotation speed at 600 rpm, then add 300 parts by weight of white cement to the powder mixing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com