Iron tailing large-slump high-strength conductive concrete and preparation method thereof

A conductive concrete and slump technology, which is applied in the field of building material concrete, can solve the problems of concrete strength and slump, reduce concrete strength, carbon fiber agglomeration, etc., achieve excellent particle gradation, improve electrical conductivity, and slump big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

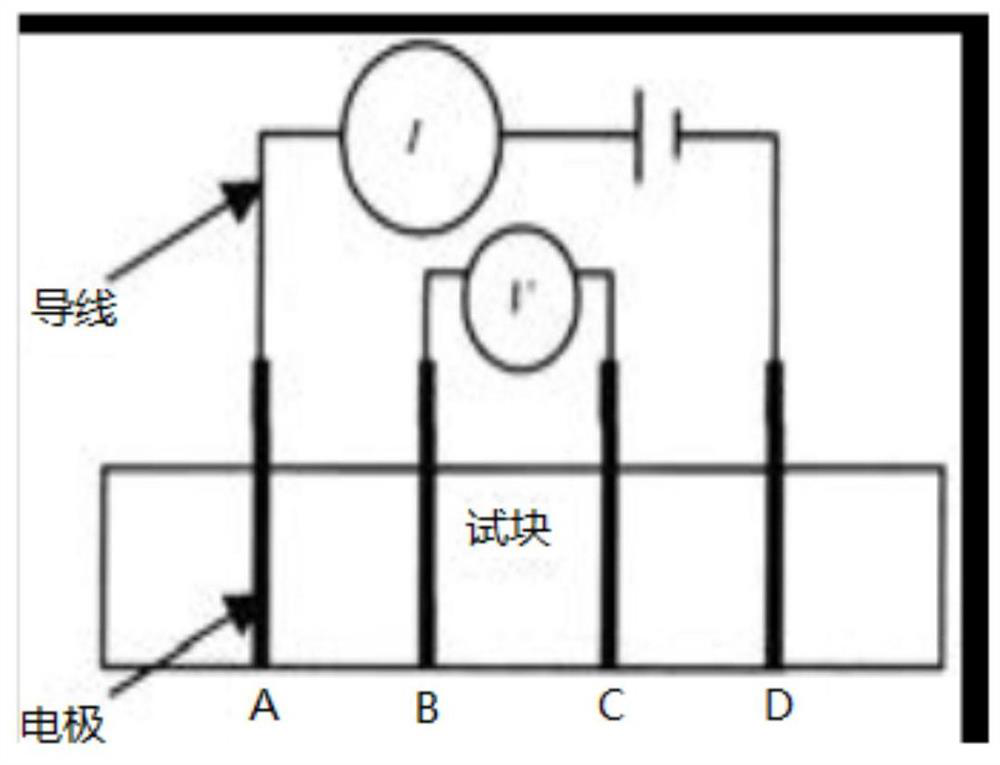

Method used

Image

Examples

preparation example Construction

[0055]A method of preparing a high-strength conductive concrete as described above with the above-mentioned steps of tail mine, including the following steps:

[0056]Step 1, weigh the raw material components according to the following: cement 250 ~ 450, silicon ash 30 ~ 60, fly ash 40 to 90, iron mine waste stone 1050 ~ 1180, iron tail ore 570 ~ 740, iron fine Powder 150 ~ 220, conductive promoter 3.2 to 12.0, expansion agent 25.6 to 60.0, aqueous dispersant 1.6 to 6.0, polycarboxylic acid water water water 7.8 ~ 10.8, water 170 to 175, wherein the unit is kg / m3.

[0057]Step 2, the weighing conductive accelerator, aqueous dispersant, and polycarboxylic acid water use are mixed into water;

[0058]Step three, weigh iron ore waste stone, iron tail ore, iron fine powder, cement, silica gray, fly ash and expansion agent were added to the mixer for 1min;

[0059]Step 4, the mixture obtained by stirring step di2 is added to the stirrer in the mixer, stirred for 2 min to the desired working perfor...

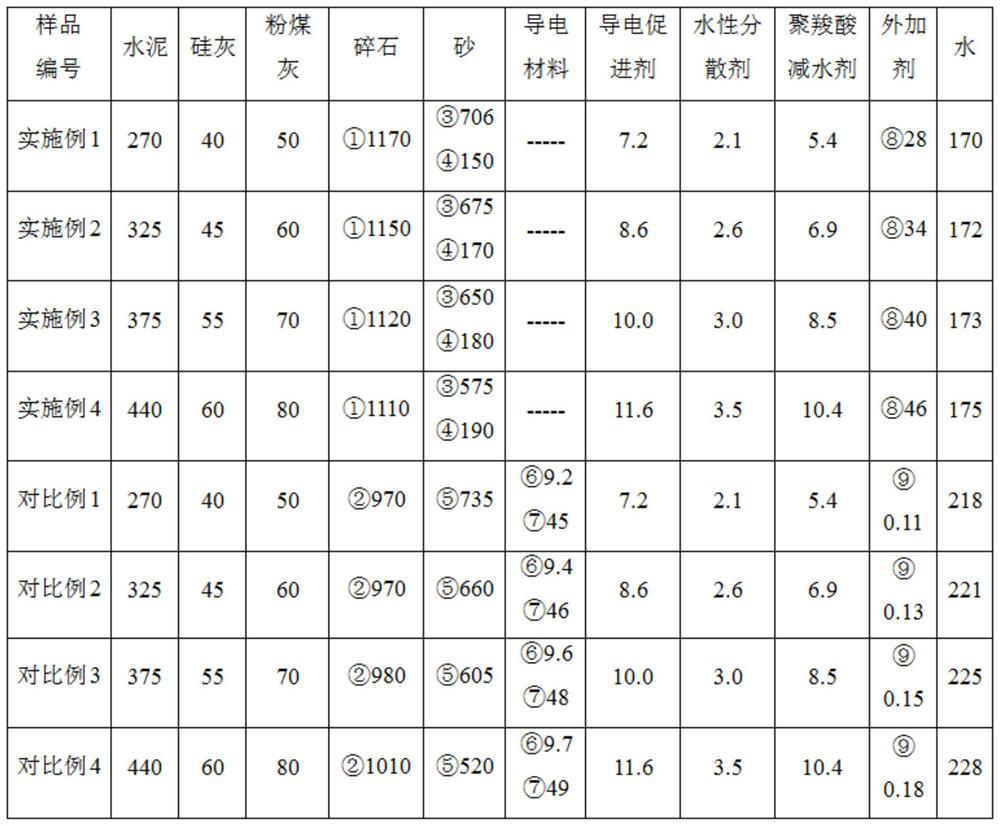

Embodiment 1

[0077]The conductive concrete components of the present embodiment are distributed, for examplefigure 2 Indicated.figure 2 In the middle, 1 is iron mine waste stone; 2 is limestone, its particle size is 5 ~ 25mm; 3 is iron tail ore; 4 is iron fine powder; 5 is natural sand, its fineness modulus is 1.8; 6 is carbon fiber That is, 6 mm short-cut carbon fiber; 7 is graphite, that is, 200 meteorite scales graphite powder; 8 is an expansion agent, i.e., UEA (U-type expansion agent); ⑨ is a defoamer, i.e., phosphate tributyl. In the present embodiment, the iron ore waste stone has a iron content of 20%, the particle size is 20 mm; the iron tail ore contains is 15%, the fineness modulus is 2.0; the iron-rich amount of iron powder is 60 %, Fine particles of 100 mesh.

[0078]The basic performance of the conductive concrete obtained by this embodimentimage 3 .

Embodiment 2

[0080]The conductive concrete components of the present embodiment are distributed, for examplefigure 2 Indicated. In this embodiment, the iron ore waste stone has a iron content of 15%, the particle size is 25 mm; the iron tail ore contains 10%, the fineness modulus is 1.8; the iron-rich amount of iron is 50 %, Fine particles of 200 mesh.

[0081]The basic performance of the conductive concrete obtained by this embodimentimage 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com