Small machining tool cleaning equipment for machinery factory

A technology for mechanical processing and cleaning equipment, which is applied to mechanical equipment, cleaning methods using tools, machines/engines, etc. It can solve the problems of inconvenient cleaning of mechanical processing tools and achieve a comprehensive washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

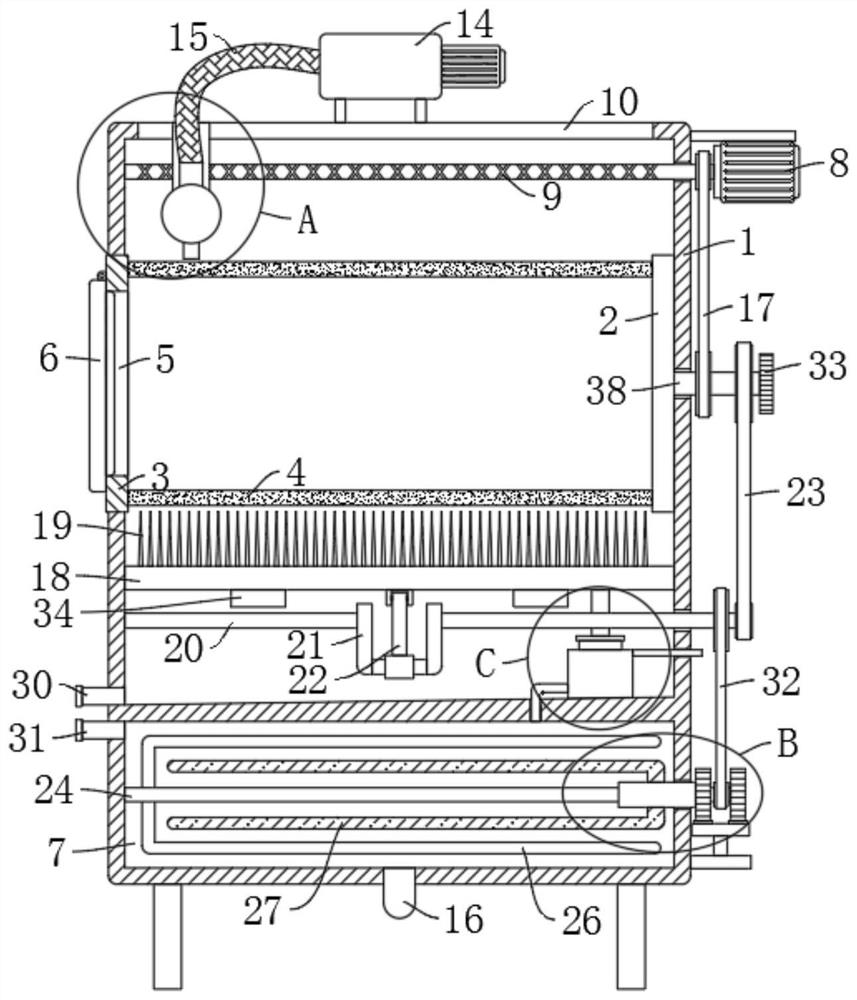

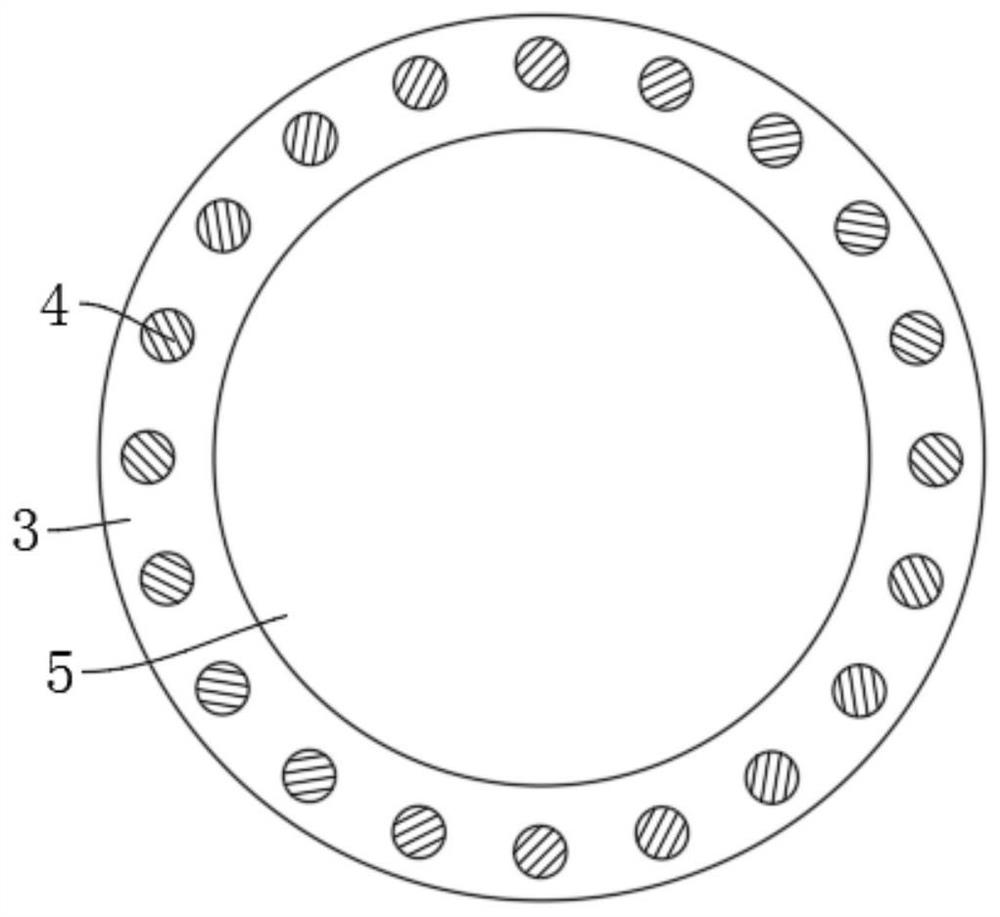

[0031] refer to Figure 1-6 , a kind of cleaning equipment for small-scale machining tools used in a machinery factory, comprising a cleaning box 1, the left and right side walls of the cleaning box 1 are respectively rotatably connected with a plurality of linearly distributed left disks 3 and right disks 2, and the left disk 3 and the right A plurality of circumferentially distributed support rods 4 are fixedly connected between the disks 2. The side wall of the left disk 3 extends to the outer wall of the cleaning box 1 and is provided with a placement groove 5. The outer wall of the placement groove 5 is rotatably equipped with an end cover 6 for cleaning. The side wall of the lower end of the box 1 is provided with a drainage pipe 30, the lower end of the cleaning box 1 is fixedly equipped with a mixing box 7, the side wall of the mixing box 7 is provided with a liquid feeding pipe 31, and the upper end of the cleaning box 1 is fixedly installed with a water pump 14, a wat...

Embodiment 2

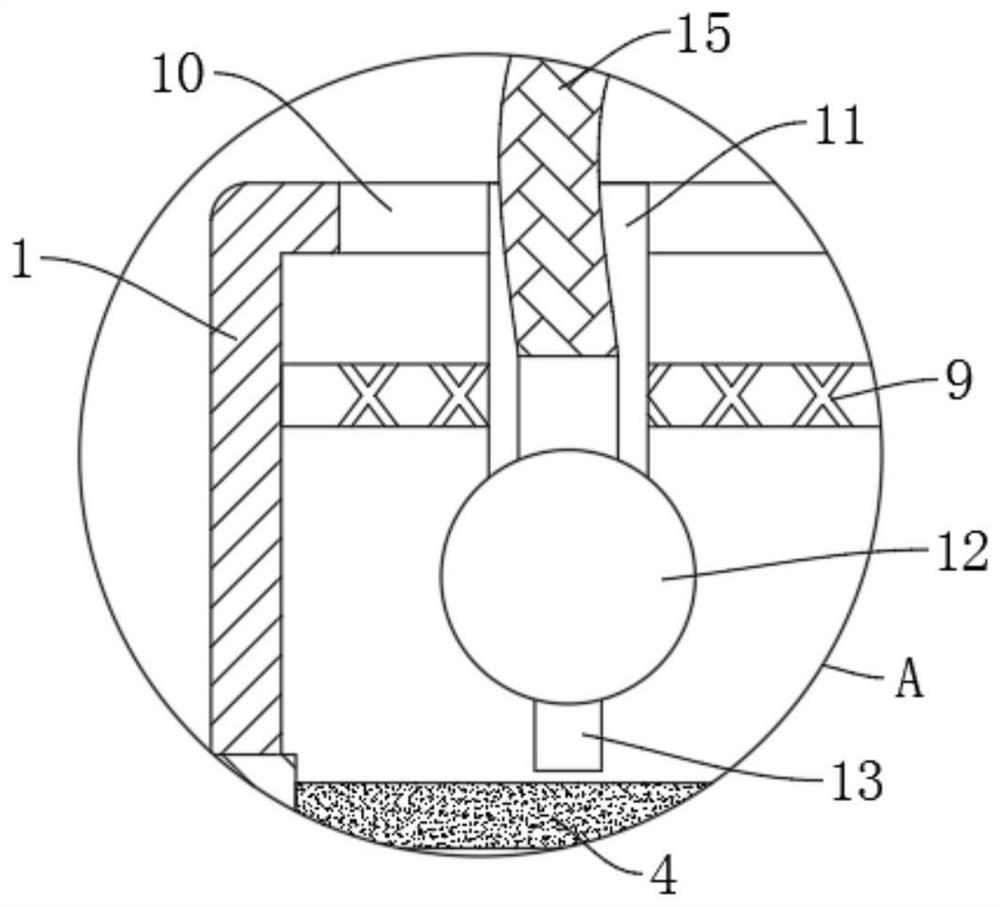

[0036] refer to figure 1 and image 3, is basically the same as Embodiment 1, furthermore: the reciprocating flushing device includes a motor 8 fixedly installed on the side wall of the cleaning box 1, and the output end of the motor 8 is fixedly connected with a reciprocating lead screw 9 extending to the top of the cleaning box 1, The outer wall of the reciprocating lead screw 9 is provided with a lead screw slider 11, the upper end of the cleaning box 1 is provided with a chute 10 cooperating with the lead screw slider 11, and the lower end of the lead screw slider 11 is fixedly connected with a transverse tube 12, and the transverse tube The lower end of 12 is fixedly equipped with a plurality of evenly distributed nozzles 13, the output pipe of the water pump 14 is fixedly connected with the horizontal pipe 12 through the telescopic hose 15, and the side walls of the plurality of right discs 2 are fixedly connected with a nozzle extending to the cleaning tank. 1 The rota...

Embodiment 3

[0038] refer to figure 1 and Figure 4 , which is basically the same as in Embodiment 1, furthermore: the strengthened cleaning device includes a plurality of linearly distributed cleaning plates 18 that are slidably connected to the bottom of the cleaning box 1, and the upper ends of the multiple cleaning plates 18 are provided with evenly distributed long hairs. Brush 19, the lower end of a plurality of cleaning plates 18 is fixedly connected by connecting plate 34, and the inner bottom side wall of cleaning box 1 is connected with rotating rod 20 in rotation, and the middle part of rotating rod 20 is fixedly equipped with crankshaft 21, and cleaning plate 18 The lower end of the connecting rod 22 is rotatably connected to the connecting rod 22, and the other end of the connecting rod 22 is rotatably connected to the outer wall of the crankshaft 21. The right end of the rotating rod 20 is connected to the rotating shaft 38 through the second chain drive 23. During flushing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com