Mechanically sealing device for main circulating pump for seawater desulfuration

A technology of mechanical sealing device and main circulation pump, which is applied in the direction of mechanical equipment, pumping device components for elastic fluid, pumps, etc., and can solve the problem of reducing the working temperature of the seal, uneven cooling of the seal, and reduced sealing performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

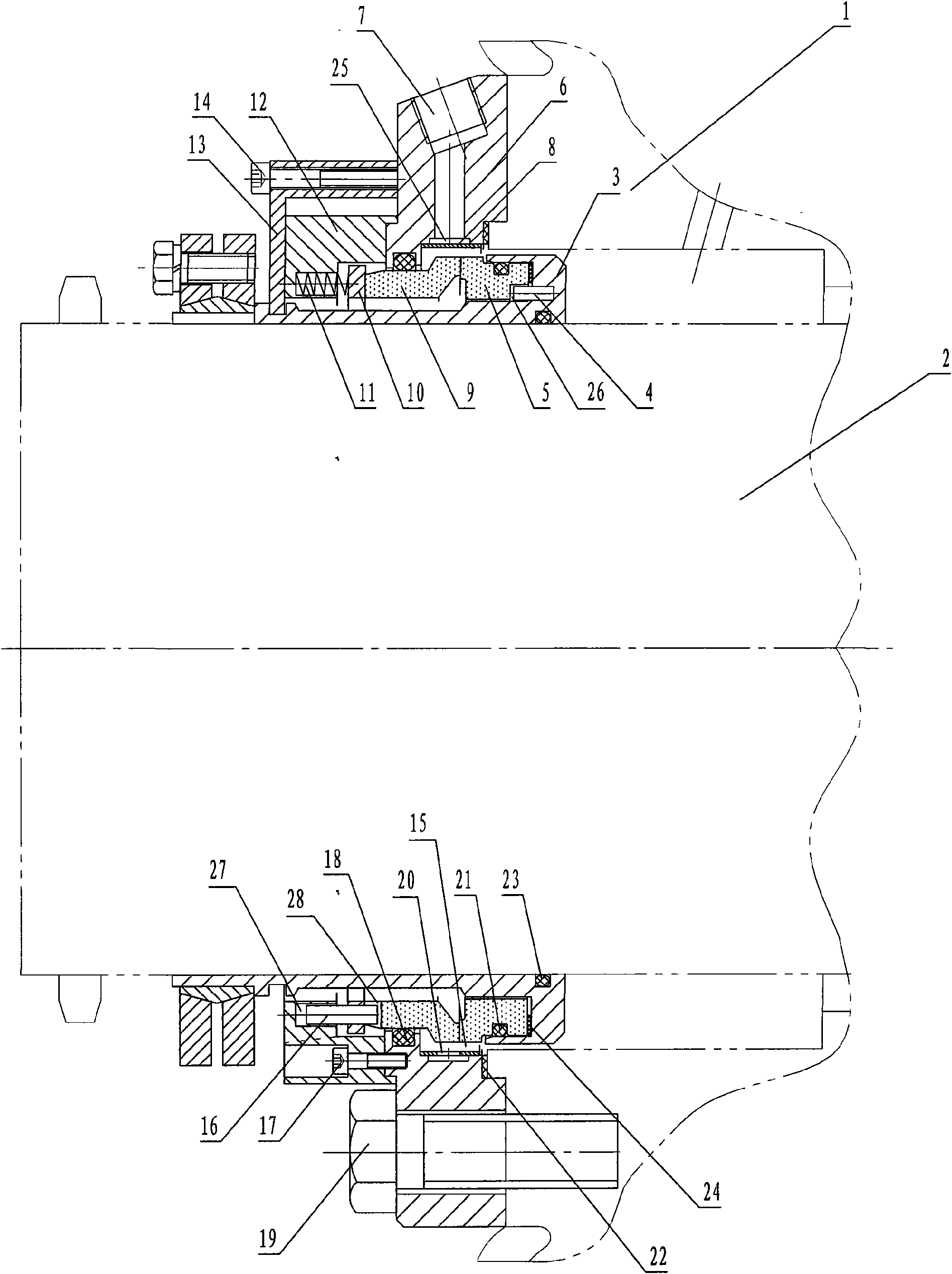

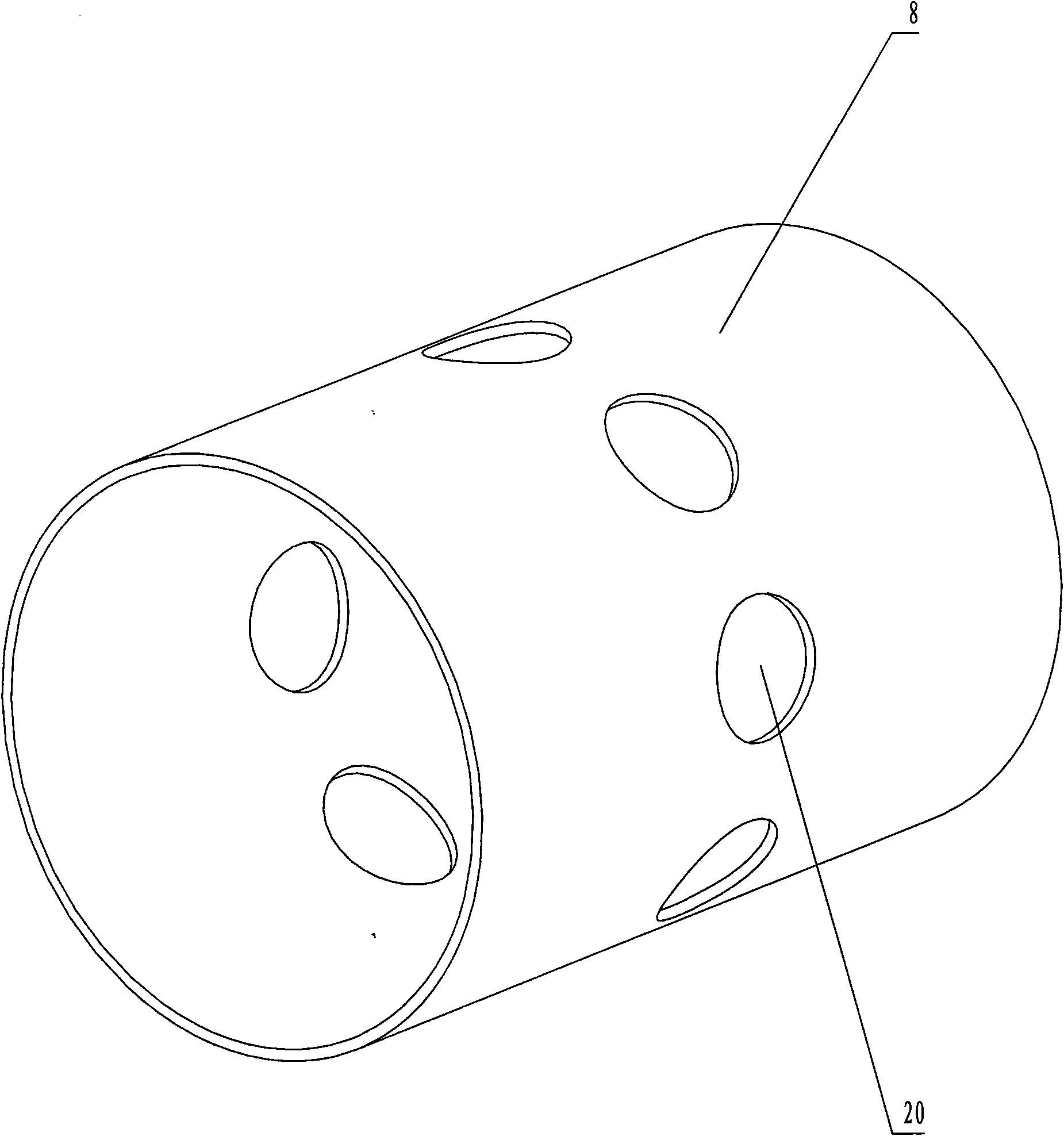

[0010] like figure 1 , figure 2 As shown, in this specific embodiment, the mechanical seal device for the seawater desulfurization main circulation pump of the present invention includes a moving ring assembly, a static ring assembly, a seal seat 6, a spacer sleeve 8 and a shaft sleeve 3 tightly matched with the pump shaft 2; An O-ring 23 is provided at the joint between the right end of the shaft sleeve 3 and the pump shaft 2; the moving ring assembly is connected to the shaft sleeve 3; the static ring assembly is connected to the seal seat 6; the moving ring assembly includes a moving ring 5, The transmission pin 4 and the moving ring O-ring 21 and the washer 24 arranged between the moving ring 5 and the shaft sleeve 3; one end of the transmission pin 4 is connected to the shaft sleeve 3, and the other end is located In the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com