Novel spray drying device for preventing grease oxidation

A new type of oil oxidation technology, applied in spray evaporation, chemical instruments and methods, evaporator accessories, etc., can solve problems such as oil oxidation, reduce powder shelf life, etc., to reduce the loss rate, prevent oil oxidation, and prolong shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

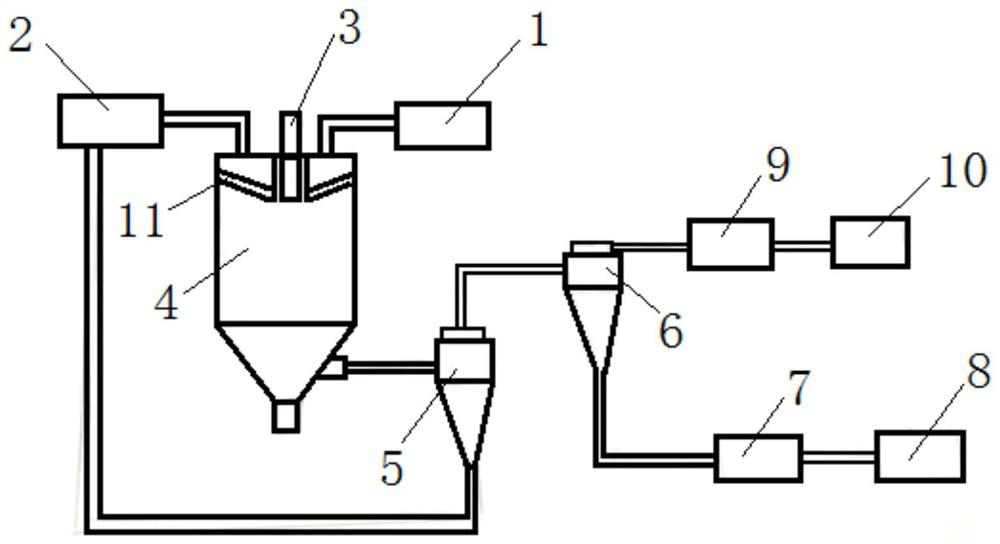

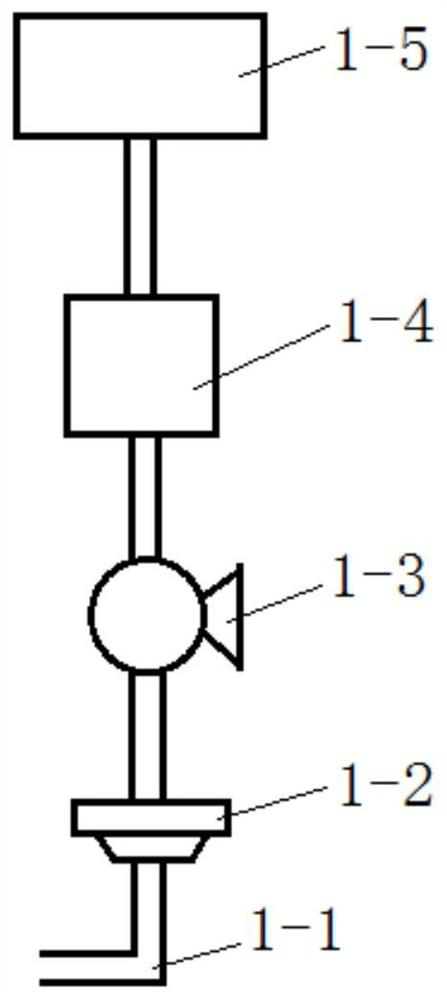

[0029] Specific implementation mode one: see Figure 1-4 This embodiment will be described. The new spray drying device for preventing grease oxidation described in this embodiment includes a hot air system 1, a material supply system 2, a spray drying system, a separation collection system and an emptying system 10:

[0030] The hot air system 1 is connected to the spray drying system, and is used to provide the spray drying system with hot air for drying materials;

[0031] The material supply system 2 is connected with the spray drying system, and is used to provide raw materials for the spray drying system;

[0032] The spray drying system is connected to the separation and collection system, and is used to transport the nanoparticles obtained after the raw materials are atomized and dried to the separation and collection system;

[0033] The separation and collection system includes several cyclone separators, material cooling device 7 and collection device 8 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com