Pulping process of composite nut beverage

A nut and pulp refining technology, which is applied in the field of compound nut beverage refining technology, can solve problems such as single taste, taste change, and low nutritional content, and achieve the effects of improving nutritional content, preventing oil oxidation, and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

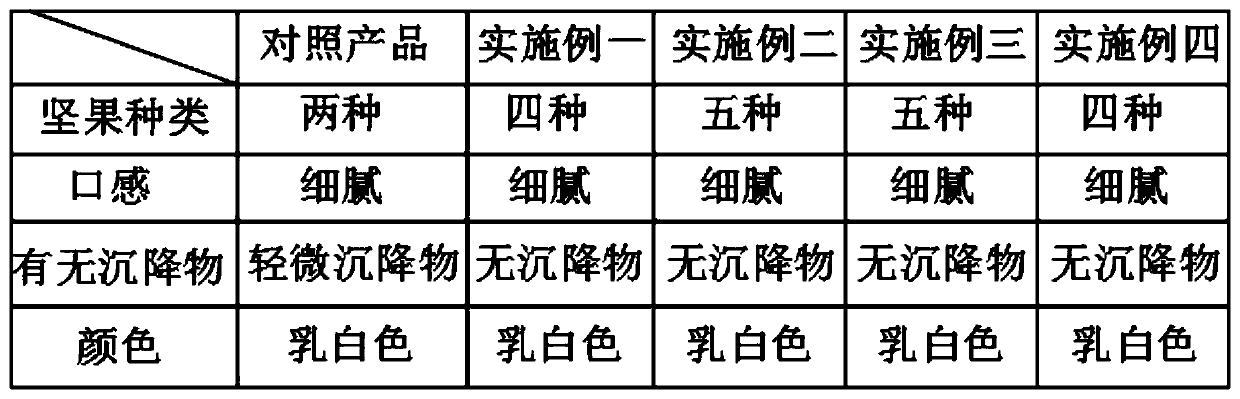

Examples

Embodiment 1

[0027] A compound nut beverage refining process, comprising the following steps:

[0028] Step 1, shelling: compound nuts include walnuts, hazelnuts, almonds, lotus seeds, cashew nuts and macadamia nuts, and the compound nuts are calculated by weight percentage, 4 parts of walnuts, 4 parts of lotus seeds, 3 parts of cashew nuts and 4 parts of macadamia nuts, and the compound nuts Drying is required before processing, and the moisture content inside the compound nuts after drying is 4%. At the same time, the compound nuts are first treated with hot oil when shelling, and the temperature of the hot oil is 200°C, and then the The nuts in turn pass through the shelling machine. At the same time, the compound nuts need to be peeled after shelling, and the obviously polluted nuts, rotten fruits, insect-eaten fruits and fallen fruits are removed. After the sorting is completed, the size of the same type of nuts Uniform and consistent in color;

[0029] Step 2, crushing: mixing diffe...

Embodiment 2

[0035] Step 1, shelling: compound nuts include walnuts, hazelnuts, almonds, lotus seeds, cashew nuts and macadamia nuts, and the compound nuts are calculated by weight percentage, 3 parts of walnuts, 3 parts of hazelnuts, 5 parts of lotus seeds, 2 parts of cashew nuts and 4 parts of macadamia nuts , and the compound nuts need to be dried before processing, and the moisture content inside the compound nuts after drying is 3%. At the same time, the compound nuts are first treated with hot oil when shelling. Nuts with shells pass through the shelling machine in turn. At the same time, the compound nuts need to be peeled after shelling, and the obvious pollution, rotten fruit, insect-eaten fruit and fallen fruit are removed. After the sorting is completed, the same type of nuts Nuts are of uniform size and color;

[0036] Step 2. Crushing: Mix different types of nuts, then use a crushing device to preliminarily crush the mixed nuts, and finally mix the nuts screened out from the f...

Embodiment 3

[0042] Step 1, shelling: compound nuts include walnuts, hazelnuts, almonds, lotus seeds, cashew nuts and macadamia nuts, and the compound nuts are calculated by weight percentage, 5 parts of walnuts, 4 parts of hazelnuts, 2 parts of almonds, 3 parts of lotus seeds and 2 parts of cashews, In addition, the compound nuts need to be dried before processing, and the moisture content inside the compound nuts after drying is 3%. At the same time, the compound nuts are first treated with hot oil when shelling. The shelled nuts pass through the shelling machine in turn. At the same time, the compound nuts need to be peeled after shelling, and the obvious pollution, rotten fruit, insect-eaten fruit and fallen fruit are removed. After the sorting is completed, the same type of nuts Uniform size and consistent color;

[0043] Step 2. Crushing: Mix different types of nuts, and add the mixed nuts that have been sieved from the previous batch, and the content of the previous batch of nuts is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com