Sheet type binary structure heat-not-burn product

A heat-not-burn, binary structure technology, applied in the field of tobacco processing, can solve the problems of high flue gas temperature, complex production process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

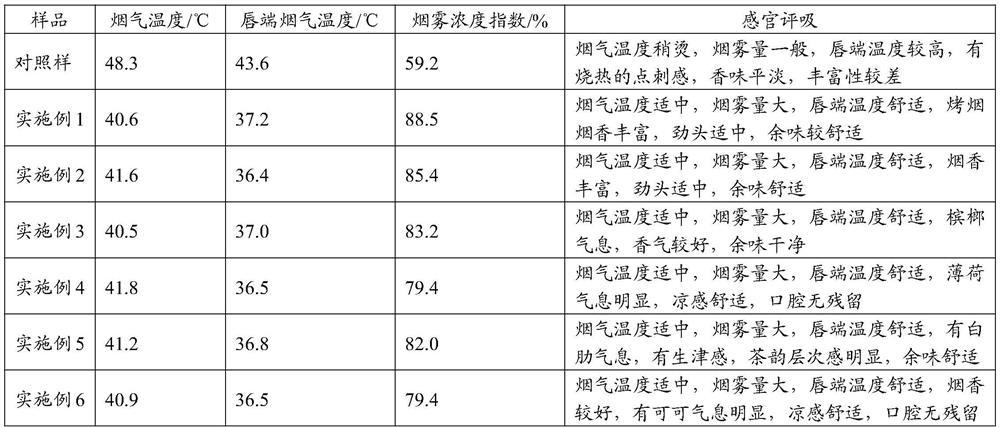

Examples

Embodiment 1

[0066] Example 1: Heat-not-burn product with sheet-type dual structure of the present invention

[0067] The implementation mode of this embodiment is as follows:

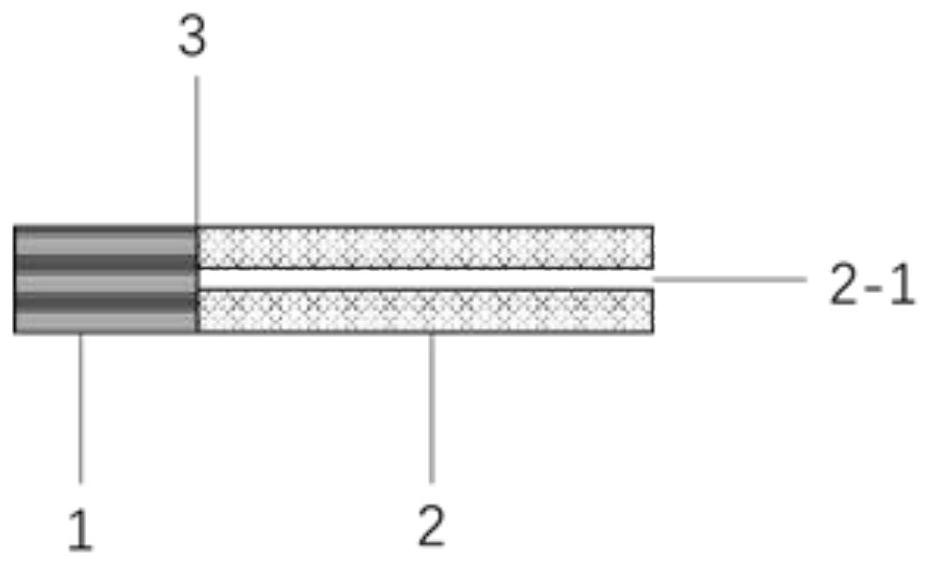

[0068] The sheet-type dual-structure heat-not-burn product is formed by wrapping a thin-sheet smoking section and a smoke confining section sequentially through an outer layer of wrapping paper, and the smoke confining section is a suction end.

[0069] Among them, the smoking material composed of 52 parts by weight of flue-cured tobacco plant raw materials, 26 parts by weight of glycerin smoking agent, 1.2 parts by weight of guar gum binder and 2.0 parts by weight of softwood fiber outer edge fiber is processed by the papermaking method described in the specification of this application Obtain a kind of strip smoking material, its grammage is 272g / m 2 , with a width of 2.1mm; the thin sheet smoking section is rolled from this strip-shaped smoking material, and its filling rate is 55%;

[0070] The smoke confinem...

Embodiment 2

[0074] Example 2: Heat-not-burn product with sheet-type dual structure of the present invention

[0075] The implementation mode of this embodiment is as follows:

[0076] The sheet-type dual-structure heat-not-burn product is formed by wrapping a thin-sheet smoking section and a smoke confining section sequentially through an outer layer of wrapping paper, and the smoke confining section is a suction end.

[0077] Among them, the smoking material composed of 68 parts by weight of air-dried tobacco plant raw materials, 10 parts by weight of propylene glycol smoke agent, 2.2 parts by weight of carboxymethyl cellulose binder and 2.8 parts by weight of hardwood fiber outer edge fiber is described in the specification of this application A strip-shaped smoking material is processed by the thick slurry method, and its grammage is 300g / m 2 , the width is 2.4mm; the thin sheet smoking section is rolled from this strip-shaped smoking material, and its filling rate is 65%;

[0078] T...

Embodiment 3

[0081] Embodiment 3: Heat-not-burn product with sheet-type dual structure of the present invention

[0082] The implementation mode of this embodiment is as follows:

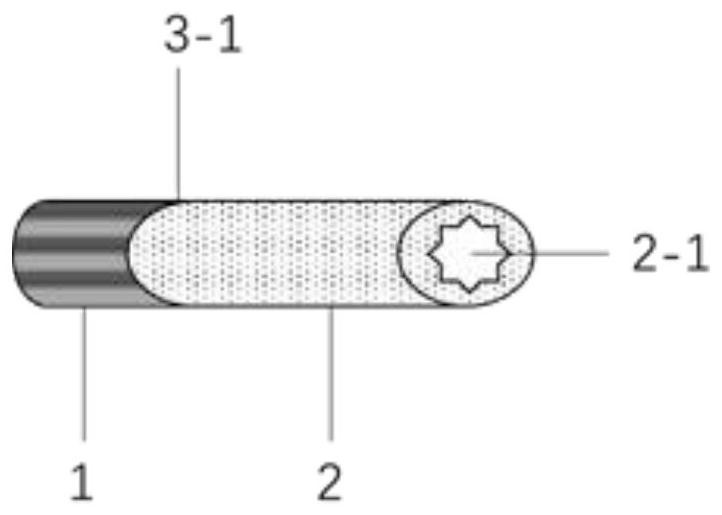

[0083] The sheet-type dual-structure heat-not-burn product is obtained by sequentially loading the sheet-type smoke-generating section and the smoke-binding section into a tube made of silica gel material with a temperature resistance higher than 300°C; the smoke-binding section is a suction end.

[0084] Among them, the smoking material composed of 40 parts by weight of betel nut plant raw materials, 12 parts by weight of glyceryl diacetate smoke agent, 0.8 parts by weight of chitosan adhesive and 3.6 parts by weight of hemp fiber outer edge fiber adopts the method described in the specification of this application. A strip-shaped smoking material is processed by rolling method, and its grammage is 179g / m2 , its width is 1.1 mm; the thin sheet smoking section is rolled from this strip-shaped smoking material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com