Electric automobile battery heat preservation structure

A technology for electric vehicles and batteries, applied in electric vehicles, secondary batteries, structural parts, etc., can solve problems such as the inability to ensure that the liquid-cooled water pipes are tightly attached, affect the heat preservation effect of the thermal insulation structure, and cannot be jacked up by the liquid-cooled water pipes, etc., to achieve Avoid heat transfer, save cost, improve overall strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

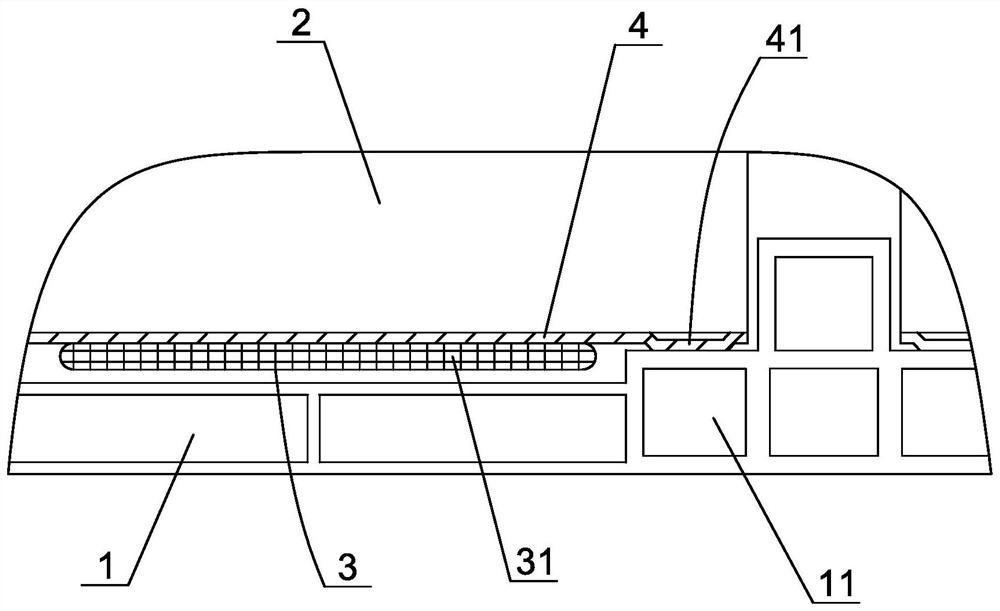

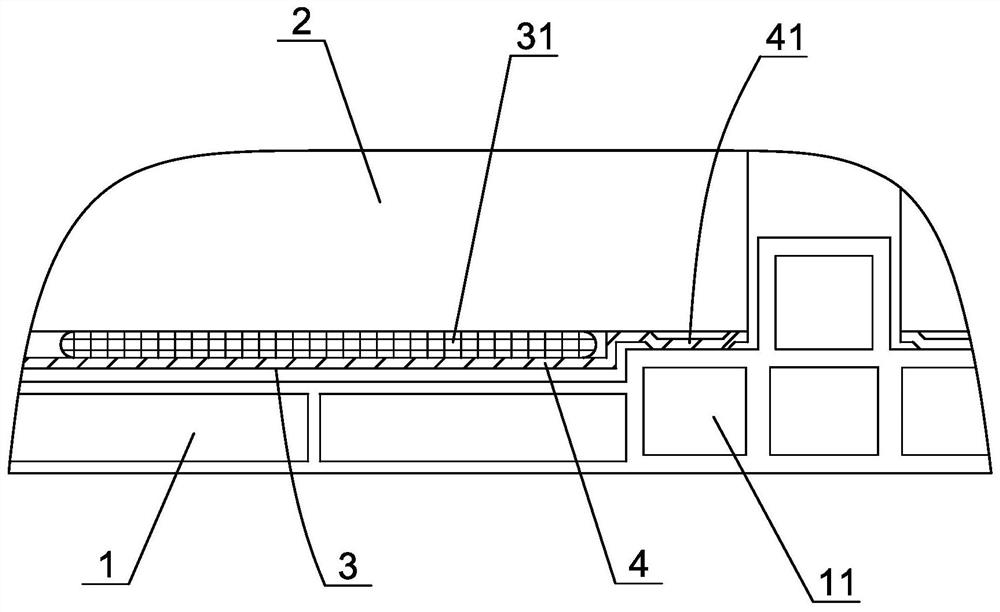

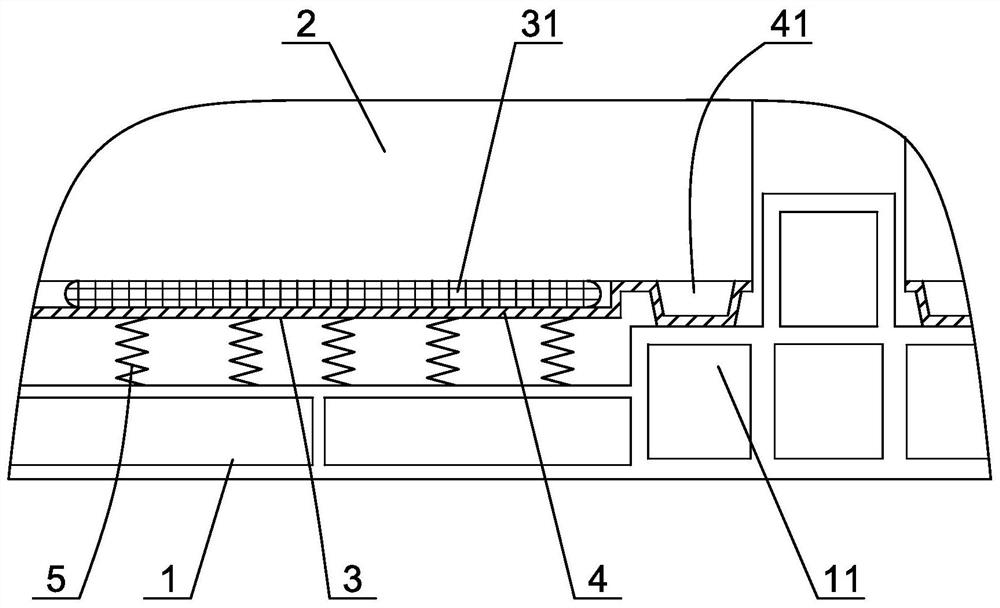

[0037] Such as figure 1 As shown, an electric vehicle battery insulation structure is mainly used for cooling or heating the lithium-ion battery of the electric vehicle, so that the battery can work within a suitable temperature range. Specifically, the battery includes an outer casing 1, a battery module 2 arranged inside the outer casing, a support beam 11 for supporting the battery module is provided on the bottom edge of the outer casing, and a liquid-cooled water pipe group 3 is arranged on the lower side of the battery module. The cold water pipe group includes liquid-cooled water pipes 31 arranged side by side and reinforcing members for improving the bending strength of the liquid-cooled water pipes. The liquid-cooled water pipes include a harmonica pipe in the middle and collectors connected to the front and rear ends of the harmonica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com