A folded graphene current collector and its preparation method and lithium-ion battery

A lithium-ion battery and current collector technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of limited contact area between current collectors and active materials, high current collector costs, and optimize battery costs. , The effect of improving rate performance and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] see Figure 5 , the invention provides a kind of preparation method of folded graphene current collector, described preparation method comprises the following steps:

[0041]1) Preparation of braided current collector: select a metal wire with a diameter of R and an aluminum foil with a length, width and height of m*n*h, weave and grow into a network structure with a width of b, and record it as the current collector X1; first make X1 Spray graphene solution on the surface, dry it, and record it as current collector X2; then pass X2 through the conductive fiber filament solution atomization area, and dry it to obtain current collector X3;

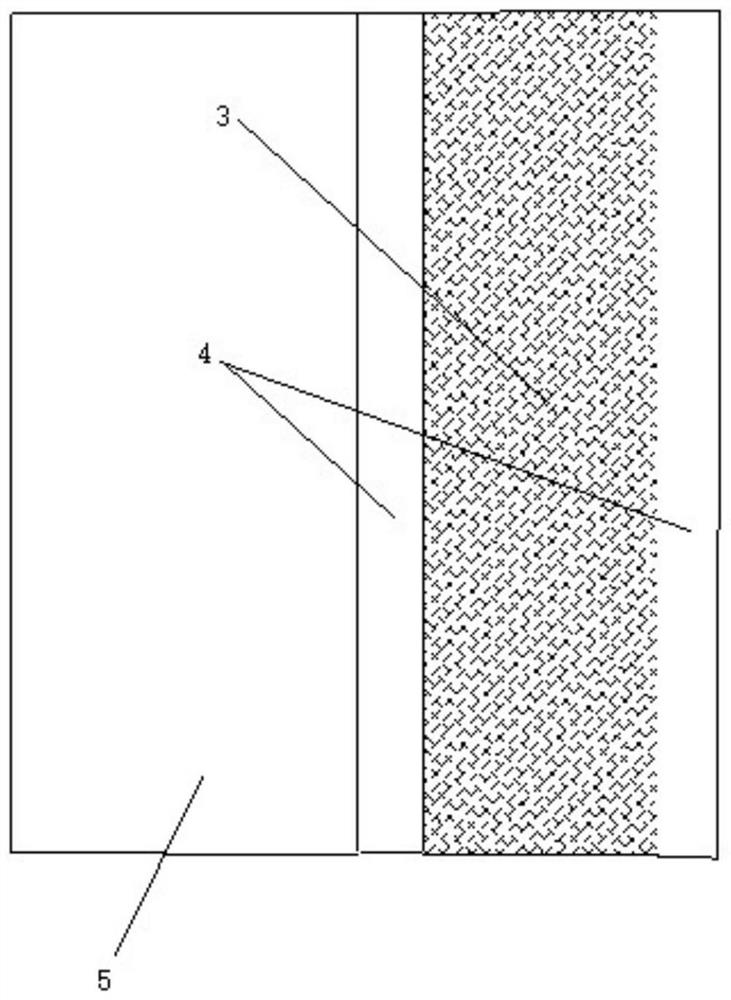

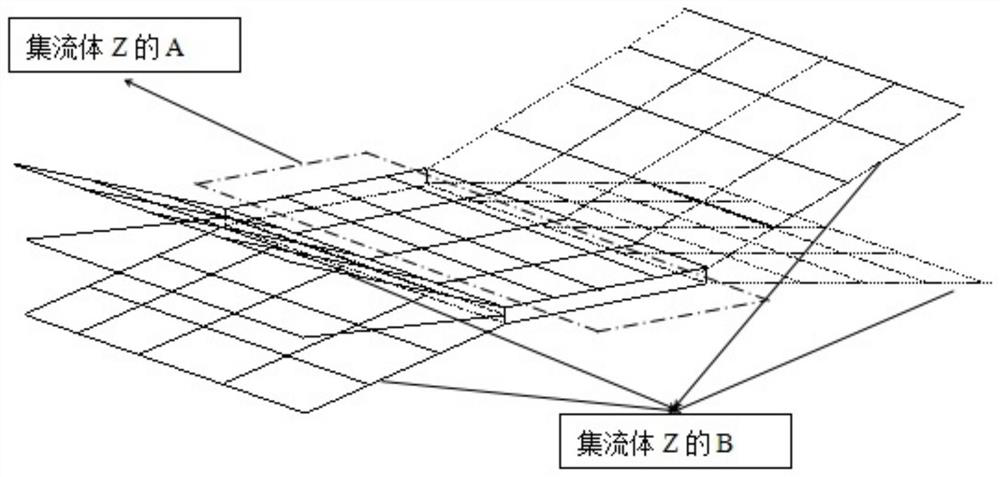

[0042] 2) Prepare a coated current collector, denoted as Y, wherein the coating is made of graphite; the non-woven part of X3 obtained in step 1) is combined with the non-coated part of Y by welding to obtain a foldable graphene current collector, It is recorded as Z; among them, Y is one layer, and the number of X3 layers is 1-100 ...

Embodiment 1

[0046] Choose a double-sided coated aluminum foil with a thickness of 0.02mm, a length of 100000mm, and a width of 300mm. The coating is graphite and the coating thickness is 0.0002mm. Choose the positive electrode LFP: (carbon black+graphene): PVDF=94: (1 +1): The positive electrode slurry prepared by 4 formulas is prepared into a positive electrode sheet with a length, width, and thickness of 150mm*150*0.2mm that can be assembled into a battery after coating, drying, rolling, and slicing; the selected thickness is 0.01mm, and the length is 100000mm, 305mm wide bare copper foil, choose negative electrode graphite: PVDF = 96: 4 negative electrode slurry, after coating, drying, rolling and slicing, etc., the length, width and thickness of the assembled battery are 152.5mm*152*0.15 mm negative pole piece; then assembled into a battery.

Embodiment 2

[0048] This embodiment provides a method for preparing a folded graphene current collector,

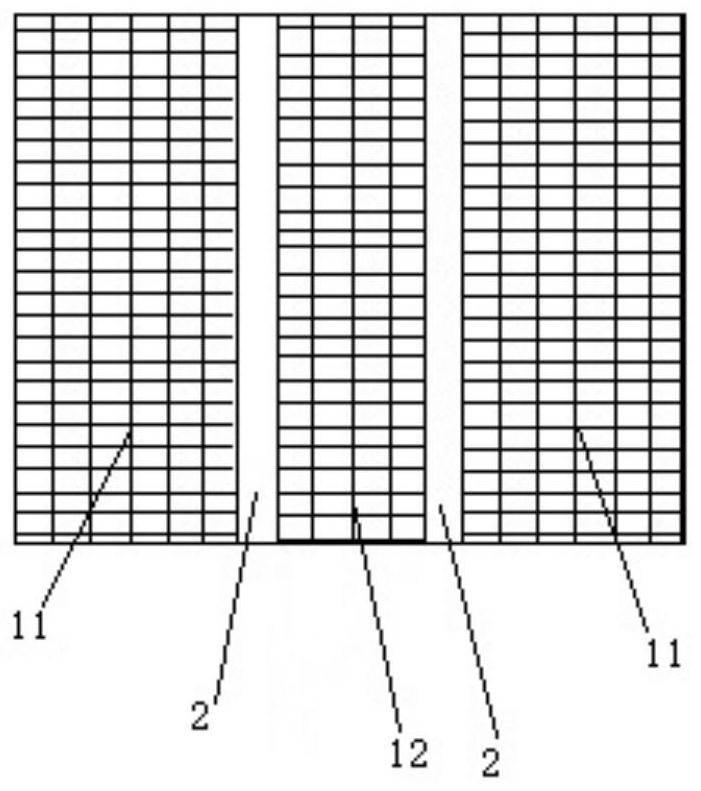

[0049] 1) Preparation of current collector X1: Select an aluminum wire with an R of 0.005mm and an aluminum foil with a length, width and height of 100000*10*0.005mm, such as Figure 7 As shown, weaving a current collector with a 0.02mm and b 0.02mm network structure with textile technology, the current collector is 100000mm long and 300mm wide;

[0050] 2) Preparation of current collector X3: select graphene slurry with a solid content of 5%, and spray it evenly on X1 with a spraying machine, wherein the non-woven part of X1 is not sprayed, and the sprayed current collector is dried in a drying tunnel to obtain Current collector X2, and then let X2 pass through the atomization area with 5% conductive fiber filament solution, so that the conductive fiber filaments are evenly distributed on the current collector X2, and then dry to obtain current collector X3, and wind X3; The length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com