Paper-based ethanol gas sensor

A gas sensor, ethanol technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of excessive energy consumption, high working temperature, weak stability, etc., to achieve the promotion of adsorption performance, high sensitivity, short response/recovery time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

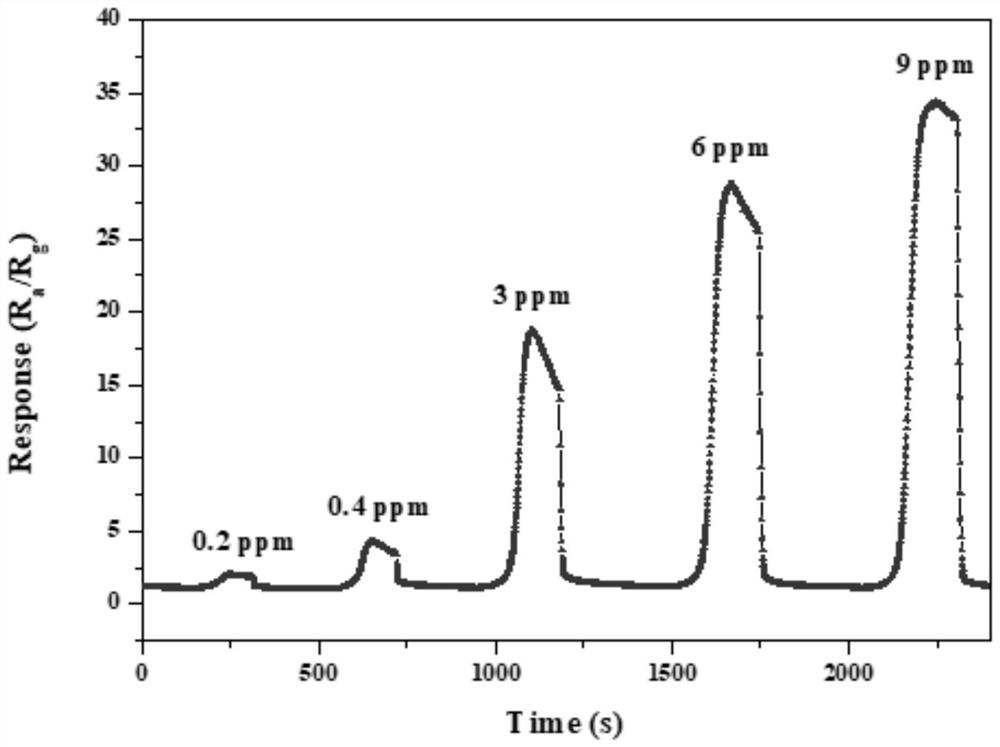

Embodiment 1

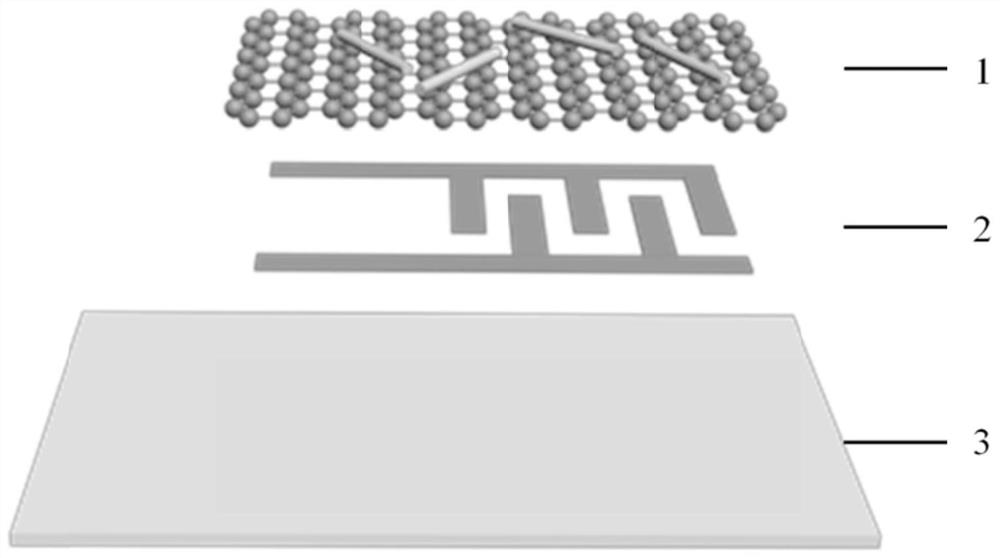

[0052] The preparation method of the paper-based ethanol gas sensor of this example comprises the following steps:

[0053] (1) Take a certain amount of zinc acetate and sodium hydroxide with a mass ratio of 1:4 and dissolve them in an equal amount of absolute ethanol, and ultrasonicate for 15 minutes to completely dissolve, then add the prepared sodium hydroxide solution dropwise to the zinc acetate solution , magnetically stirred for 30 minutes. Finally, the mixed solution was transferred to a reaction kettle to react at 180°C for 12 hours. After the reaction was completed, it was cooled to room temperature, washed by centrifugation, and dried at 60° C. for 24 hours to obtain white ZnO powder (zinc oxide nanorods).

[0054] (2) Ultrasonic the freeze-dried graphene oxide completely, and disperse it in distilled water at a mass ratio of 1:10 to obtain a graphene oxide dispersion solution. Then take 0.01g of ZnO powder prepared in step (1) and add 1mL of deionized water. Afte...

Embodiment 2

[0057] The preparation method of the paper-based ethanol gas sensor of this example comprises the following steps:

[0058] (1) Take a certain amount of zinc acetate and sodium hydroxide with a mass ratio of 1:4 and dissolve them in an equal amount of absolute ethanol, and ultrasonicate for 15 minutes to completely dissolve, then add the prepared sodium hydroxide solution dropwise to the zinc acetate solution , magnetically stirred for 30 minutes. Finally, the mixed solution was transferred to a reaction kettle to react at 180° C. for 16 hours. After the reaction was completed, it was cooled to room temperature, washed by centrifugation, and dried at 60° C. for 24 hours to obtain white ZnO powder (zinc oxide nanorods).

[0059] (2) Ultrasonic the freeze-dried graphene oxide completely, and disperse it in distilled water at a mass ratio of 1:10 to obtain a graphene oxide dispersion solution. Then take 0.01g of ZnO powder prepared in step (1) and add 1mL of deionized water. Af...

Embodiment 3

[0062] The preparation method of the paper-based ethanol gas sensor of this example comprises the following steps:

[0063] (1) Take a certain amount of zinc acetate and sodium hydroxide with a mass ratio of 1:4 and dissolve them in an equal amount of absolute ethanol, and ultrasonicate for 15 minutes to completely dissolve, then add the prepared sodium hydroxide solution dropwise to the zinc acetate solution , magnetically stirred for 30 minutes. Finally, the mixed solution was transferred to a reaction kettle to react at 180°C for 22 hours. After the reaction was completed, it was cooled to room temperature, washed by centrifugation, and dried at 60° C. for 24 hours to obtain white ZnO powder (zinc oxide nanorods).

[0064] (2) Ultrasonic the freeze-dried graphene oxide completely, and disperse it in distilled water at a mass ratio of 1:10 to obtain a graphene oxide dispersion solution. Then take 0.01g of ZnO powder prepared in step (1) and add 1mL of deionized water. Afte...

PUM

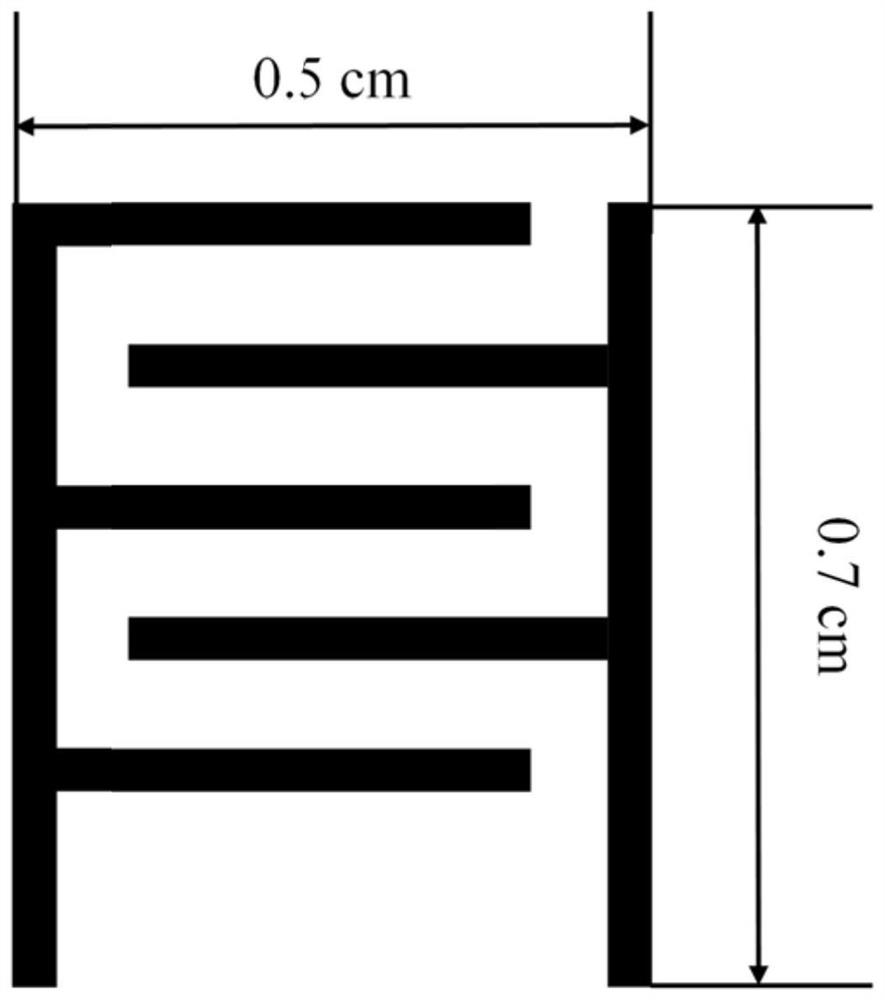

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com