A Phase Amplitude Analysis Method and Detection Device for Electromagnetic Detection of Oil Abrasive Particles

An oil abrasive particle and electromagnetic detection technology, which is applied in the direction of measuring devices, particle suspension analysis, suspension and porous material analysis, etc., can solve problems such as low precision, mixed metal components, complex devices, etc., and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

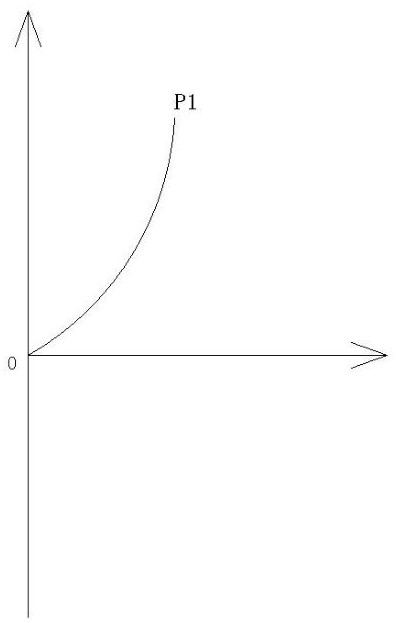

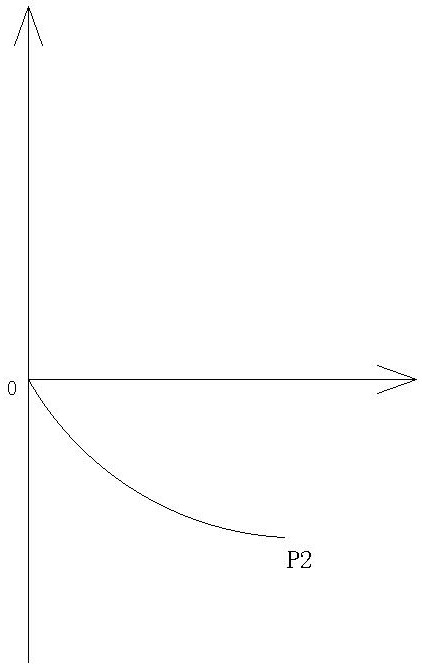

[0031] like Figures 1 to 4 As shown, a phase amplitude analysis method for electromagnetic detection of oil abrasive particles is used for the differential detection of ferromagnetic and non-ferromagnetic particles of oil liquid metal particles in pipelines in a hydraulic system. Including a detection device for detecting the concentration of metal particles in the oil, the specific steps are as follows:

[0032] a. Oil abrasive particle concentration detection: use the metal particle concentration detection device to detect the metal abrasive particle concentration in the oil pipeline;

[0033] b. Electromagnetic detection of oil abrasive particles: The impedance characteristic parameters of oil abrasive particles in the pipeline are detected by external electromagnetic detection coils;

[0034] c. Phase and amplitude analysis:

[0035] c1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com