A high-sensitivity hydraulic oil detection device and its manufacturing method

A high-sensitivity, detection device technology, applied in the direction of material capacitance, etc., can solve the problems of limitation, limited detection sensitivity of inductance method, limited detection flux of microfluidic chip, etc., and achieve the effect of improving throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

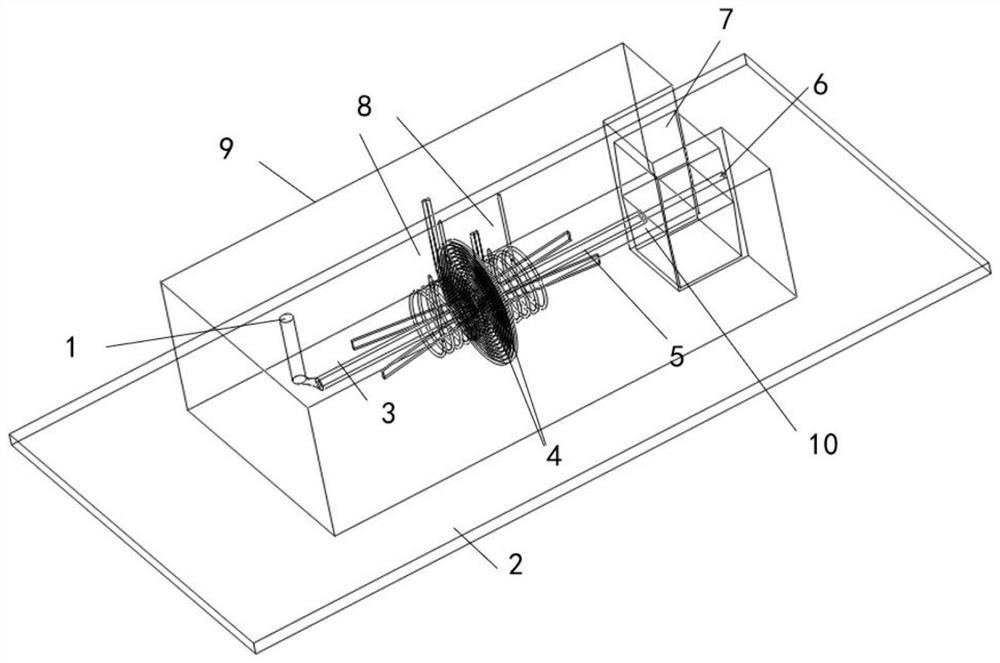

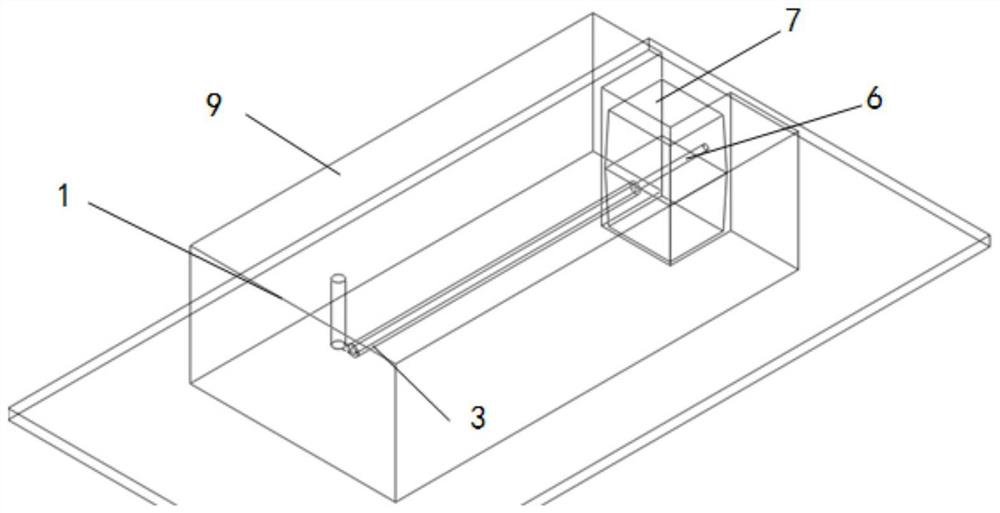

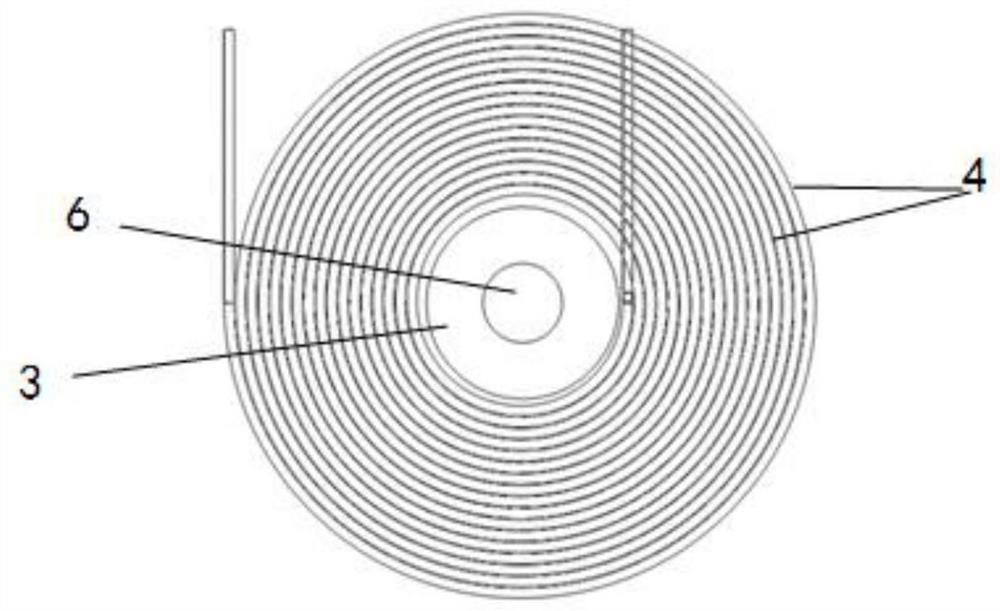

[0063] Such as Figure 7 As shown, the present invention provides a schematic diagram of a high-sensitivity hydraulic oil detection device in the inductance measurement mode. The four coils inside the device are connected in series. During the detection process, the four series coils are excited by high-frequency alternating current (1-2V, 0.1-2MHz) through the measurement unit, so that the solenoid coil 8 with the silicon steel sheet 5 inside produces a Exciting the magnetic field improves the detection sensitivity of the single-layer planar coil 4 . By detecting the voltage value (Vout) of the two single-layer planar coils 4 in the middle, the differential detection of ferromagnetic metal particles and non-ferromagnetic metal particle pollutants in the oil is realized.

Embodiment 2

[0065] Such as Figure 8 As shown, the present invention provides a schematic diagram of a high-sensitivity hydraulic oil detection device in capacitance measurement mode. The solenoid coils 8 on both sides of the device are respectively connected in series with the adjacent single-layer planar coils 4, and the two sets of coils are respectively excited by high-frequency alternating current (1-2V, 0.1-2MHz) through the measurement unit, and the edge effect of the capacitor plate is used It can measure the capacitance signal of the single-layer planar coil 4 in the middle. When the water droplets or air bubbles in the oil pass through the sensing module, due to the different dielectric constants, positive or negative capacitance signal pulses are generated. Through the change of the capacitance signal (Cp ) to realize the differential detection of water droplets and air bubbles in the oil.

[0066] Such as Figure 9 As shown, the present invention also provides a high-sensiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com