Gasification coupling low-NOx combustion system and method and design method

A combustion system and gasifier technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of expensive investment and operation costs, and achieve the effect of avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

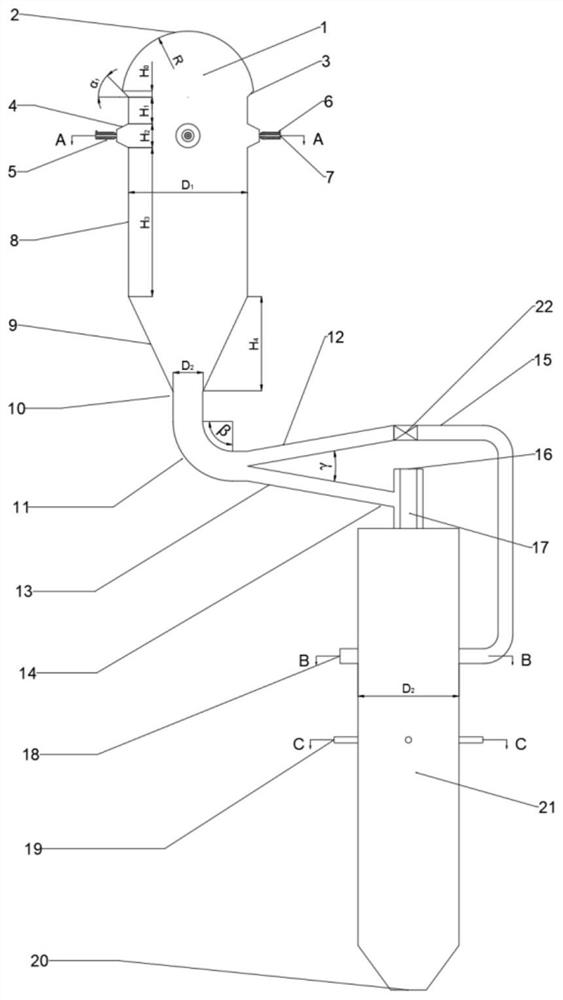

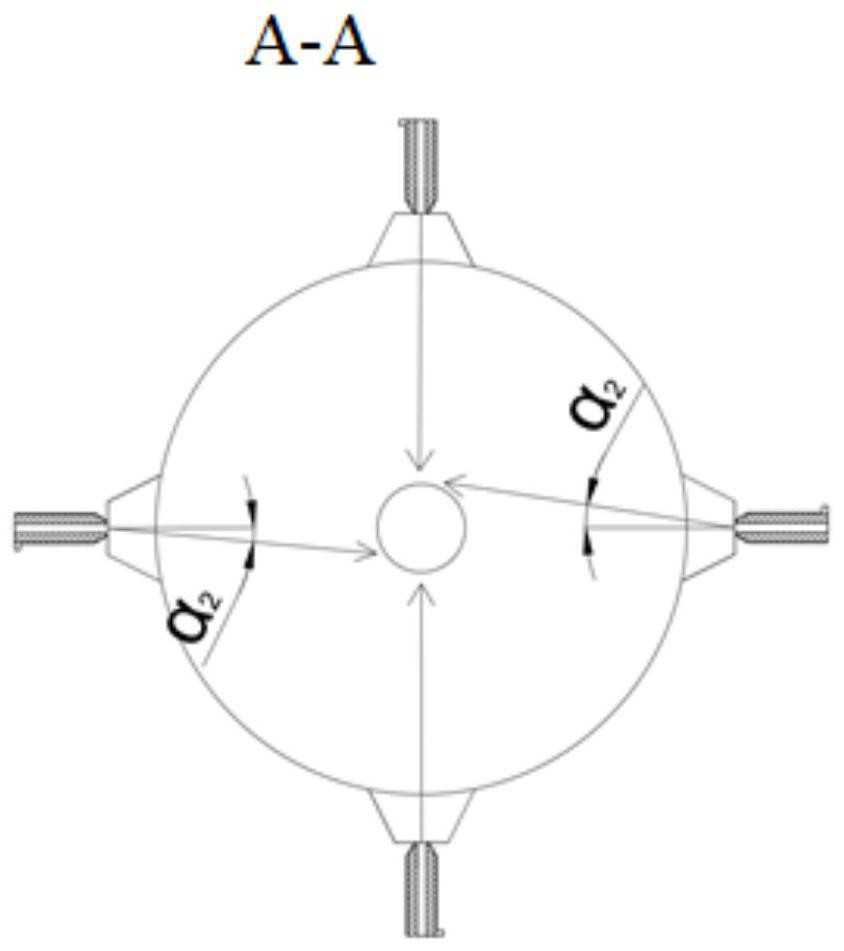

[0039] The entrained bed gasification technology is applied to the concept of pulverized coal decoupling combustion. The new semi-colliding and semi-tangential gasifier used in the present invention is a new type of gasifier suitable for decoupling pulverized coal combustion. Conventional industrial airflow In order to facilitate liquid slagging and obtain clean synthesis gas, bed gasifiers require that pulverized coal complete rapid pyrolysis, volatilization analysis, coke combustion and residual ash after gasification in the gasifier to be carried by the airflow as much as possible in the molten state. It is trapped on the wall of the gasification furnace, forming a liquid molten slag layer and flowing out of the gasification furnace. The gasifier used for pulverized coal decoupling combustion has pyrolysis product concentration separation equipment downstream, so the temperature of the gasifier should be controlled below the ash melting point to prevent clogging of the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com