Novel antibacterial and warm-keeping knitted velvet fabric and preparation method thereof

A new type of knitted fleece technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of heat loss, poor heat absorption, unsatisfactory warmth retention, etc., and achieve smooth fibers, good elasticity, and excellent antibacterial properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

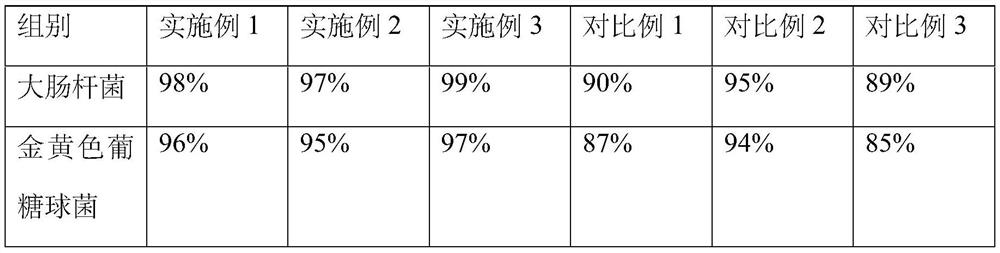

Examples

Embodiment 1

[0022] A new type of antibacterial warm knitted fleece fabric, comprising 35 parts by weight of volcanic rock fiber, 10 parts of soybean fiber, 70 parts of wool fiber, 1 part of bamboo charcoal viscose fiber, 10 parts of acrylic fiber, and 0.5 part of spandex fiber. The wool fiber has a fineness of 20 μm and a length of 50 mm.

[0023] The preparation method of described antibacterial warm knitted velvet novel fabric comprises the following steps:

[0024] S1. Dyeing process;

[0025] S2. Spinning process:

[0026] Add 0.5% environmentally friendly Stephenson and crude oil before combing to ensure that the oil content is 1.5%. The combing machine adopts the design process of 28mm small compartment, 10g / 2m through feeding, pre-spinning process, and controls the head needle off the machine Moisture regain 30%, the vehicle speed is 7000r / min, the winder is 800r / min, the tension disc is 90cN, the temperature is 20°C, and the humidity is 80%.

Embodiment 2

[0028] A new type of antibacterial warm knitted fleece fabric, comprising 20 parts by weight of volcanic rock fiber, 15 parts of soybean fiber, 40 parts of wool fiber, 5 parts of bamboo charcoal viscose fiber, 1 part of acrylic fiber and 3 parts of spandex fiber. The wool fiber has a fineness of 15 μm and a length of 70 mm.

[0029] The preparation method of described antibacterial warm knitted velvet novel fabric comprises the following steps:

[0030] S1. Dyeing process;

[0031] S2. Spinning process:

[0032] Add 2% environmentally friendly Stephenson and crude oil before combing to ensure that the oil content is 0.5%. The combing machine adopts the design process of 28mm small compartment, 10g / 2m through feeding, pre-spinning process, and controls the head needle off the machine Moisture regain 20%, the vehicle speed is 8000r / min, the winder is 700r / min, the tension disc is 110cN, the temperature is 30°C, and the humidity is 70%.

Embodiment 3

[0034] A new type of antibacterial warm knitted fleece fabric, comprising 27 parts by weight of volcanic rock fiber, 13 parts of soybean fiber, 50 parts of wool fiber, 2 parts of bamboo charcoal viscose fiber, 3 parts of acrylic fiber, and 0.8 part of spandex fiber. The wool fiber has a fineness of 18 μm and a length of 60 mm.

[0035] The preparation method of described antibacterial warm knitted velvet novel fabric comprises the following steps:

[0036] S1. Dyeing process;

[0037] S2. Spinning process:

[0038] Add 1% environmentally friendly Stephenson and crude oil before combing to ensure that the oil content is 1%. The combing machine adopts the design process of 28mm small compartment, 10g / 2m through feeding, pre-spinning process, and control of the head needle off the machine Moisture regain is 25%, the vehicle speed is 7500r / min, the winding is 750r / min, the tension disc is 100cN, the temperature is 25°C, and the humidity is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com