Preparation method of LaAlO3 nanofiber, product of preparation method and application of LaAlO3 nanofiber

A nanofiber and fiber technology, applied in the preparation of LaAlO3 nanofibers and its products and application fields, can solve the problems of unfriendly human body and environment, good chemical stability, long preparation time, etc., to improve electrochemical performance and cycle stability. Good performance, simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of LaAlO for supercapacitor 3 A method for preparing nanofibers, comprising the steps of:

[0030] a, 0.2916g of lanthanum nitrate and 0.2526g of aluminum nitrate were dissolved in 10g of DMF in turn, and then 1.65g of PVP was added thereto to obtain the required spinning solution for electrospinning;

[0031] b. Preparation of La(NO by electrospinning 3 ) 2 / Al(NO 3 ) 3 / PVP precursor fiber, the voltage is 18kV, the solution injection speed is 0.5ml / h, the spinning drum speed is 100r / min, the receiving distance is 20cm, and the electrospinning temperature is 25°C;

[0032] c, the resulting La(NO 3 ) 2 / Al(NO 3 ) 3 / After the PVP precursor fiber was dried at 80°C for 12h, in a box-type resistance furnace, the temperature was raised to 750°C at a heating rate of 5°C / min for sintering for 2h, and then cooled at a cooling rate of 1°C / min to obtain LaAlO 3 Nanofibers.

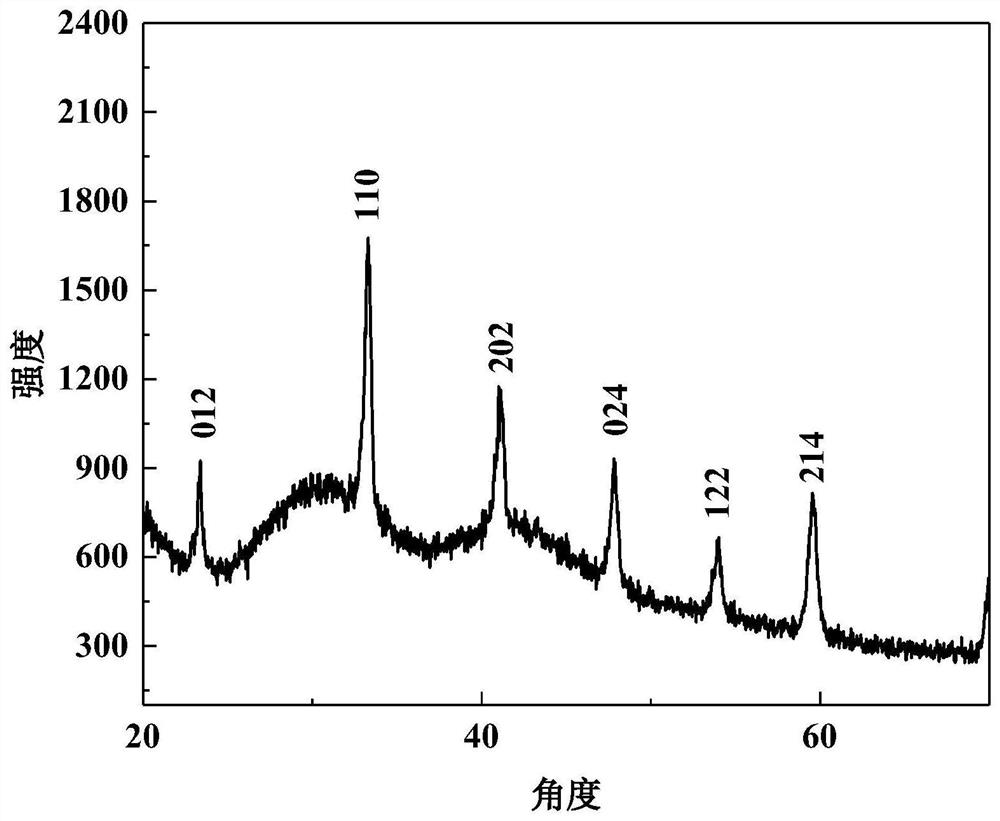

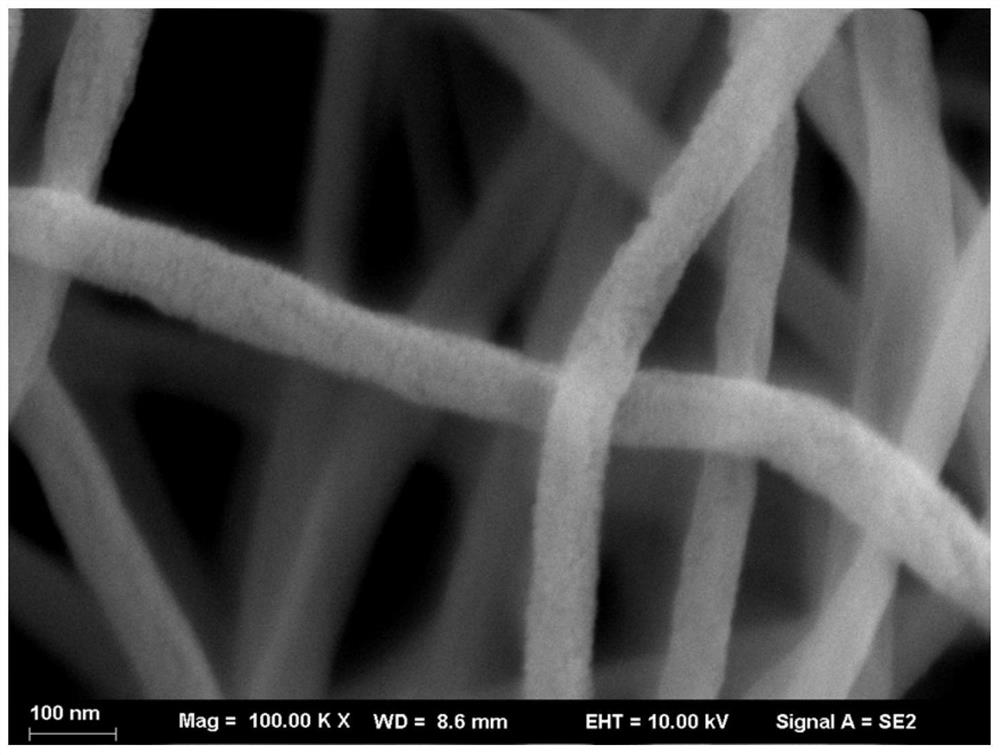

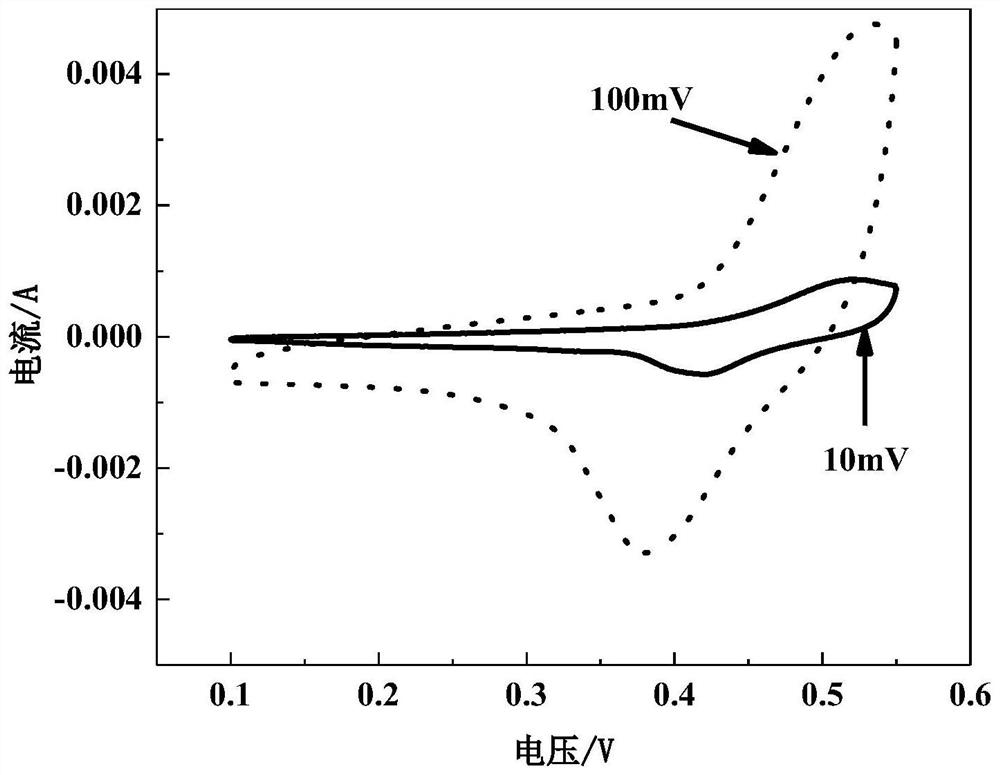

[0033] With the LaAlO that embodiment 1 makes 3 Nanofibers were tested by XRD, microsc...

Embodiment 2

[0035] A kind of LaAlO for supercapacitor 3 A method for preparing nanofibers, comprising the steps of:

[0036] a, 0.1458g of lanthanum nitrate and 0.1263g of aluminum nitrate were dissolved in 5g of DMF in turn, and then 0.825g of PVP was added thereto to obtain the required spinning solution for electrospinning;

[0037] b. Preparation of La(NO by electrospinning 3 ) 2 / Al(NO 3 ) 3 / PVP precursor fiber, the voltage is 10kV, the solution injection speed is 0.1ml / h, the spinning drum speed is 80r / min, the receiving distance is 5cm, and the electrospinning temperature is 0°C;

[0038] c, the resulting La(NO 3 ) 2 / Al(NO 3 ) 3 / After the PVP precursor fiber was dried at 50°C for 2h, in a box-type resistance furnace, the temperature was raised to 700°C at a heating rate of 0.5°C / min for sintering for 2h, and then cooled at a cooling rate of 0.5°C / min to obtain LaAlO 3 Nanofibers.

Embodiment 3

[0040] A kind of LaAlO for supercapacitor 3 A method for preparing nanofibers, comprising the steps of:

[0041] a, 0.4374g of lanthanum nitrate and 0.3789g of aluminum nitrate were dissolved in 15g of DMF in turn, and then 2.475g of PVP was added thereto to obtain the required spinning solution for electrospinning;

[0042] b. Preparation of La(NO by electrospinning 3 ) 2 / Al(NO 3 ) 3 / PVP precursor fiber, the voltage is 30kV, the solution injection speed is 0.6ml / h, the spinning speed is 300r / min, the receiving distance is 25cm, and the electrospinning temperature is 40°C;

[0043] c, the resulting La(NO 3 ) 2 / Al(NO 3 ) 3 / After the PVP precursor fiber was dried at 120°C for 24h, in a box-type resistance furnace, the temperature was raised to 850°C at a heating rate of 5°C / min for sintering for 4h, and then cooled at a cooling rate of 5°C / min to obtain LaAlO 3 Nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com