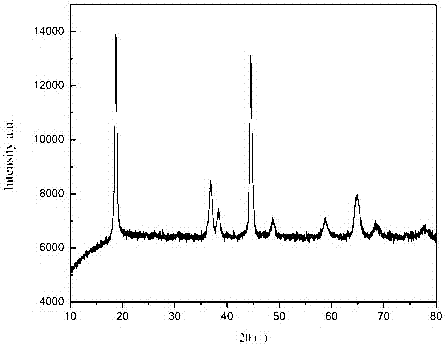

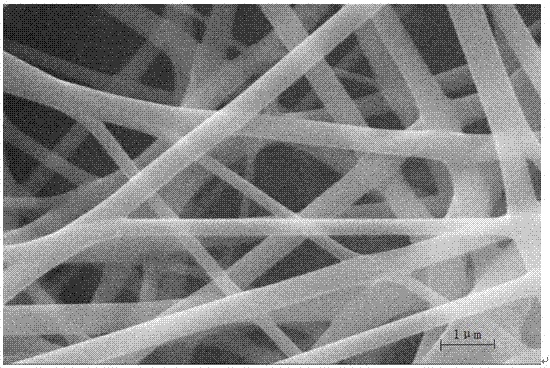

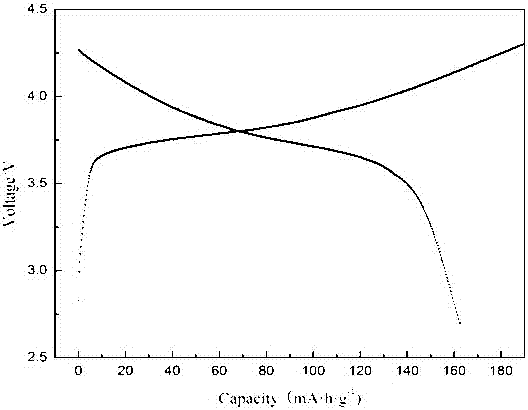

Preparation of lini by electrospinning 1/3 co 1/3 mn 1/3 o 2 fiber material method

An electrospinning, fiber material technology, applied in spinning solution preparation, fiber processing, filament/thread forming, etc., to achieve the effect of shallow embedded depth, good discharge performance, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of LiNi by Electrospinning 1 / 3 co 1 / 3 mn 1 / 3 o 2 A method for a fibrous material, comprising the steps of:

[0032] (1) Configuration of spinning solution: Measure 25ml of deionized water in a beaker, add polyvinylpyrrolidone (PVP) with a quality of 10% of water, then add 0.2mol of lithium carbonate, nickel nitrate, cobalt acetate and nitric acid Manganese, so that the concentration of Li element in the solution is 1.6mol / L, and the concentration of Ni, Co, and Mn elements is 0.8mol / L; when adding each time, ensure that the previously added substance is completely dissolved; keep stirring for 8h and then let it stand for 4h spinning solution;

[0033](2) Electrospinning: Electrospinning is carried out in an environment with a temperature of 20-25°C and a humidity of ≤30%. Add the spinning solution prepared in step (1) into the syringe, and the needle of the syringe is connected to the positive pole of the power supply. The receiving device is connected ...

Embodiment 2

[0036] Preparation of LiNi by Electrospinning 1 / 3 co 1 / 3 mn 1 / 3 o 2 A method for a fibrous material, comprising the steps of:

[0037] (1) Configuration of spinning solution: Measure 25ml of deionized water in a beaker, add polyvinylpyrrolidone (PVP) with a mass of 10% of water, then add 0.2mol of lithium acetate, nickel acetate, cobalt nitrate and acetic acid Manganese, so that the concentration of Li element in the solution is 1.6mol / L, and the concentration of Ni, Co, and Mn elements is 0.8mol / L; when adding each time, ensure that the previously added substance is completely dissolved; keep stirring for 8h and then let it stand for 4h spinning solution;

[0038] (2) Electrospinning: Electrospinning is carried out in an environment with a temperature of 20-25°C and a humidity of ≤30%. Add the spinning solution prepared in step (1) into the syringe, and the needle of the syringe is connected to the positive pole of the power supply. The receiving device is connected to t...

Embodiment 3

[0041] Preparation of LiNi by Electrospinning 1 / 3 co 1 / 3 mn 1 / 3 o 2 A method for a fibrous material, comprising the steps of:

[0042] (1) Configuration of spinning solution: Measure 25ml of deionized water in a beaker, add polyvinylpyrrolidone (PVP) whose quality is 10% of water, then add 0.2mol of lithium hydroxide, nickel carbonate, cobalt carbonate and Manganese carbonate, so that the concentration of the Li element in the solution is 1.6mol / L, and the concentration of Ni, Co, and Mn elements is 0.8mol / L; when adding each time, ensure that the previously added substance is completely dissolved; keep stirring for 8 hours and then let it stand 4h to get spinning solution;

[0043] (2) Electrospinning: Electrospinning is carried out in an environment with a temperature of 20-25°C and a humidity of ≤30%. Add the spinning solution prepared in step (1) into the syringe, and the needle of the syringe is connected to the positive pole of the power supply. The receiving device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com