A top-blown oxygen lance, a vanadium-extracting top-bottom double-blowing method, and a vanadium-extracting smelting method

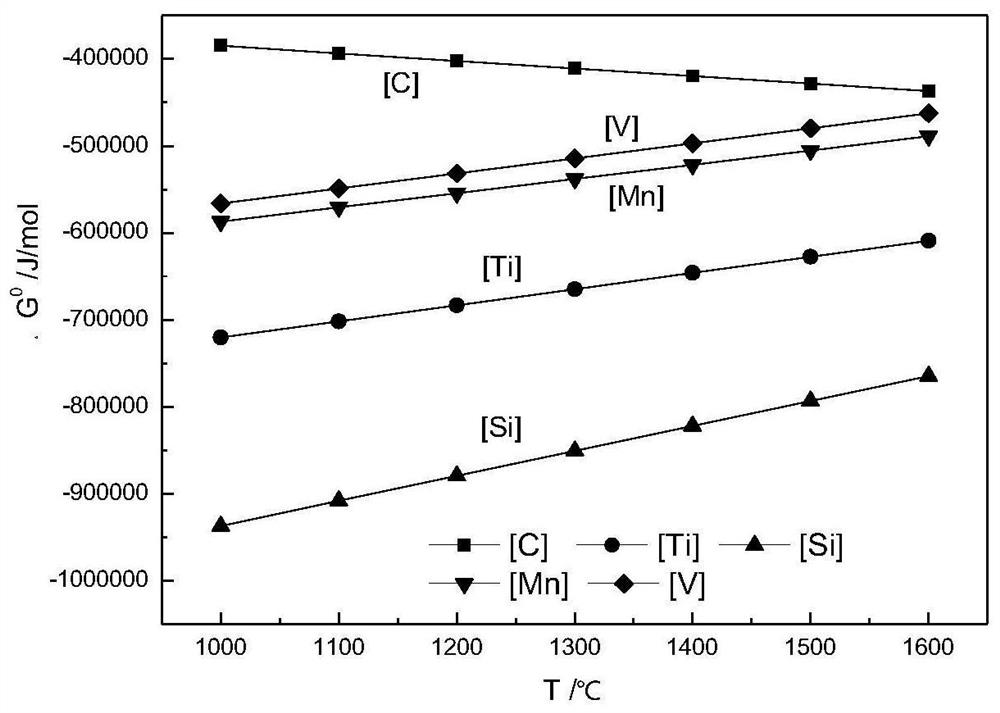

A smelting method and top-blowing oxygen lance technology are applied in the field of vanadium-extracting top-bottom re-blowing method and vanadium-extracting smelting, top-blowing oxygen lance, and can solve the problem of low oxidation rate of vanadium in molten iron, high residual vanadium content in semi-steel, and metallic iron. The problem of high content, to achieve the effect of improving oxidation efficiency, improving fluidity, and improving oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] This implementation involves a top-blown oxygen lance, a vanadium-extracting top-bottom double-blowing method, and a vanadium-extracting smelting method:

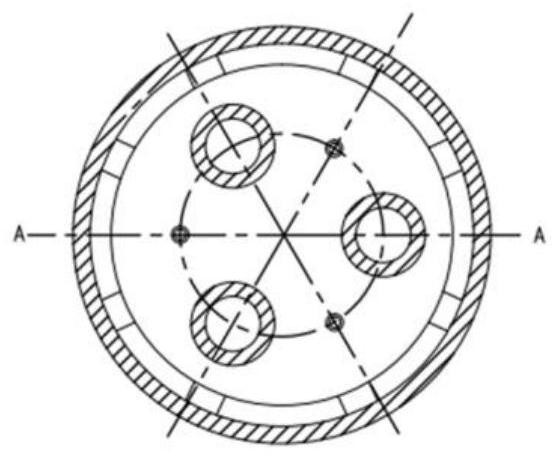

[0083] The mass percentage of the chemical composition of the vanadium-containing molten iron: C 4.11%, Si 0.23%, Mn 0.19%, P 0.11%, S 0.10%, Ti 0.11%, V 0.31%. A porous oxygen lance is adopted, which has an oxygen lance structure with three main injection holes and three auxiliary holes, and its structural schematic diagram is shown in Figure 2. The main hole of the oxygen lance has 3 holes with a diameter of 40mm and a Mach number of 2.01. Around the main hole are arranged 3 auxiliary holes with a diameter of 8mm and a Mach number of 1.

[0084] Vanadium extraction top and bottom blowing method: 0-120 seconds, the oxygen flow rate is controlled at 2.2Nm 3 / min, the position of the oxygen lance is 0.85m, and the flow rate of the bottom blowing is 0.03Nm 3 / min; 121-260 seconds, the oxygen flow rate is 1.5Nm 3 / mi...

Embodiment 2

[0088] This implementation involves a top-blown oxygen lance, a vanadium-extracting top-bottom double-blowing method, and a vanadium-extracting smelting method:

[0089] The chemical composition of vanadium-containing molten iron is calculated by mass percentage: C 4.15%, Si 0.26%, Mn 0.21%, P 0.12%, S 0.11%, Ti 0.12%, V 0.33%. A porous oxygen lance is adopted, with an oxygen lance structure of three main nozzle holes and six auxiliary holes, and its structural schematic diagram is shown in Fig. 3 . The main hole of the oxygen lance has 3 holes with a diameter of 45mm and a Mach number of 1.99. Around the main hole are arranged 6 auxiliary holes with a diameter of 10mm and a Mach number of 1.

[0090] Vanadium extraction top and bottom blowing method: 0-120 seconds, the oxygen flow rate is controlled at 2.3Nm 3 / min, the position of the oxygen lance is 0.9m, and the flow rate of the bottom blowing is 0.04Nm 3 / min; 121-260 seconds, the oxygen flow rate is 1.9Nm 3 / min, oxyg...

Embodiment 3

[0094] This implementation involves a top-blown oxygen lance, a vanadium-extracting top-bottom double-blowing method, and a vanadium-extracting smelting method:

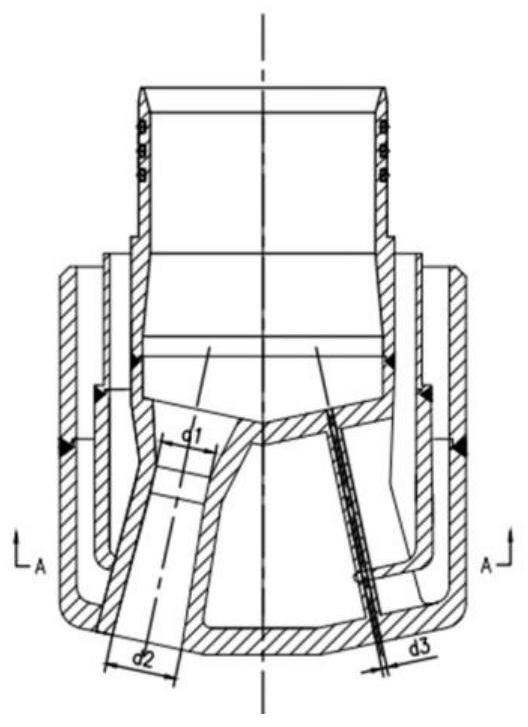

[0095] The chemical composition of vanadium-containing molten iron is calculated by mass percentage: C 4.14%, Si 0.24%, Mn 0.19%, P 0.10%, S 0.11%, Ti 0.13%, V 0.33%. A porous oxygen lance is adopted, which has an oxygen lance structure with four main nozzle holes and four auxiliary holes, and its structural schematic diagram is shown in Figure 4. The main hole of the oxygen lance has 4 holes with a diameter of 50 mm and a Mach number of 1.99. Around the main hole are arranged 4 auxiliary holes with a diameter of 12 mm and a Mach number of 1.

[0096] Vanadium extraction top and bottom blowing method: 0-120 seconds, the oxygen flow rate is controlled at 2.5Nm 3 / min, the position of the oxygen lance is 0.8m, and the flow rate of the bottom blowing is 0.04Nm 3 / min; 121-260 seconds, the oxygen flow rate is 1.2Nm 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com