Microbial self-repairing concrete and preparation method thereof

A self-healing, concrete technology, applied in the field of concrete, can solve the problems of inapplicability, aerobic alkaliphilic microbial activity and easy limitation of repair ability, etc., to achieve the effect of improving stability, improving repair effect, and promoting repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

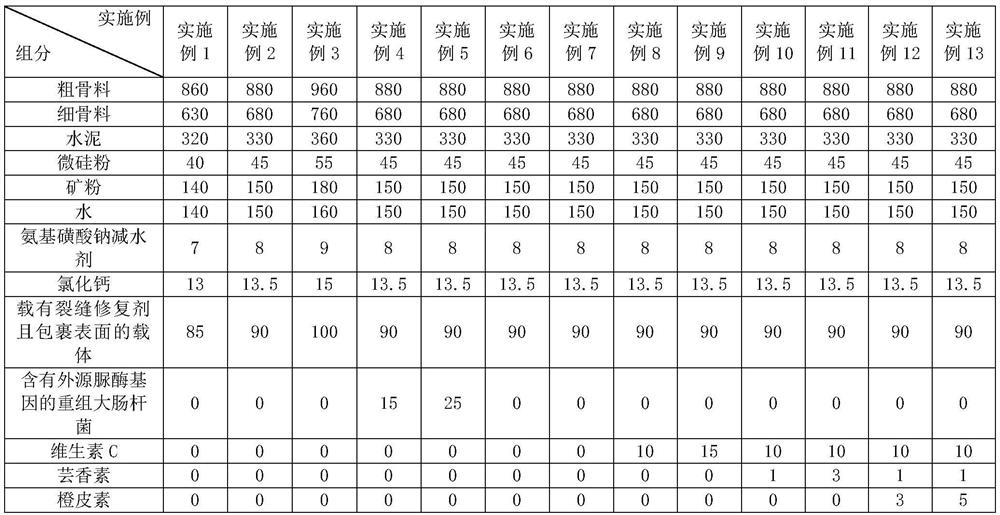

Examples

preparation example 1

[0047] A method for preparing a carrier carrying a crack repair agent and wrapping the surface, comprising the following steps:

[0048] S1. Add 5.2 g of peptone, 3.1 g of beef extract, 0.43 g of sodium bicarbonate, and 0.51 g of sodium carbonate to 1 L of distilled water in sequence, then adjust the pH to 9.5 with 1 mol / L sodium carbonate solution, and sterilize at 110°C for 45 minutes. , get the culture medium;

[0049] S2. Inoculate Bacillus pasteuri with anaerobic alkalophilic properties and the ability to synthesize carbonate with lactate as a matrix, and then put the culture medium into a constant temperature shaker, and at 28°C, Under the rotating speed of 115r / min, culture at a constant temperature for 24h to obtain a Bacillus pasteuri bacteria liquid;

[0050] S3, after the urea that accounts for 11 parts of concrete overall weight parts is added in the Bacillus Pasteurella bacterial liquid, with distilled water, the Bacillus Pasteurella bacterial liquid is diluted t...

preparation example 2

[0054] A method for preparing a carrier carrying a crack repairing agent and wrapping its surface, the difference from Preparation Example 1 is that: in step S2, Bacillus corii with aerobic and alkalophilic properties is inoculated into the culture medium, and then the cultured The base was placed in a constant temperature shaker, and incubated at a constant temperature of 28° C. at a rotational speed of 115 r / min for 24 hours to obtain a Bacillus pasteurian bacteria liquid.

preparation example 3

[0056] A method for preparing a carrier carrying a crack repairing agent and wrapping the surface is different from Preparation Example 1 in that: in step S3, after adding 11.5 parts by weight of urea to the Bacillus pasteuri bacteria liquid, the method is used in step S3. Dilute the Bacillus Pasteurella bacteria solution with distilled water to an OD600 value of 0.3 to obtain a Bacillus Pasteurella diluted bacteria solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com