Machining process of high-temperature-resistant anti-loosening bolt

A processing technology and anti-loosening technology, which is applied in the direction of bolts, threaded products, manufacturing tools, etc., can solve the problems of unreliable vibration, small bolt tightening torque, and easy loosening, so as to improve hardness and eliminate internal Stress, the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A processing technology for high temperature resistant and anti-loosening bolts, comprising the following steps:

[0041] S1. Select austenitic stainless steel as raw material, and make corresponding blanks according to product specifications;

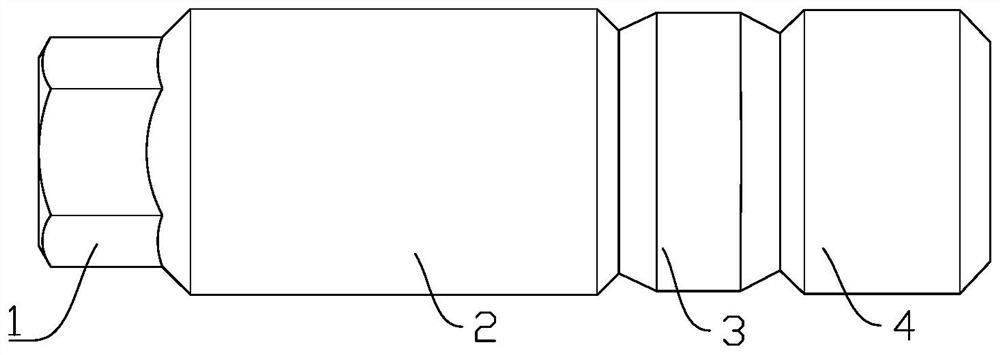

[0042] S2, cold heading out four sections of blanks of different sizes, which are respectively the head 1, the first thread section section 2, the connecting section 3, and the second thread section section 4;

[0043] S3, upsetting the head 1 of the blank into a hexagonal shape;

[0044] S4, cleaning to remove the surface dirt produced by cold heading;

[0045] S5, perform solution treatment on the blank;

[0046] S6, aging treatment of the blank;

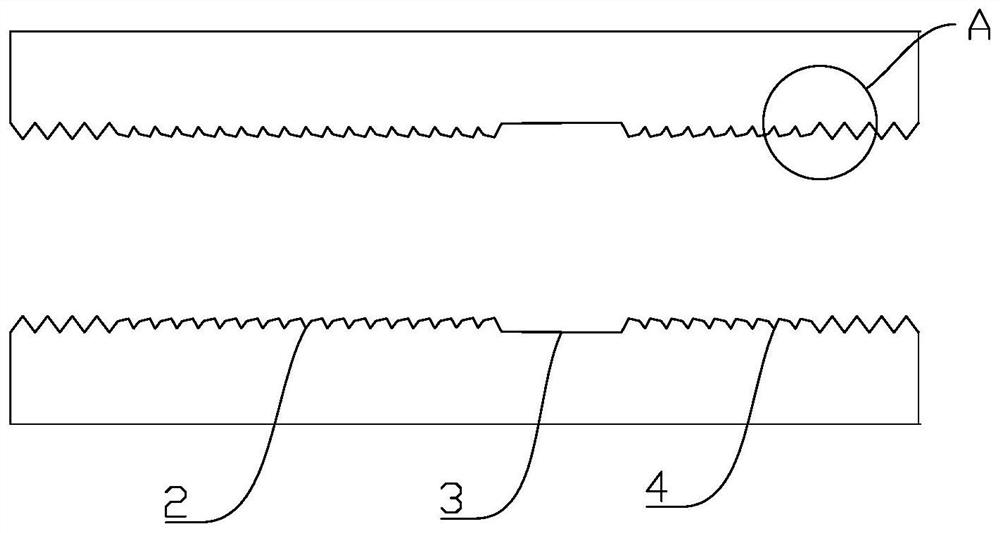

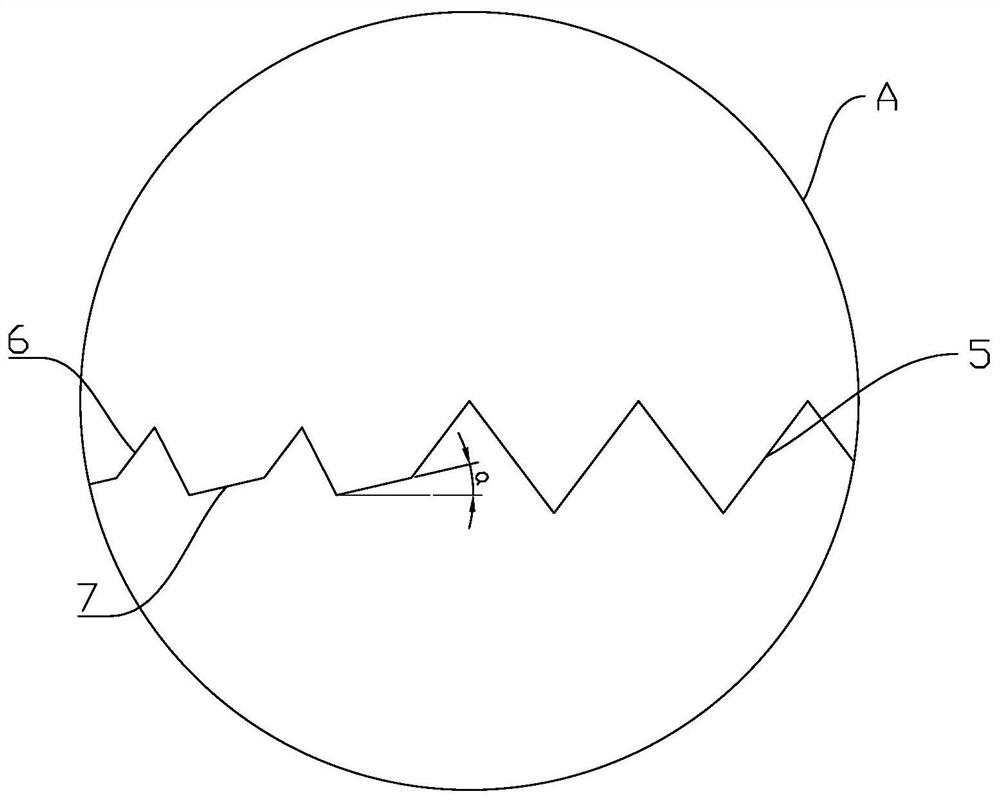

[0047] S7, using a thread rolling machine, for the first thread section section 2 and the second thread section section 4, both the standard thread 5 and the anti-loosening thread 6 are rolled out at one time;

[0048] S8. Carry out a special numerical test of effective torque o...

Embodiment 2

[0057] A processing technology for high temperature resistant and anti-loosening bolts, comprising the following steps:

[0058] S1. Select austenitic stainless steel as raw material, and make corresponding blanks according to product specifications;

[0059] S2, cold heading out four sections of blanks of different sizes, which are respectively the head 1, the first thread section section 2, the connecting section 3, and the second thread section section 4;

[0060] S3, upsetting the head 1 of the blank into a hexagonal shape;

[0061] S4, cleaning to remove the surface dirt produced by cold heading;

[0062] S5, perform solution treatment on the blank;

[0063]S6, aging treatment of the blank;

[0064] S7, using a thread rolling machine, for the first thread section section 2 and the second thread section section 4, both the standard thread 5 and the anti-loosening thread 6 are rolled out at one time;

[0065] S8. Carry out a special numerical test of effective torque on...

Embodiment 3

[0074] A processing technology for high temperature resistant and anti-loosening bolts, comprising the following steps:

[0075] S1. Select austenitic stainless steel as raw material, and make corresponding blanks according to product specifications;

[0076] S2, cold heading out four sections of blanks of different sizes, which are respectively the head 1, the first thread section section 2, the connecting section 3, and the second thread section section 4;

[0077] S3, upsetting the head 1 of the blank into a hexagonal shape;

[0078] S4, cleaning to remove the surface dirt produced by cold heading;

[0079] S5, perform solution treatment on the blank;

[0080] S6, aging treatment of the blank;

[0081] S7, using a thread rolling machine, for the first thread section section 2 and the second thread section section 4, both the standard thread 5 and the anti-loosening thread 6 are rolled out at one time;

[0082] S8. Carry out a special numerical test of effective torque o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thread height | aaaaa | aaaaa |

| Thread height | aaaaa | aaaaa |

| Thread height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com