Bending forming die for medium-thickness pore plate U-shaped part of asymmetric pore channel structure

A channel structure, bending forming technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult manufacturing process of the first wall, and achieve the effect of preventing misalignment and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

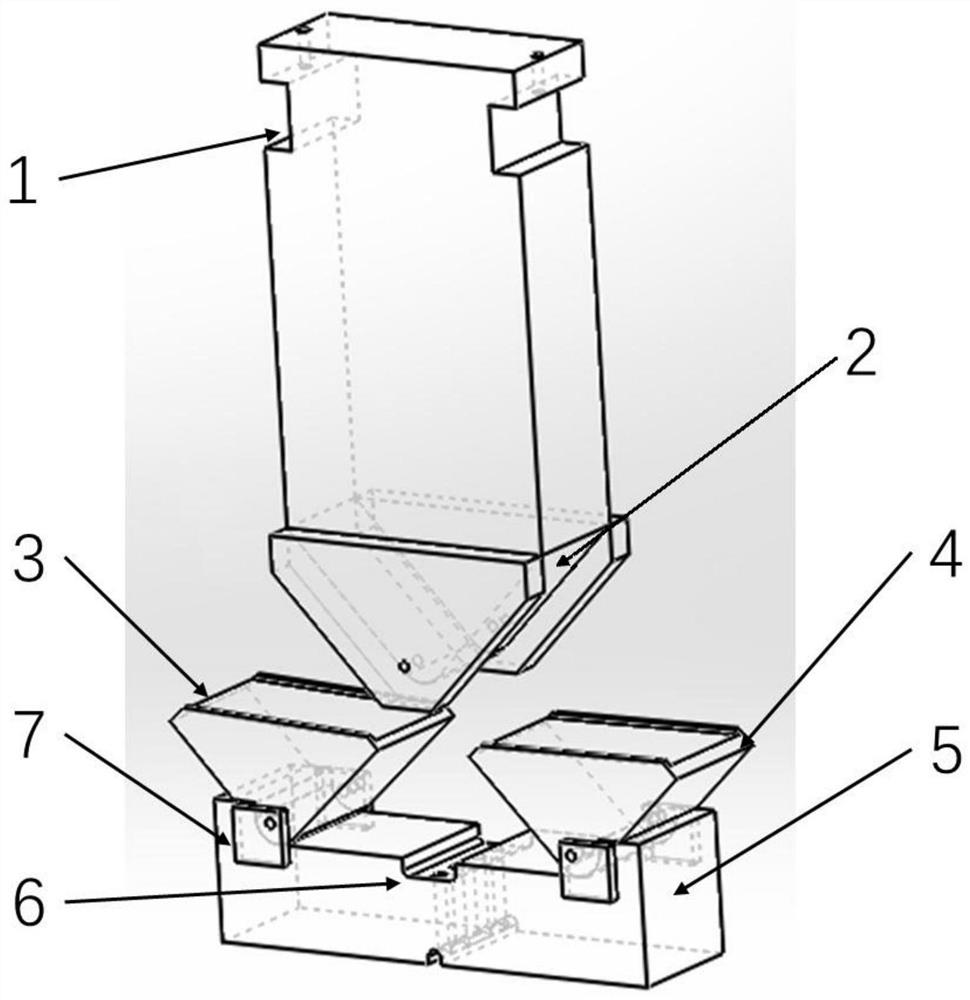

[0033] like figure 1 As shown, the present invention provides a kind of bending forming mold for medium-thick orifice plate U-shaped parts with asymmetric channel structure, including T-shaped force transmission part 1, bending pressure head 2, first rotatable support part 3, second rotatable support part 4 and the die 5; the die 5 is provided with a groove 6, one end of the die 5 is connected to the first rotatable support 3, and the other end of the second rotatable support 4 is connected to the second rotatable support 4 . Wherein, the first rotatable support member 3 and the second rotatable support member 4 are respectively provided with downward slideway grooves, and the lower end of the T-shaped force transmission member 1 is equipped with a bending indenter 2, and the bending indenter 2 and the groove 6 Matching, when the bending head 2 moves down to the groove 6 through the T-shaped force transmission part 1 through the groove of the down slideway, the medium-thick o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com