Method for selectively plating inner blind hole of ultrathin plate

A technology of plating and blind hole selection, applied in the field of PCB manufacturing, can solve the problems of enlarged blind hole sag value and board size deformation, and achieve the effect of reducing rework rate, ensuring product quality, and ensuring accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

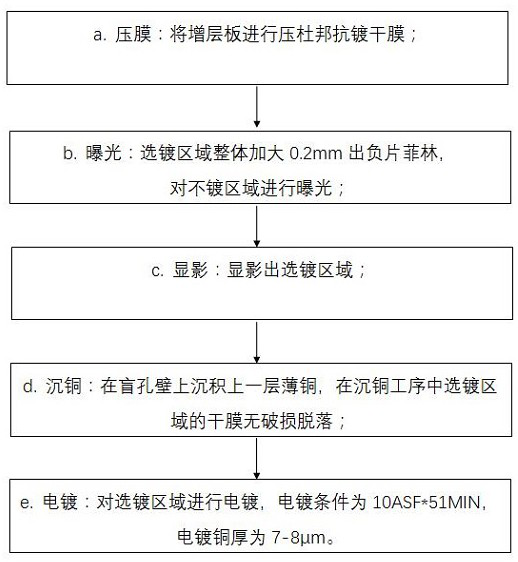

[0027] A method for selective plating of blind holes in the inner layer of an ultra-thin plate is completed according to the following steps:

[0028] a. Film pressing: press the build-up board with DuPont anti-plating dry film;

[0029] b. Exposure: The blind hole point and the area that accepts the blind hole point are used as the selective plating area, and the rest of the area is used as the non-plating area. The selective plating area is enlarged by 0.2mm as a whole, and the negative film is released, and it is placed under the irradiation of a purple light to undergo polymerization. Cross-linking reaction, exposure to unplated areas;

[0030] c. Developing: develop the selected plating area;

[0031] d. Copper sinking: use chemical methods to depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com