Induction heating device and strip steel pickling system

An induction heating device and induction heating technology, applied in the direction of induction heating devices, induction heating, electric heating devices, etc., can solve problems such as difficulty in achieving scale removal effect, affecting the recovery and utilization of scale resources, and rising temperature of scale, and achieve improvement Pickling effect, ensuring high-speed and stable operation, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

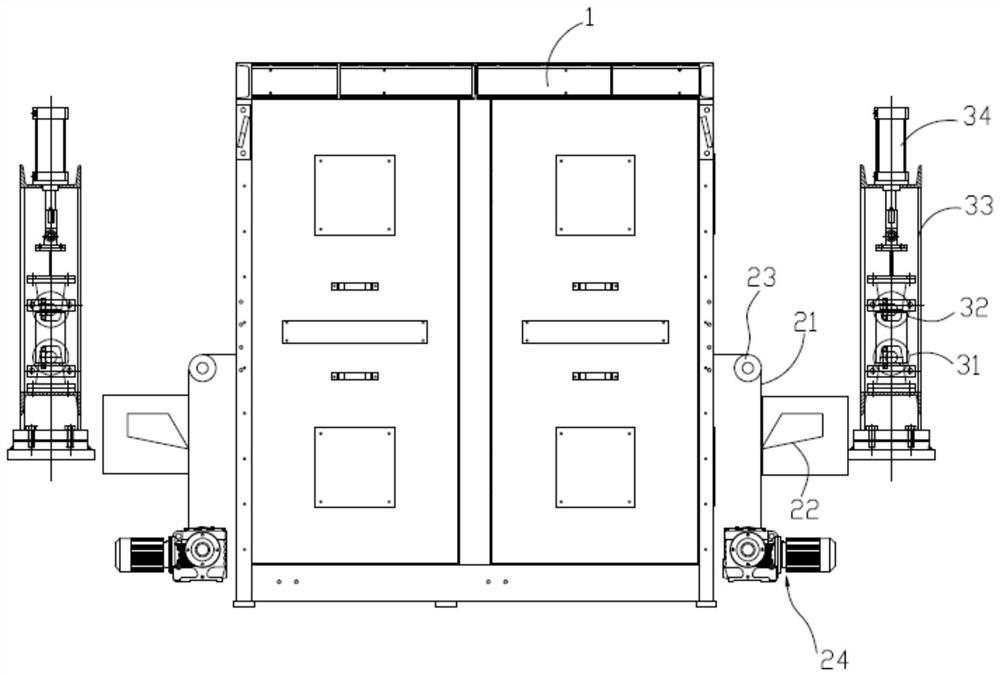

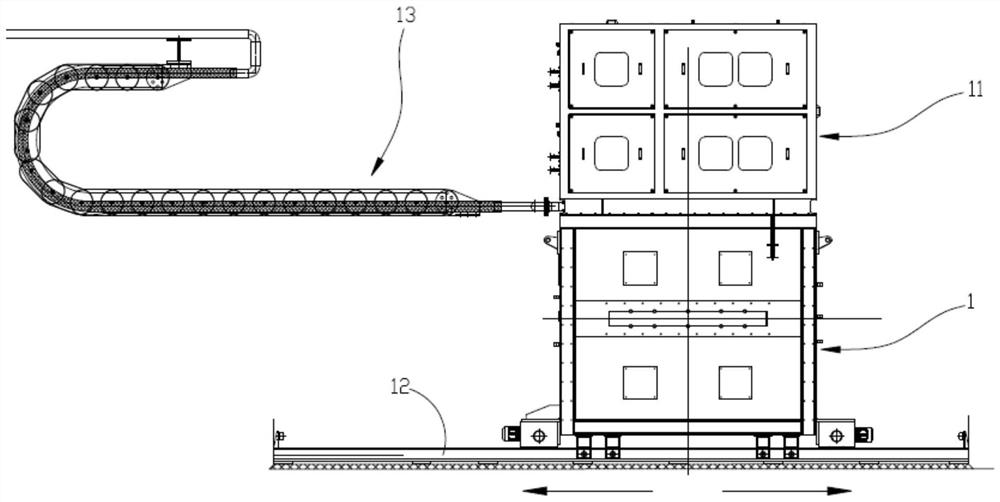

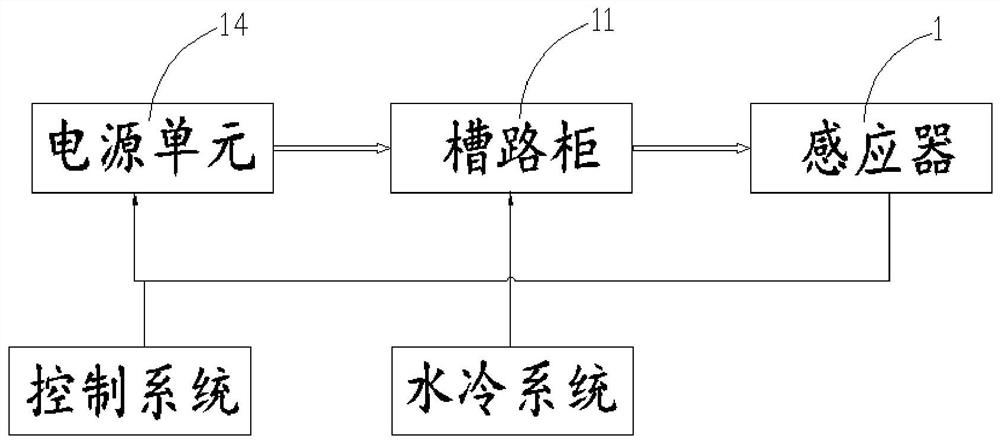

[0025] Such as figure 1 , the embodiment of the present invention provides an induction heating device, including an inductor 1, the inductor 1 has an induction heating chamber, a strip steel inlet and a strip steel outlet, the strip steel inlet and the strip steel outlet are both connected to the The induction heating chamber is connected and arranged on both sides of the induction heating chamber so as to define a strip steel running channel, and also includes a belt conveyor. The belt moving path of the belt conveyor includes a material receiving section, and in the material receiving section, the belt 21 passes through the induction heating chamber and is located directly below the strip running channel.

[0026] The above-mentioned inductor 1 can adopt an existing induction heating device suitable for heating strip steel, for example, a conventional longitudinal magnetic induction heating device in the field. In one of the embodiments, the inductor 1 is in the form of a ...

Embodiment 2

[0038] An embodiment of the present invention provides a strip pickling system, including a strip pickling device, and the induction heating device provided in the first embodiment above is arranged upstream of the strip pickling device.

[0039] The rapid heating of strip steel before pickling can be realized by the above-mentioned induction heating device, which can significantly improve the effect of subsequent pickling, shorten the pickling time, and save the energy required for heating the acid solution. , The pickling time can be shortened by about 1 / 3, so the length of the pickling line can be shortened accordingly, reducing investment costs and production costs. For high-grade strip steel, in winter and other low-temperature environments, it can quickly supplement the heat of the strip under limited space conditions to ensure high-speed and stable operation of the production line and avoid slow-down production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com