Preparation method of friction nano-generator and friction nano-generator

A technology of nano generator and friction layer, applied in the direction of friction generator, etc., which can solve problems such as wear, excessive stretching, and long repair time of self-repairing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

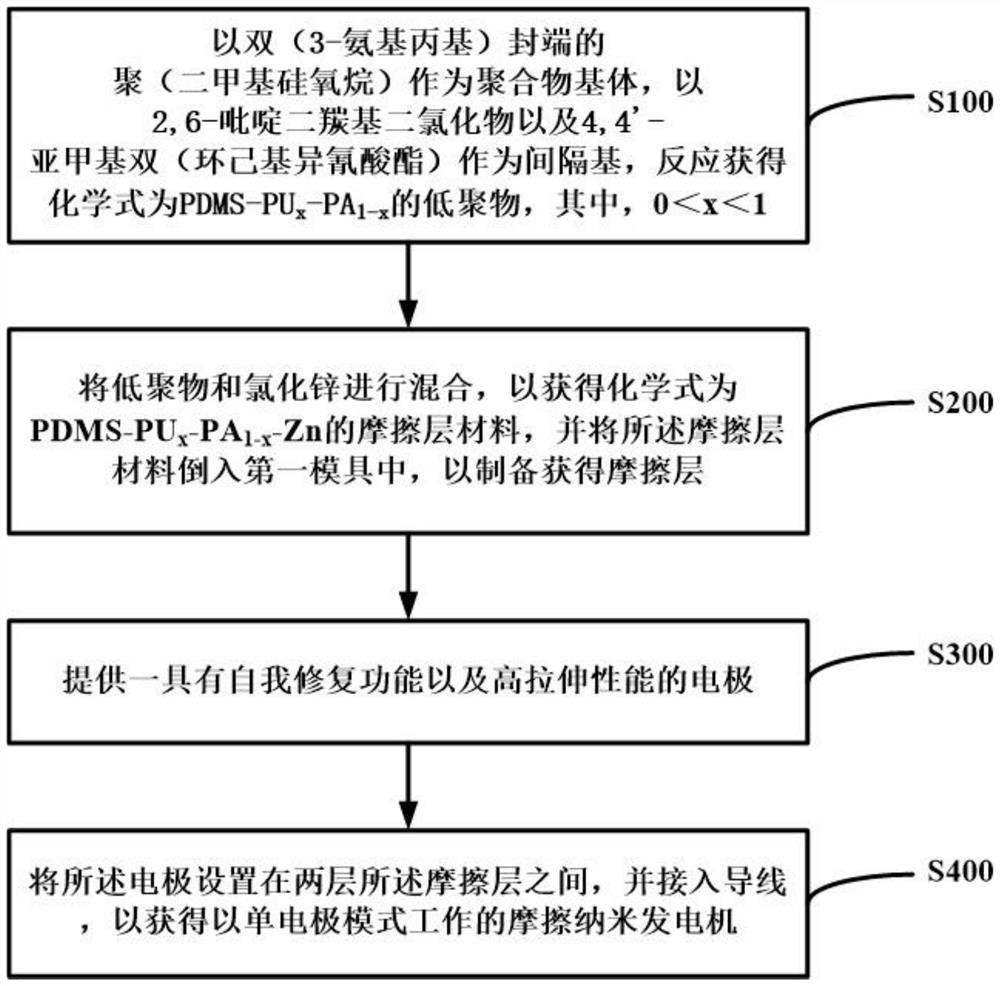

[0073] figure 1 A schematic structural diagram showing a method for preparing a triboelectric nanogenerator according to an embodiment of the present invention. Such as figure 1 Shown, this preparation method comprises:

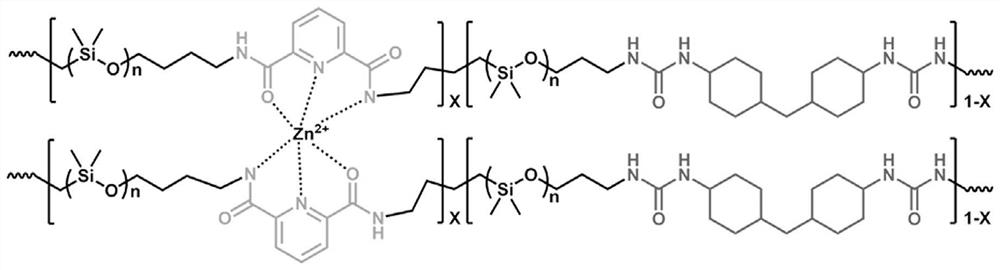

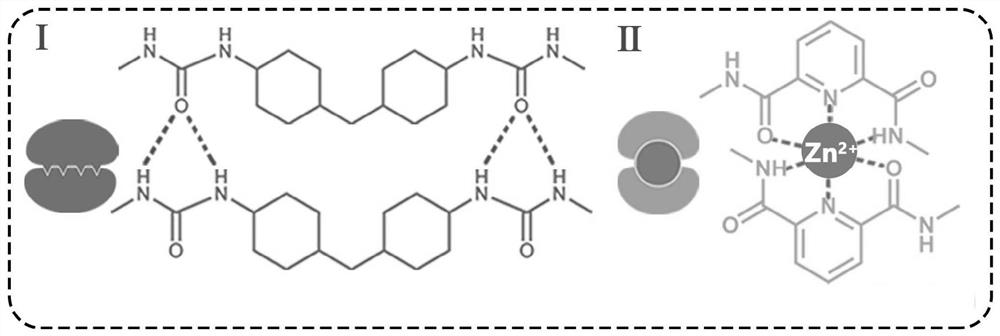

[0074] Step S100, using bis(3-aminopropyl)-terminated poly(dimethylsiloxane) as a polymer matrix, and 2,6-pyridinedicarbonyl dichloride and 4,4'-methylenebis( Cyclohexyl isocyanate) as a spacer, the reaction obtained chemical formula is PDMS-PU x -PA 1-x The oligomer of , wherein, 0<x<1;

[0075] Step S200, mixing the oligomer and zinc chloride to obtain the chemical formula PDMS-PU x -PA 1-x - Zn friction layer material, and pouring the friction layer material into the first mold to prepare and obtain the friction layer;

[0076] Step S300, providing an electrode with self-healing function and high stretchability;

[0077] Step S400, disposing the electrode between the two friction layers, and connecting wires, so as to obtain a triboelectric nanogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com