Bionic gradient super-hydrophobic structure design method based on Marangoni effect

A structure design, super-hydrophobic technology, applied in design optimization/simulation, nanotechnology for materials and surface science, special data processing applications, etc., can solve the uncontrollable dynamic behavior of droplets on the surface of super-hydrophobic structures, which cannot be effectively Realize the directional movement of droplets and the self-cleaning of the automatic rolling surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

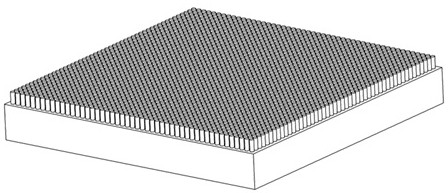

[0050] Embodiment 1: Cylindrical array structure

[0051] The roughness factor r and the solid area fraction f in the composite interface:

[0052]

[0053] Let the period interval be The aspect ratio is

[0054] Substitute r and f into the Wenzel model formula:

[0055]

[0056] Substitute r and f into the Cassie model formula:

[0057]

Embodiment 2

[0058] Embodiment 2: square column array structure

[0059] The roughness factor r and the solid area fraction f in the composite interface:

[0060]

[0061] Let the period interval be The aspect ratio is

[0062] Substitute r and f into the Wenzel model formula:

[0063]

[0064] Substitute r and f into the Cassie model formula:

[0065]

Embodiment 3

[0066] Embodiment 3: Parabolic rotation array structure

[0067] Let the equation of the parabola be y=ax 2 +b(a<0)

[0068] Because the height of the parabolic rotating structure is H and the diameter is D, so b=H

[0069]

[0070] When the droplet is in Cassie state in contact with the solid surface, the bottom of the droplet is in contact with the top part of the parabolic rotating structure, and the contact depth h′ is determined by the intrinsic contact angle θ between the droplet and the solid e depends.

[0071] Since the size of the droplet is much larger than the size of the parabolic rotating structure, its bottom can be regarded as a straight line in myopia, and the solid-liquid contact can also be regarded as a small paraboloid with a base radius of a' and a height of h'.

[0072] Since y=ax 2 +b, so at the solid-liquid interface there are:

[0073]

[0074] Combine the above two formulas to get:

[0075] So the area of the small paraboloid is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com