Wetting device for textile cloth

A wetting technology for textile cloth, which is applied in the field of textile wetting devices for textiles, and can solve problems such as uneven wetting process and flow reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

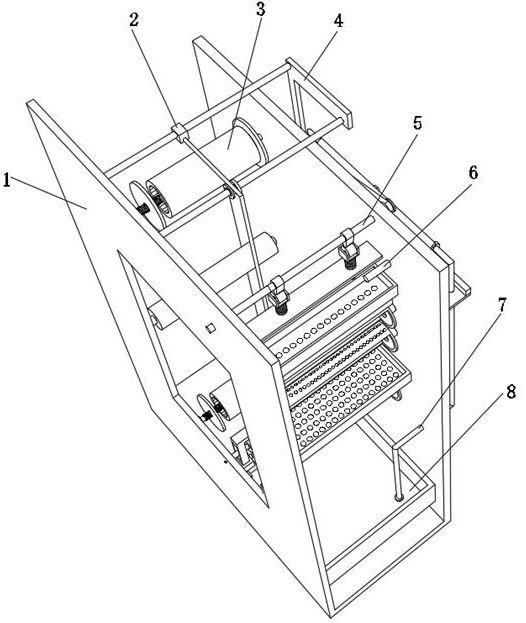

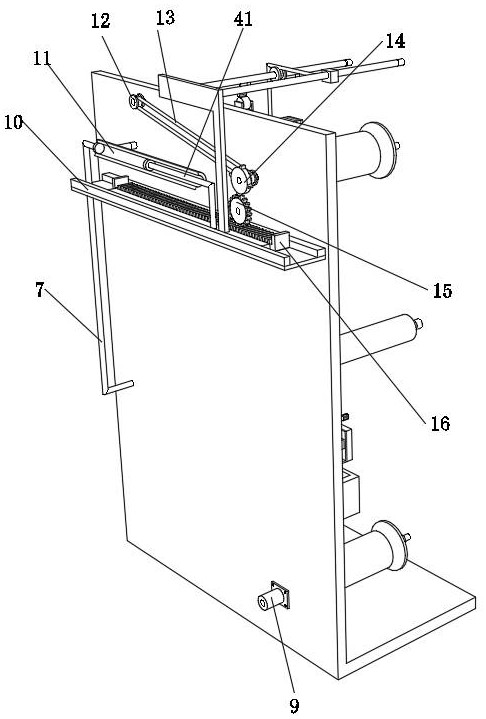

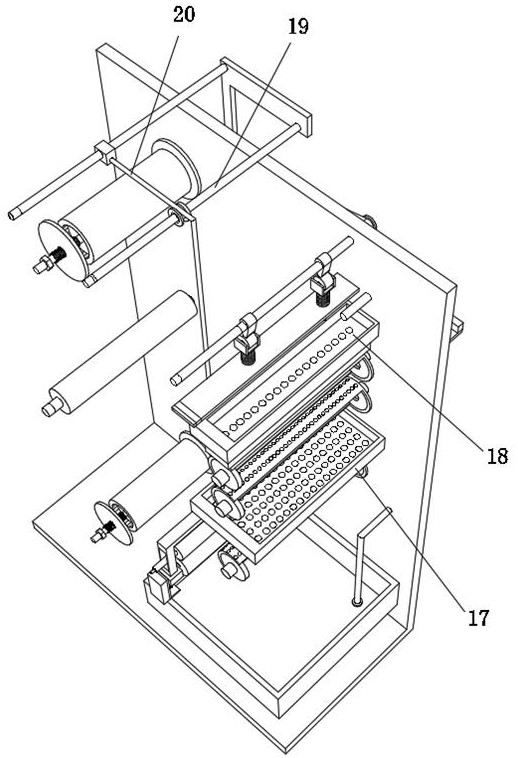

[0037] A wetting device for weaving textile fabrics for weaving, such as Figure 1-5 As shown, it includes a wetting frame 1 and a textile cloth winding mechanism. The inner walls on both sides of the wetting frame 1 are rotatably connected to the same cam column 5, and the inner walls on both sides of the wetting frame 1 are fixed with guard plates 28 by bolts. The top outer wall of the guard plate 28 is slidingly connected with two roller connecting posts 27, and the inner wall of the top of the two roller connecting posts 27 and the top outer wall of the guard plate 28 are snapped with a spring one 29, and the two rollers are connected to each other. The outer wall of the bottom of the column 27 is fixed with the same primary water receiving tank 18 by bolts, the outer wall of the bottom of the primary water receiving tank 18 is bonded with a water-absorbing sponge 30, and the inner walls of the two sides of the wetting frame 1 are respectively rotated and connected with a h...

Embodiment 2

[0044] A wetting device for weaving textile fabrics for weaving, such as Figure 8As shown, in order to ensure the smoothness and wetness of the remaining textile cloth after cutting the textile cloth; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of one side of the limiting plate 10 is clamped with a spring three 42 , and the end of the spring three 42 far away from the limiting plate 10 is clamped on the outer wall of the rack plate 16 side; Winding a certain length of textile cloth, cutting the textile cloth, thereby replacing the winding sleeve 25, wetting the remaining textile cloth on the winding sleeve one 3 and using a new winding sleeve again Tube two 25 is rolled, because spring three 42 is in compressed state in the process of one end of rack plate 16, so after the textile cloth is cut, winding sleeve one 3 circumference outer wall is owing to lost the tension force of textile cloth, will make The spring 3 42 resets, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com