Marking pen cleaning agent and preparation method thereof, and marking pen mark cleaning method

A marker pen and cleaning agent technology, applied in the field of cleaning agents, can solve the problems that oily marker pen marks cannot be cleaned thoroughly, cleaning effect is not ideal, ink is exposed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

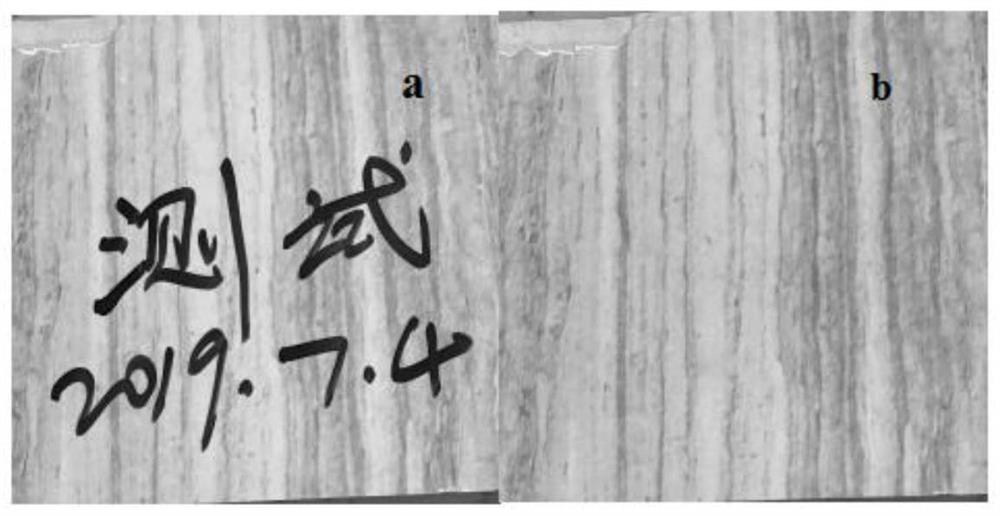

Image

Examples

preparation example Construction

[0052] The present invention also provides the preparation method of marker pen cleaning agent described in above-mentioned technical scheme, comprises the following steps:

[0053] Mix the dibasic ester solvent, n-bromopropane, ethylene glycol phenyl ether, dimethyl carbonate and D-limonene to obtain component A;

[0054] Mix the decolorizer, sodium dodecylbenzene sulfonate, tetraacetylethylenediamine, water and stabilizer to obtain component B, and obtain the marking pen cleaning agent.

[0055] The invention mixes divalent ester solvent, n-bromopropane, ethylene glycol phenyl ether, dimethyl carbonate and D-limonene to obtain component A.

[0056] In the present invention, the mixing sequence of the divalent ester solvent, n-bromopropane, ethylene glycol phenyl ether, dimethyl carbonate and D-limonene is preferably: dimethyl carbonate, divalent ester solvent and Ethylene glycol phenyl ether is firstly mixed to obtain a first mixture; secondly, the first mixture, n-bromopro...

Embodiment 1

[0065] A component contains the following components in mass percentage:

[0066] 40% dimethyl succinate, 30% n-bromopropane, 10% dimethyl carbonate, 10% ethylene glycol phenyl ether, 10% D-limonene.

[0067] Component B contains the following components in mass percentage:

[0068] 30% sodium peroxide, 3% sodium dodecylbenzenesulfonate, 0.7% sodium silicate hydroxyethylidene diphosphonic acid, 1% tetraacetylethylenediamine and 65.3% water.

[0069] Preparation method of component A:

[0070] Add the above-mentioned dimethyl carbonate, dimethyl succinate and ethylene glycol phenyl ether into the reaction kettle, and stir until they are evenly mixed to obtain a mixture;

[0071] Add the obtained mixture, D-limonene and n-bromopropane into the reaction kettle, and stir until they are evenly mixed to obtain component A.

[0072] B component preparation method:

[0073] Add the above water, sodium dodecylbenzenesulfonate, tetraacetylethylenediamine and sodium silicate hydroxye...

Embodiment 2

[0078] The difference between this embodiment and embodiment 1 is:

[0079] A component contains the following components in mass percentage:

[0080] 30% dimethyl glutarate, 40% n-bromopropane, 10% dimethyl carbonate, 10% ethylene glycol phenyl ether, 10% D-limonene.

[0081] Component B contains the following components in mass percentage:

[0082] 20% sodium peroxide, 5% hydrogen peroxide, 3% sodium dodecylbenzenesulfonate, 0.7% aminotrimethylenephosphonic acid, 1% tetraacetylethylenediamine and 65.3% water.

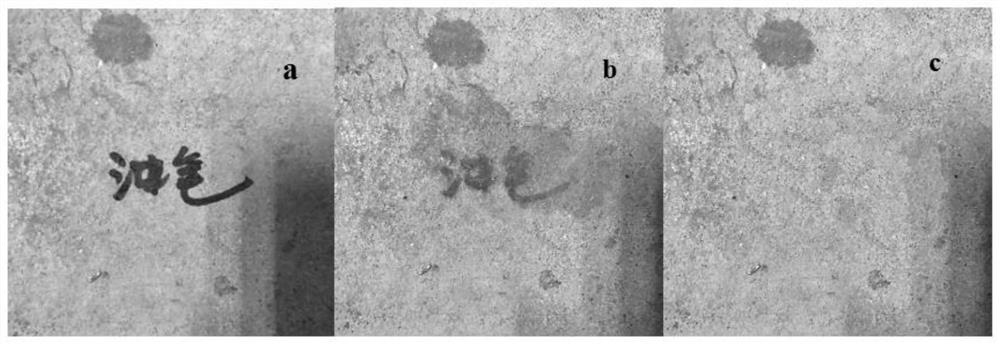

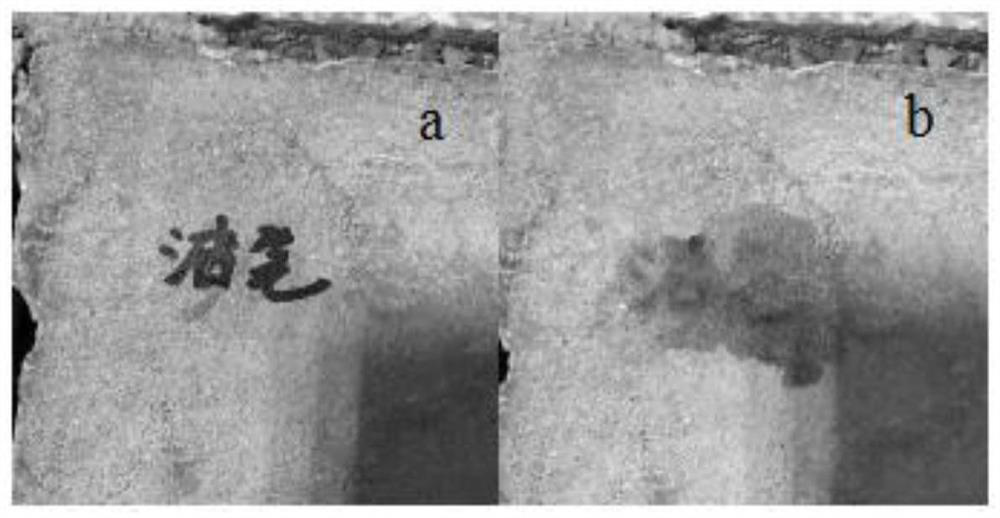

[0083] Spray the prepared component A onto the surface of the cement wall marked with a marker pen mark. After the mark pen mark dissolves and wipe the mark pen mark, spray the prepared component B onto the surface of the residual mark. After it dries naturally, wash off the remaining marks.

[0084] figure 2 It is the photo of the cleaning effect of the marking pen cleaning agent prepared in Example 2 on the marking pen imprint on the surface of the cement wall,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com